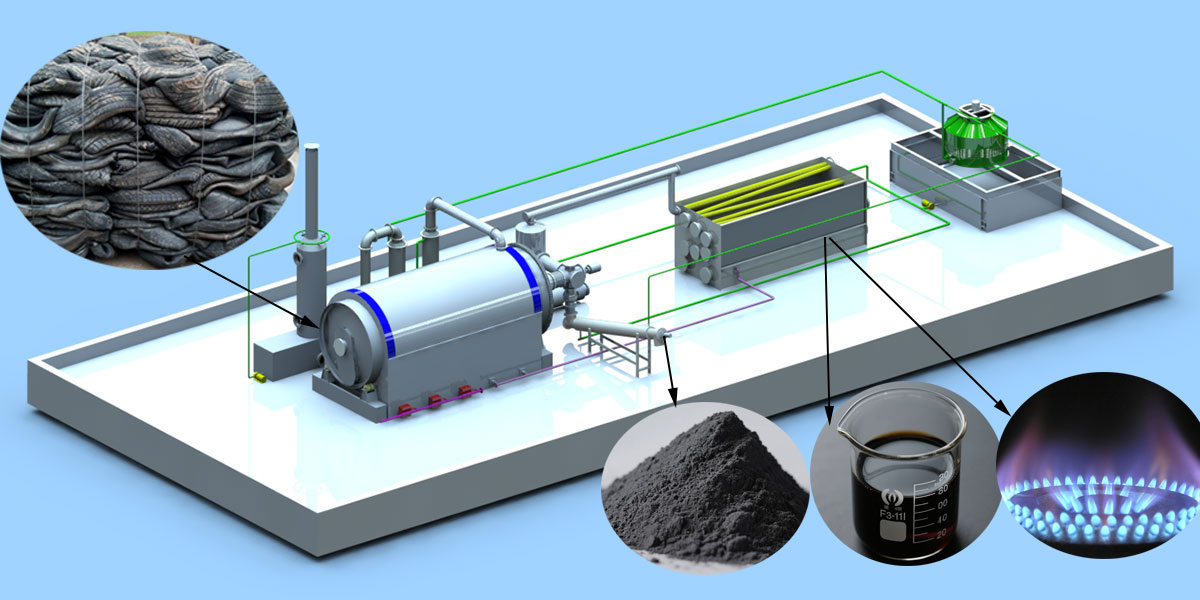

Rubber pyrolysis plant has become a key solution to the problem of rubber solid waste. It uses waste tires, hoses, seals, and other rubber products as raw materials. Through pyrolysis technology, the rubber pyrolysis plant converts waste rubber into fuel oil, combustible gas, and solid carbon black.

Pyrolysis has proven to be a promising method for solid waste treatment. Mingjie batch pyrolysis plant and continuous pyrolysis plant are suitable for treating waste plastics, waste rubber, and municipal waste. The biomass carbonization plant is suitable for treating energy-rich organic solid wastes, such as agricultural and forestry waste, animal manure, and sludge.

Rubber products are ubiquitous in modern industry and daily life, such as automobile tires, rubber seals, and rubber shoes and gloves. They provide convenience and security for our travel, production, and daily lives. However, as the use of rubber products continues to rise, so too does the amount of waste rubber generated.

Rubber pyrolysis plant offers a new, green and efficient way to process waste rubber. It is of great significance for solving waste rubber pollution, resource recycling and environmental protection.

Rubber Pyrolysis Plant for Resource Recycling

Compared to incineration (energy recovery) or landfill, rubber pyrolysis plant offers a significantly higher resource conversion rate. It simultaneously produces three primary recyclable products: pyrolysis oil, carbon black, and syngas.

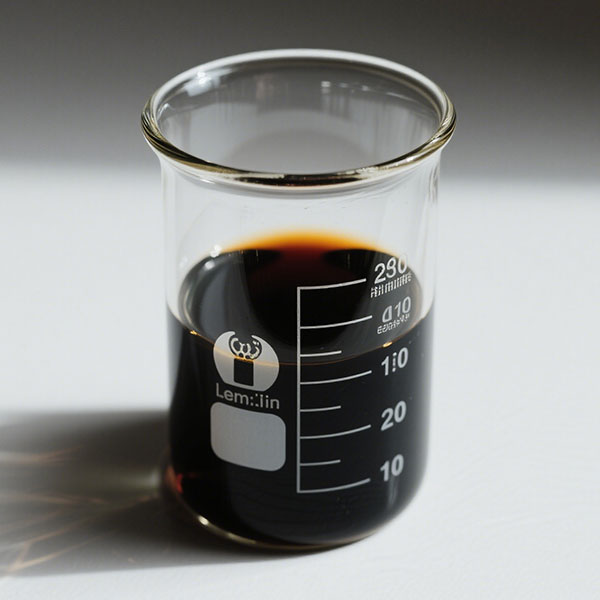

Pyrolysis oil, which can be used as a liquid fuel/chemical feedstock, is one of the most valuable products of rubber pyrolysis. The pyrolysis equipment breaks down rubber macromolecules into a liquid hydrocarbon mixture. Its calorific value is comparable to that of traditional fuel oil, allowing it to be directly used as fuel in industrial boilers and kilns. Further processing of the pyrolysis oil can also yield high-value-added chemical products.

Pyrolytic carbon black is a solid material. Rubber pyrolysis equipment can fix the carbon in rubber into solid carbon black. The quality of pyrolytic carbon black is slightly lower than that of virgin carbon black. After modification, recycled carbon black can be widely used as a reinforcing filler in the rubber and plastics industries. It can also be processed into activated carbon or used as a solid fuel.

Pyrolysis gas is composed of various combustible gases and can be used as a gaseous fuel. The non-condensable combustible gases (such as methane, hydrogen, and CO) produced during the reaction have a significant calorific value. Continuous pyrolysis plant can recover the synthesis gas and use it directly to provide heat for the pyrolysis reactor. This significantly reduces operating costs and improves economic viability.

Pyrolysis Plant for Environmental Protection

The rubber pyrolysis plant significantly reduces the volume of waste rubber and renders it harmless. While recycling resources, the pyrolysis plant also completely resolves the environmental issues associated with waste rubber. The pyrolysis equipment can reduce the volume of scrap tires by over 60%, leaving only minimal inorganic residue, fundamentally eliminating land occupation issues.

The pyrolysis process for waste rubber is clean, and secondary pollution is manageable. The pyrolysis plant operates in an oxygen-deficient, closed environment, fundamentally avoiding the formation of highly toxic substances such as dioxins.

Mingjie Group equips the pyrolysis plant with a comprehensive exhaust gas purification system, including spraying, dust removal, and alkaline solution neutralization. This ensures that the final exhaust gas meets environmental standards and prevents secondary pollution.

The rubber pyrolysis plant can process not only tires, but also a variety of mixed and contaminated rubber products, such as hoses, seals, and conveyor belts. It can even process some plastic waste, reducing the need for stringent waste sorting.

The rubber pyrolysis plant achieves a triple advantage in environmental, economic, and social benefits while processing solid waste. It is one of the key technologies and equipment to promote green, low-carbon, and circular development.