The scrap tyre recycling plant utilizes mechanical recycling and pyrolysis technology to achieve resource utilization, ensuring an environmentally friendly and efficient process. The following are the main processing steps and methods:

Pretreatment Stage

Sorting

When tires arrive at a scrap tyre recycling plant, they go through pre-processing. This stage begins by sorting them based on their type (e.g., car, truck, or motorcycle) and size. Different types of tires require different recycling methods due to their different composition.

Crushing

After sorting, the tires are fed into shredders. These machines break the tires into smaller pieces. This initial crushing not only makes subsequent processing easier, but also helps separate the different components of the tire.

Separating Metals

After crushing, the rubber chips go through a magnetic separator. This critical step is designed to remove metals. After magnetic separation, the rubber chips are further processed to remove non-metallic impurities such as textile fibers. High-purity rubber products are obtained using advanced purification technologies such as screening and air separation.

Core Processing Technology of Scrap Tyre Recycling Plant

Granulation and Product Manufacturing

The cleaned rubber crumbs are then fed into a granulator to be made into fine granules, or rubber crumbs. These granules have a wide range of uses.

One of the most common uses is in the production of rubber mulch, which is widely used in landscaping and playground surfaces. It provides a soft, shock-absorbing surface while also being resistant to weather and pests.

In the construction industry, rubber crumbs are used as an additive to asphalt in road construction. This improves the durability and performance of asphalt, reduces cracking, and extends its service life.

Recycled rubber is also used to manufacture new tires and various automotive parts, such as gaskets and seals. It is also used in the production of building products such as roofing materials, sealants, and insulation.

Pyrolysis Technology

Scrap Tyre Recycling Plant utilizes more advanced processes, such as pyrolysis technology. Tyre pyrolysis is a process that decomposes tires in the absence of oxygen to produce oil, gas, and carbon black. The tyre pyrolysis plant can converts tires in a 400-800℃ closed reactor to produce pyrolysis oil (40-45%), carbon black (30-35%), steel wire (15%), combustible gas (10%).

The pyrolysis oil produced by waste tire pyrolysis is used as industrial boiler fuel and refined into diesel by pyrolysis oil distillation plant. Carbon black is used in tire recycling, inks, and coatings. Steel wire is used as a metallurgical raw material (with a recovery rate of up to 99%). Combustible gas provides self-sustaining energy for the pyrolysis system.

Advantages: Achieve nearly 100% resource utilization, but strict pollution control (dioxin and other waste gas treatment) is required.

Using pyrolysis to process scrap tires at scrap tyre recycling plant requires significant capital investment. This includes the initial investment in a fully continuous pyrolysis plant and the high operating costs associated with energy consumption.

Direct Utilization

Whole tires are used directly in engineering applications such as breakwaters, artificial reefs, and retaining wall fill.

Heat Energy Utilization

They can replace coal combustion in cement plants and power plants (high calorific value approximately 8,000 kcal/kg). Scrap tyre recycling plants must be equipped with exhaust gas purification systems to control sulfur oxide emissions.

Environmental Protection and Safety Measures

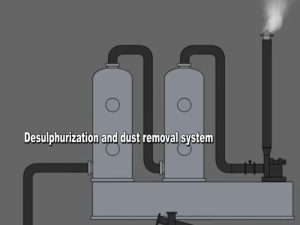

Waste Gas Treatment: The pyrolysis and incineration processes are equipped with desulfurization towers, activated carbon adsorption, and electrostatic precipitators.

Wastewater Recycling: Washing wastewater is recycled after sedimentation and filtration.

Solid Waste Management: Residual impurities (such as fibers) are sent to a waste incineration plant for disposal.

In Summary

The scrap tyre recycling plant utilizes a series of well-organized, innovative, and efficient processes to transform scrap tires into a valuable resource. From pre-treatment to component separation and product manufacturing, each step is carefully designed to ensure efficient and sustainable recycling of scrap tires. With continued advancements in pyrolysis technology, the efficiency of tire recycling plant is expected to increase further.