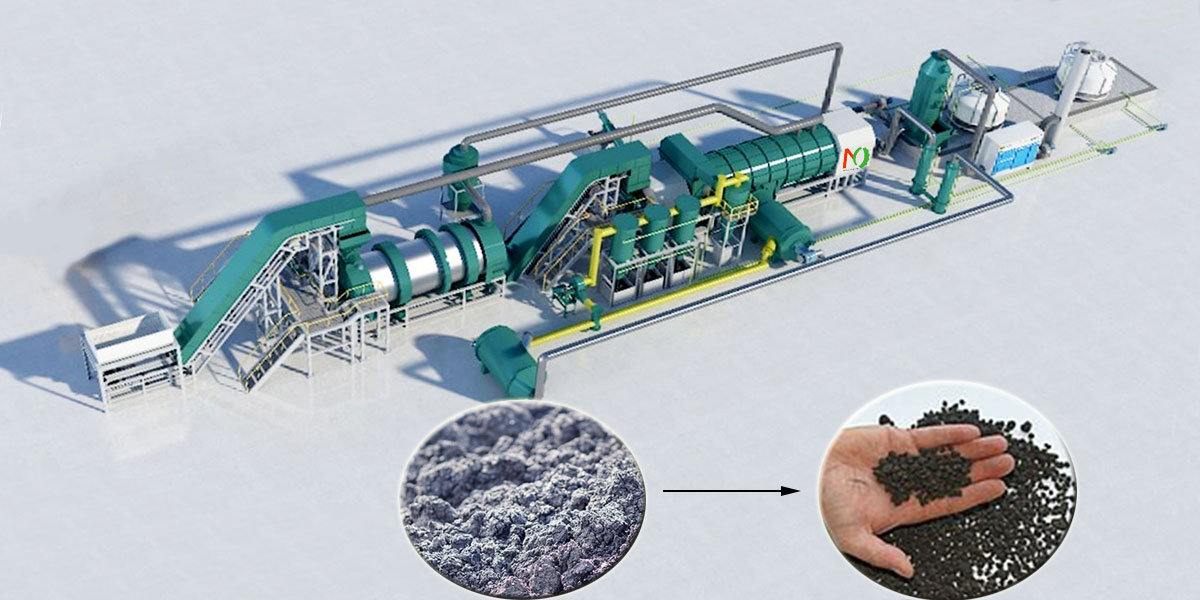

Sludge carbonization is an advanced sewage sludge treatment technology with significant potential and significance in environmental protection and resource utilization. In an oxygen-deficient or oxygen-free environment, it converts organic matter in sludge into stable biochar, tar, and syngas at high temperatures (350-700°C). As a new type of thermochemical conversion technology, sludge carbonization technology has the advantages of reduction, stabilization, harmlessness and resource utilization.

This pyrolysis carbonization technology is gaining increasing attention and application worldwide. It offers numerous advantages, including volume reduction, product resource utilization, effective heavy metal fixation, and reduced greenhouse gas emissions. The combustible gas produced by sewage sludge pyrolysis carbonization is used for energy production, while the solid char is used in building materials, soil conditioners, and adsorbents.

What is Pyrolysis Carbonization?

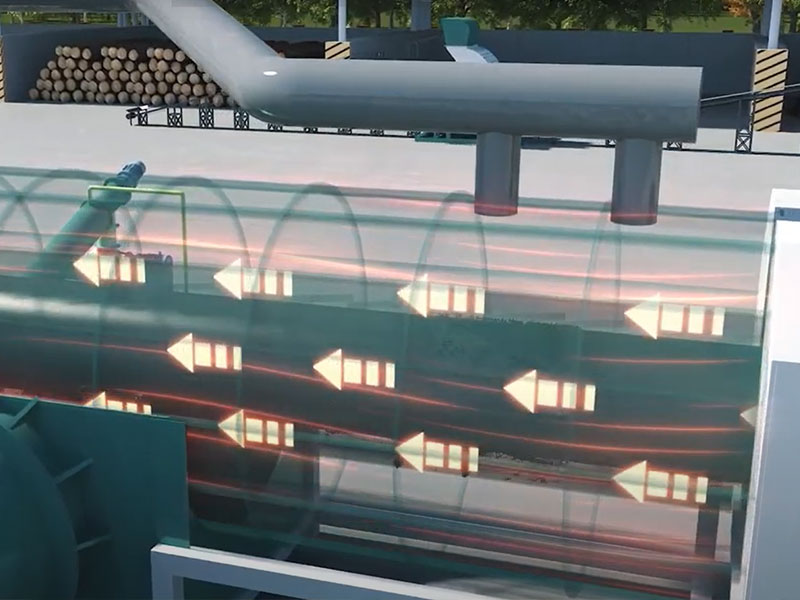

Pyrolysis carbonization involves heating biomass at high temperatures in an oxygen-deficient environment. During this process, organic carbon compounds are converted into synthesis gas and solid elemental carbon.

Although organic carbon compounds are biodegradable and release greenhouse gases into the atmosphere during their natural decomposition. But elemental carbon can remain stable for thousands of years. As long as this carbon is not burned, it does not react with any other elements. Instead, it remains in a stable form of carbon called biochar.

Therefore, when biochar is applied to soil, it can be considered a permanent carbon sink.

Sludge Pyrolysis Carbonization Projects

Sludge pyrolysis carbonization projects typically have been operating for several years, with large treatment scales and a high level of technological maturity.

Japan is one of the countries with the most successful commercialization of sludge pyrolysis carbonization technology. Many wastewater treatment plants use biomass carbonization plant to process hundreds of tons of dry solids daily.

The pyrolysis gas and oil produced by sludge carbonization are typically burned to provide heat for the pyrolysis process itself. Excess heat can also be used to dry the sludge, reducing external energy consumption. Biochar is primarily used as a fuel and raw material replacement in cement plants, for green space and farmland soil improvement, and as a landfill cover material.

European sewage sludge carbonization projects place a strong emphasis on phosphorus recovery. Sludge biochar is a significant source of phosphorus, and European countries have policies promoting phosphorus recovery from sewage sludge ash or biochar. The pyrolysis process effectively concentrates phosphorus and destroys organic pollutants, creating conditions for subsequent phosphorus extraction.

Sludge pyrolysis carbonization projects are growing rapidly in the United States, particularly in regions with strict environmental regulations, such as California and Florida. Policies prohibiting ocean dumping and restricting landfills are driving the development of pyrolysis carbonization technology. Concurrently, concerns about carbon sequestration and soil health are driving market demand for biochar production.

Advantages of Sewage Sludge Carbonization

Sewage sludge carbonization offers a safe and cost-effective circular economy solution. Recycling sewage sludge through pyrolytic carbonization yields high-quality biochar. This biochar contains valuable phosphorus, a nutrient essential for plant growth. Phosphorus-rich biochar provides both agricultural benefits and carbon sequestration in the soil.

Significant Environmental Benefits

One of the most prominent advantages of sludge carbonization is its significant environmental benefits. First, it significantly reduces sludge volume. After carbonization, the volume of sludge can be 70%-90% smaller than that of the original sludge. This avoids the environmental pollution problems caused by long-term sludge landfill, such as soil and groundwater contamination.

Second, the combustible gases produced during sludge carbonization are primarily composed of methane, hydrogen, and carbon monoxide. After purification, these gases can be used for power generation or heating. This not only achieves energy recycling, but also reduces the consumption of fossil fuels such as coal and natural gas. This reduces carbon dioxide greenhouse gas emissions and contributes to the goal of global carbon neutrality.

Resource Recycling

Sludge carbonization achieves high-value recycling of sludge resources. The solid char produced by carbonization equipment has a porous structure, a large specific surface area, and a considerable adsorption capacity. It can be used as an adsorbent to treat wastewater and exhaust gases, replacing traditional activated carbon.

Sludge carbon can also serve as a soil conditioner. It improves the physical and chemical properties of the soil, enhances its ability to retain water and fertilizer, and provides trace elements necessary for crop growth. It also promotes the activity of microorganisms in the soil, thereby improving soil quality and increasing crop yields.

The liquid tar produced during the carbonization process can be further processed and refined. It can be used as a raw material for the production of chemical products such as phenol and naphthalene.