Waste ship oil sludge refers to the large amount of complex waste oil sludge generated during navigation, maintenance, and oil storage. It mainly originates from oil stains in the engine room hull, fuel purification residue, and lubricating oil replacement waste. Furthermore, due to the unique operating environment of ships, the waste oil sludge also contains impurities such as seawater salt, metal shavings, and rust-preventive coating particles.

According to statistics from the International Maritime Organization (IMO), the total amount of waste oil sludge generated by ships globally exceeds one million tons annually. Pyrolysis plants can convert this waste oil sludge into sustainable liquid fuels with performance comparable to diesel.

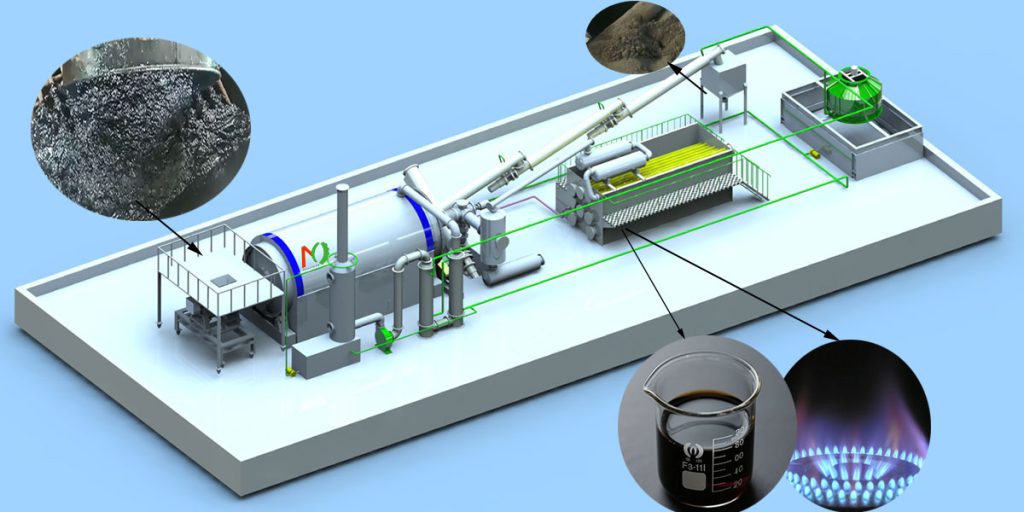

The core principle of ship waste oil sludge pyrolysis technology is to allow the organic matter in the waste oil sludge to undergo a pyrolysis reaction in an oxygen-free, high-temperature environment. Ultimately, the waste oil sludge is converted into three products: fuel oil, syngas, and carbon black residue.

Unlike conventional oil sludge pyrolysis, ship waste oil sludge pyrolysis requires addressing two major issues:

First, the corrosion of equipment by seawater salinity. Therefore, the inner wall of the pyrolysis reactor is typically made of corrosion-resistant alloy materials or coated with an anti-corrosion coating.

Second, the interference of metallic impurities on the pyrolysis process. Pre-treatment processes such as screening and magnetic separation are used to remove metal debris in advance, preventing it from reacting with the reactor wall at high temperatures or clogging pipes.

Waste Oil Sludge Pyrolysis Treatment Process

Pretreatment

Dewatering: Most of the free water in the sludge is removed mechanically (centrifuge, filter press), reducing energy consumption in subsequent treatments.

Homogenization: Ensures relatively uniform material composition and particle size entering the pyrolysis furnace, guaranteeing the stability of the pyrolysis process.

Feeding System

The pretreated sludge is continuously and stably fed into the pyrolysis reactor via a screw feeder, preventing air from entering the system.

Pyrolysis Reaction

The sludge is indirectly or directly heated to the target temperature (typically 450℃ – 600℃) in the pyrolysis reactor. In an oxygen-deficient environment, large organic molecules in the sludge undergo chain breakage and decomposition, transforming into smaller gaseous and liquid products.

Product Recovery and Separation

Pyrolysis Oil: The condensed liquid product is pyrolysis oil. It is a complex mixture that can be used as fuel oil or further refined to improve its quality by distillation plant.

Non-condensable gas (syngas): The high-temperature oil-gas mixture exiting the reactor first passes through a condenser. Non-condensable gases, such as hydrogen (H₂), methane (CH₄), and carbon monoxide (CO), are separated. The syngas has a high calorific value and is typically returned to the combustion chamber as fuel, providing heat for the pyrolysis process and achieving energy self-sufficiency.

Solid Residue (Carbon Black): The solid material remaining after the reaction mainly contains inorganic matter, carbon black, and potentially enriched heavy metals. Characteristic analysis is required to determine whether it should be safely landfilled or recycled (as an additive in building materials).

Exhaust Gas Treatment

The combustion exhaust gas that provides the heat source for the pyrolysis system, as well as any small amounts of gas that may escape from the system, must be ensured to meet emission standards before being discharged. These gases need to be treated by purification facilities such as cyclone dust collectors, spray towers, and activated carbon adsorption.

Pyrolysis Advantages of Waste Ship Oil Sludge

The pyrolysis technology for ship waste oil sludge has become the industry’s preferred solution due to its dual advantages in environmental protection and economics.

Environmental Advantages: From Marine Pollution to Zero Secondary Pollution

Compared to traditional disposal methods, pyrolysis technology operates in an anaerobic environment, effectively avoiding the formation of dioxins during incineration. Exhaust gas undergoes multiple purification processes to meet emission standards, resulting in no air pollution. Solid residues, after classification and treatment, avoid soil and groundwater pollution caused by landfilling.

Most importantly, pyrolysis technology enables closed-loop management of ship waste oil sludge, from “onboard collection to port disposal.” This reduces illegal discharges at sea at the source, protecting the marine ecosystem.

Economic Advantages: From Disposal Costs to Resource Benefits

The hydrocarbons in ship waste oil sludge, after pyrolysis, can be converted into high-value pyrolysis oil and pyrolysis gas. Pyrolysis oil can be used as ship fuel or sold to refineries. Pyrolysis gas can directly power the pyrolysis system, reducing external energy consumption. The separated carbon black can also be sold as an industrial raw material, forming a virtuous cycle of disposal, recycling, and revenue.

Flexibility Advantage: Adaptable to Multiple Application Scenarios

Given the dispersed nature of shipboard waste oil sludge generation, pyrolysis equipment can be designed as both fixed port processing stations and mobile shipboard processing units. Fixed processing stations are built in major ports to handle the waste oil sludge disposal needs of ships arriving at port. Mobile pyrolysis unit can be installed on dedicated workboats to provide on-site disposal services for ships unable to dock. This solves the problems of difficult collection and expensive transportation of shipboard waste oil sludge.