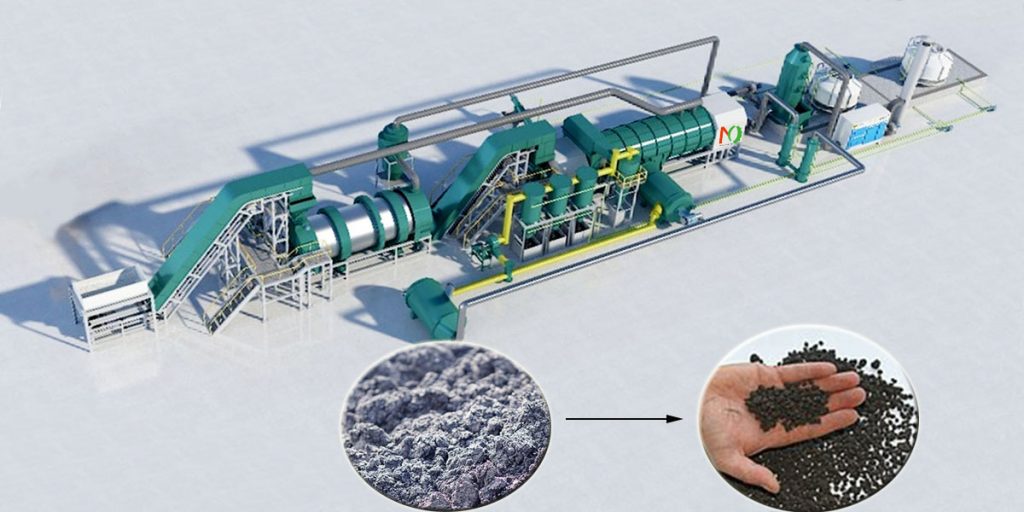

In recent years, pyrolysis carbonization technology has developed rapidly, achieving the reduction and resource utilization of sludge. Biomass pyrolysis equipment converts sludge into a high-value functional material, with sludge biochar as the main solid product.

Sewage sludge biochar typically possesses a well-developed porous structure, a large specific surface area, abundant surface functional groups, and a high ash content. These characteristics make it an excellent carrier for adsorption and catalytic reactions.

Modified sewage sludge biochar has promising applications in the in-situ remediation of polluted water bodies. On the one hand, sludge-based biochar (SBC) has a certain capacity to adsorb emerging contaminants (ECs). On the other hand, SBC has strong ion exchange capacity and water retention properties, which can fix various catalysts and enhance the advanced oxidation treatment of ECs.

Production Process of Sludge Biochar

Municipal sludge has a complex composition, mainly consisting of microbial flocs, organic fragments, inorganic particles, heavy metals, and pathogens. Its inherent physicochemical characteristics are crucial factors determining the quality of biochar.

Before pyrolysis, the sludge must undergo necessary pretreatment. Dehydration and drying reduce the water content of the sludge, and then crushing improves the uniformity of the material.

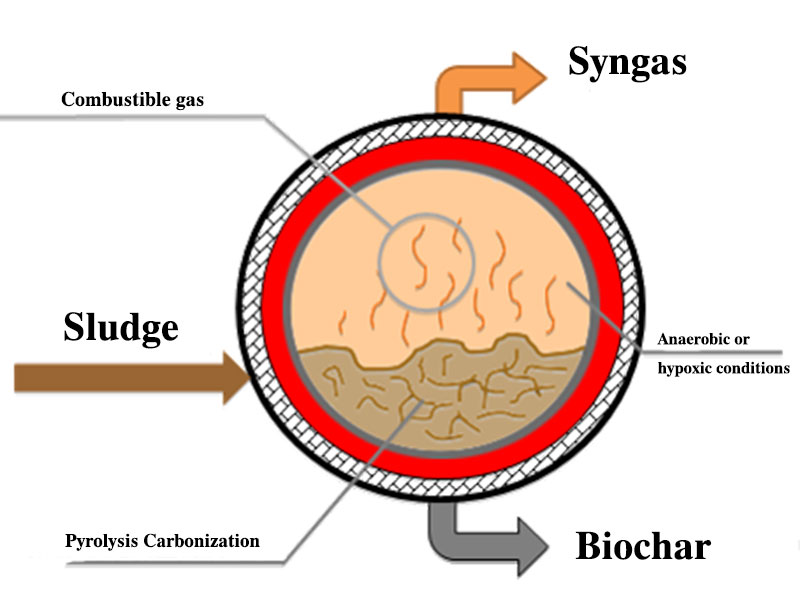

Pyrolysis carbonization is the core step in the preparation of sludge biochar. The pyrolysis process refers to the process in which sludge is heated and decomposed in an oxygen-free or low-oxygen environment, producing biochar, condensable liquids, and gaseous products. This process transforms the organic matter in the sludge into biochar with a large specific surface area, well-developed pore structure, and high carbon content.

Sludge pyrolysis also produces tar and potentially harmful gases. The exhaust gas treatment system is an indispensable part of the sludge pyrolysis and carbonization process. The exhaust gas treatment process typically involves “high-efficiency dust removal → acidic gas removal → VOCs and exhaust gas treatment → compliant discharge through a chimney.”

In the sludge biochar production process, energy balance is also crucial. Recovering the heat generated from the combustion of pyrolysis gas can be used for sludge drying or carbonization processes. This improves the energy self-sufficiency and economic efficiency of the entire biomass pyrolysis system.

Life Cycle Assessment (LCA) of Sludge Pyrolysis Project

LCA is an important tool for comprehensively assessing the environmental sustainability of this technology. It can be used to quantify the energy consumption, resource consumption, and environmental impact of the entire technological chain. Covering all stages, including sludge transportation, drying, pyrolysis, modification, application, and subsequent disposal.

Sludge pyrolysis typically involves the high-temperature decomposition of biomass under oxygen-deficient conditions, producing oil, gas, and biochar. Sludge biochar, due to its stable structure, can serve as a long-term carbon sink.

Although the pyrolysis process requires energy consumption, SBC (sludge-based biochar) brings significant positive environmental benefits through sludge reduction, resource utilization, and carbon sequestration effects.

Advantages of Sludge Pyrolysis Carbonization Plant

- Low flue gas production and low pollutant concentration: The total amount of pyrolysis flue gas is only about 30% – 40% of that of incineration. If the pyrolysis gas is condensed to recover oil, the emissions are even lower, significantly reducing air pollution.

- Low carbon emissions: A portion of the carbon is sequestered in the carbonized product in the form of fixed carbon. The carbon emissions from sludge pyrolysis carbonization are lower than those of incineration, contributing to carbon emission reduction targets.

- Source control of dioxins: Sludge pyrolysis is carried out under anaerobic or oxygen-deficient conditions, effectively inhibiting the generation of dioxins at the source. This avoids the hazards of this highly toxic pollutant.

- Wide range of applications for sludge biochar: The carbonized product contains elements such as nitrogen, phosphorus, and potassium, and heavy metals are solidified and stabilized. It can be used in building materials manufacturing, road base materials, soil improvement, and as fuel for power plants/cement plants.