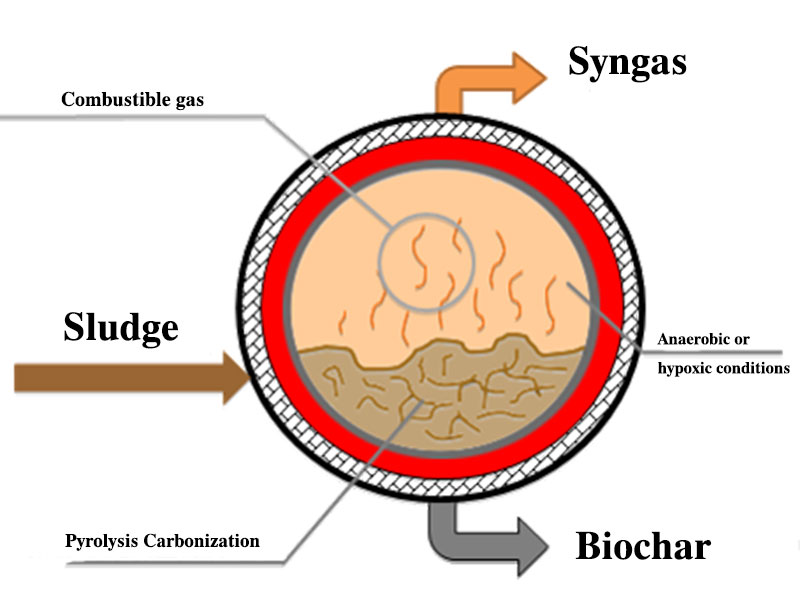

The sludge carbonization process consists of two core stages: pyrolysis and carbonization. During the pyrolysis stage, when temperatures rise to 300-600°C, the organic matter in the sludge undergoes a complex series of chemical reactions, including decomposition, cracking, and volatilization.

During the sludge stage, volatile components in the organic matter, including small hydrocarbon molecules, water vapor, and some organic compounds, are released. These components pass through a condensation system, forming combustible gases and liquid tar. The solid residue remaining after pyrolysis is called semi-coke, which still contains a certain amount of volatile matter and fixed carbon.

Subsequently, the semi-coke enters the carbonization stage, where it is further heated to higher temperatures under continuous oxygen-free or anoxic conditions. During this stage, the remaining volatile matter in the semi-coke is further removed. The carbon atoms rearrange themselves, forming a more stable carbon structure. Ultimately, the semi-coke is converted into chemically stable biochar, also known as sludge carbon.

How to Treat Sludge in Biomass Carbonization Plant

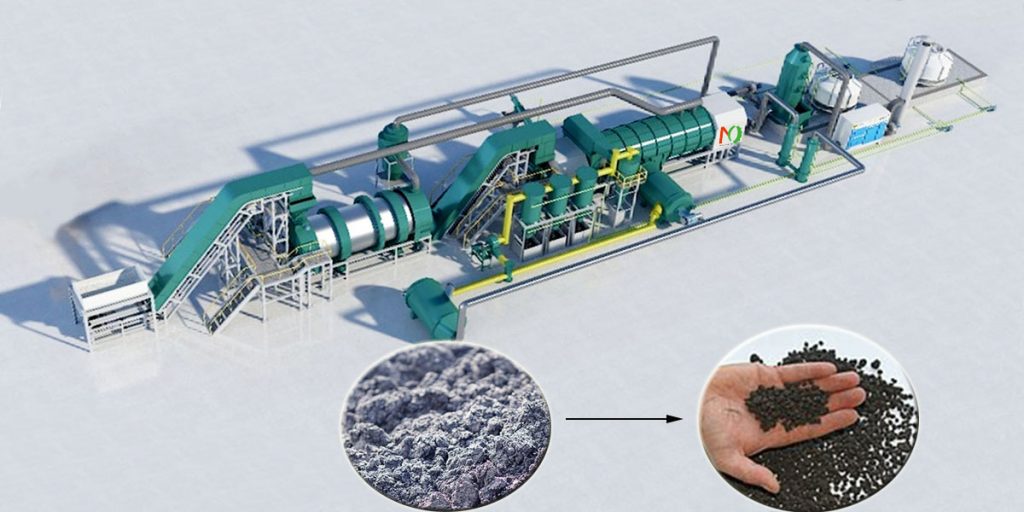

Biomass carbonization plant can not only convert agricultural and forestry waste into high-value products, but also offer unique advantages when used to treat sewage sludge. The sludge carbonization solves the challenges of sludge disposal, creating a win-win situation for environmental protection and resource utilization.

Sewage Sludge Pretreatment

Sludge pretreatment is a critical step in the sewage sludge carbonization process, directly impacting the efficiency and quality of subsequent carbonization. The pretreatment stage primarily includes dewatering, drying, and crushing.

Dewatering is the first step in pretreatment. Raw sludge typically has a moisture content of 80% to 95%. Directly feeding the sludge into the carbonization furnace requires significant energy to evaporate the water. This not only increases processing costs but also reduces carbonization efficiency. Therefore, mechanical dewatering is typically used to reduce the sludge’s moisture content to 60% to 80%.

The dewatered sludge then enters the drying process, which aims to further reduce its moisture content to below 10% to 20%. During the sludge drying process, the sludge is heated to a specific temperature to evaporate the water. The dried sludge exhibits improved fluidity and thermal conductivity. This ensures uniform heating during the subsequent carbonization process, improving carbonization efficiency.

Finally, the dried sludge is crushed. The purpose of crushing is to break up the agglomerated sludge into small particles of uniform size. This can increase the contact area between the sludge and the heat source, and promote the full decomposition of organic matter in the sludge.

Sludge Carbonization Process

Sludge Pyrolysis Stage

Sludge Pyrolysis is the core stage of the sewage sludge carbonization process. After pretreatment, the sludge is fed into a pyrolysis furnace and heated to 500-1000°C under oxygen-free or anoxic conditions. Within this temperature range, the organic matter in the sludge undergoes vigorous chemical reactions.

First, the high temperature decomposes the large organic molecules in the sludge into small organic molecules. These small organic molecules then undergo further cracking reactions, producing volatile components such as synthesis gas and liquid tar. Meanwhile, the non-volatile components in the sludge remain as char.

Sludge Pyrolysis is a complex endothermic reaction that requires continuous heat to maintain the reaction temperature. External energy (natural gas, electricity) is used as the initial heat source, and combustible gas generated during the sludge carbonization process can be used later.

To ensure the smooth progress of the sludge carbonization process, the reaction temperature, residence time, and atmosphere within the pyrolysis furnace must be strictly controlled. The reaction temperature directly affects the composition and yield of the sludge pyrolysis products. The residence time determines the degree of organic matter decomposition. The oxygen-free atmosphere in carbonization equipment can prevent the oxidation of sludge and pyrolysis products and ensure product quality.

Sludge Carbonization Stage

The semi-coke produced after the sludge pyrolysis reaction enters the carbonization furnace for further carbonization. The carbonization stage is carried out at a relatively high temperature and always in the absence or anoxic conditions.

During this stage, any volatile matter remaining in the semi-coke is further volatilized and removed. Simultaneously, carbon atoms rearrange themselves, gradually converting amorphous carbon into crystalline carbon, forming a more stable carbon structure. This carbonization process not only increases the carbon content of the solid product but also enhances its chemical stability and mechanical strength.

Carbonization temperature and residence time are key factors influencing the quality of sludge biochar. Generally, increasing the carbonization temperature and residence time increases the carbon content and decreases the volatile matter content. The adsorption capacity and electrical conductivity of the biochar also improve.

However, excessively high temperatures and excessive residence times increase energy consumption and reduce the yield of sludge biochar. Therefore, appropriate carbonization conditions must be selected based on the specific application requirements of the sludge biochar.

Product Separation

After the pyrolysis carbonization reactions are complete, the product mixture (solid carbon, combustible gases, and liquid tar) needs to be separated and collected. The product separation process primarily involves gas-solid separation and gas-liquid separation.

Gas-solid separation is the first step in product separation. The solid carbon and combustible gas mixture from the carbonization furnace is sent to a cyclone separator or bag filter. Centrifugal force or filter media separates the solid carbon from the combustible gases. The separated solid carbon is then sent to a cooling system to prevent oxidation and ensure safety.

Next is gas-liquid separation. The combustible gases separated from the solid carbon contain a certain amount of liquid tar vapor. The combustible gases are cooled to a certain temperature in a condenser, condensing the tar vapor into liquid tar, which is then separated from the combustible gases. The separated liquid tar is collected in a storage tank for further processing and utilization.