With the acceleration of industrialization and urbanization, the amount of waste generated is increasing day by day. Oil sludge and sewage sludge are two typical wastes. Sludge Treatment has become an urgent problem to be solved in the field of environmental protection. Pyrolysis technology, due to its unique advantages, provides new ideas and methods for the oil sludge and sewage sludge treatment.

Pyrolysis plant can not only reduce the volume and weight of waste and reduce its harm to the environment. It can also recover energy and valuable substances from it to achieve the recycling of resources. A deep understanding of the difference between oil sludge pyrolysis and sewage sludge pyrolysis is of great significance for optimizing the pyrolysis process and improving resource recovery efficiency.

Oil Sludge Pyrolysis

Oil sludge mainly comes from oil extraction, refining and related industrial processes. It contains a large amount of petroleum substances, heavy metals and other pollutants.

Oil sludge has a high oil content, generally between 20% and 50%. This makes the oil sludge have a high calorific value and provides a rich source of energy for pyrolysis.

The main product of oil sludge pyrolysis is pyrolysis oil. Its composition is similar to that of petroleum, mainly including various hydrocarbon compounds, and its calorific value can reach 30-40MJ/kg. Pyrolysis oil can be used directly as fuel oil, or it can be further refined by distillation plant to produce gasoline and diesel.

Sewage Sludge Pyolysis

Sewage sludge is mostly produced in sewage treatment plants. Its composition is complex, including organic matter, microorganisms, heavy metals and various chemical agents.

The oil content of sludge is low, usually below 10%. This results in a relatively low calorific value and less energy generated during pyrolysis.

The sewage sludge pyrolysis product is mainly charcoal. The calorific value of charcoal is high, and it can be used as a fuel or a reducing agent in metallurgy, chemical industry and other industries.

Sludge carbon has a large specific surface area and adsorption properties, and can be used to produce activated carbon for wastewater treatment, air purification and other fields. It can also be used as a soil conditioner to improve soil structure, increase soil fertility and increase crop yields.

Different Pyrolysis Plant for Sludge Treatment

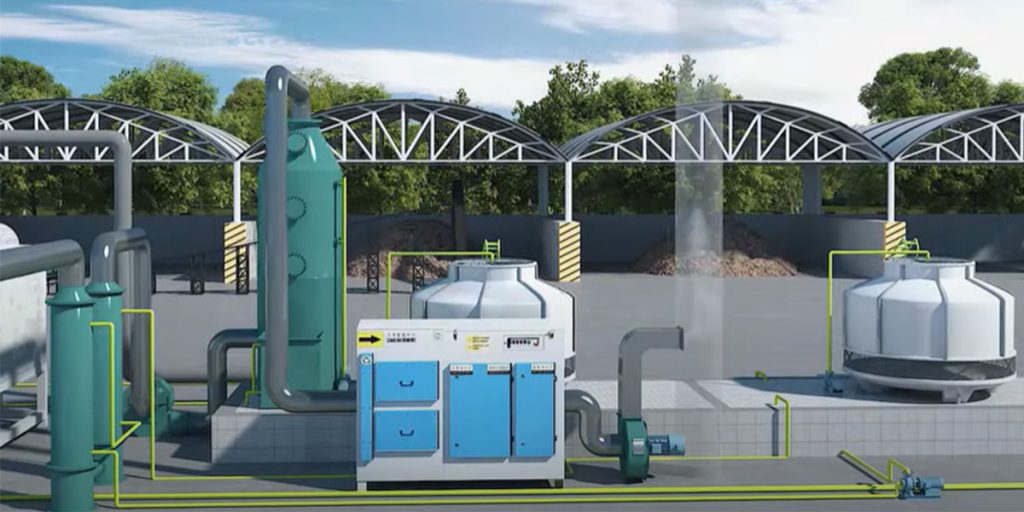

Mingjie Group provides different continuous pyrolysis plants for oil sludge disposal and sewage sludge treatment.

Pretreatment Equipment

In terms of pretreatment equipment, oil sludge needs to be dehydrated and deoiled due to its high oil content. Commonly used equipment includes centrifuges, filters, distillation towers, etc. Centrifuges can be used to separate solids and liquids from oil sludge and remove most of the water. Filters can be used to further remove solid impurities in oil sludge. Distillation towers can separate oil and water from oil sludge by distillation.

Due to the high water content of sewage sludge, it needs to be pre-treated by dehydration and drying. Commonly used equipment includes filter press, belt conveyor, dryer, etc. Filter press can squeeze out the water in sludge by applying pressure. Belt conveyor is used to transport sludge. Dryer can evaporate the water in sludge by heating to reduce the water content of sludge.

Pyrolysis Reactor

The key difficulty of the oil sludge pyrolysis reactor is to deal with highly viscous and complex oily waste. Its design needs to pay attention to anti-blocking, high-temperature pyrolysis efficiency and oil and gas recovery.

The design of the sewage sludge pyrolysis reactor focuses on sealing and achieving continuous pyrolysis and carbonization. The pathogens and odor problems of municipal sludge directly affect operators more than oil sludge. Tail gas treatment is very important.

Product Collection

In terms of oil-gas separation, the oil-gas mixture produced by pyrolysis of oil sludge is usually separated by condensation, liquid separation and other methods. The oil-gas mixture is cooled by a condenser to condense the gaseous hydrocarbons and water vapor into liquid, and then the liquid oil and water are separated by a separatory funnel.

The pyrolysis products produced by sludge pyrolysis are usually separated by condensation, filtration, liquid separation and other methods. In addition to condensation and liquid separation, solid impurities in the pyrolysis products need to be removed by filtration to improve the purity of pyrolysis oil and pyrolysis gas.

Tail Gas Treatment

In terms of tail gas treatment equipment, the tail gas produced by pyrolysis of oil sludge contains pollutants such as hydrogen sulfide, nitrogen oxides, and particulate matter. It needs to be treated with desulfurization, denitrification, and dust removal equipment. Commonly used equipment includes desulfurization towers, denitrification devices, bag dust collectors, etc.

The tail gas produced by pyrolysis of sewage sludge contains pollutants such as sulfides, nitrogen oxides, and dioxins. It need to be treated with purification equipment. Commonly used equipment includes washing towers, activated carbon adsorption devices, catalytic combustion devices, etc.