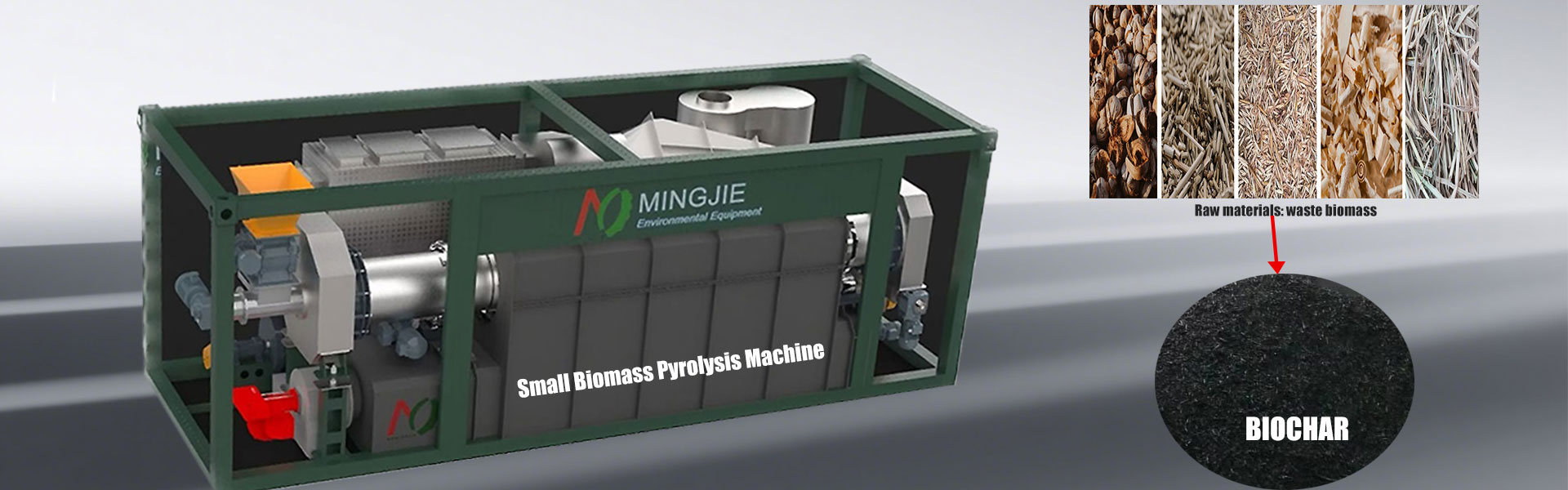

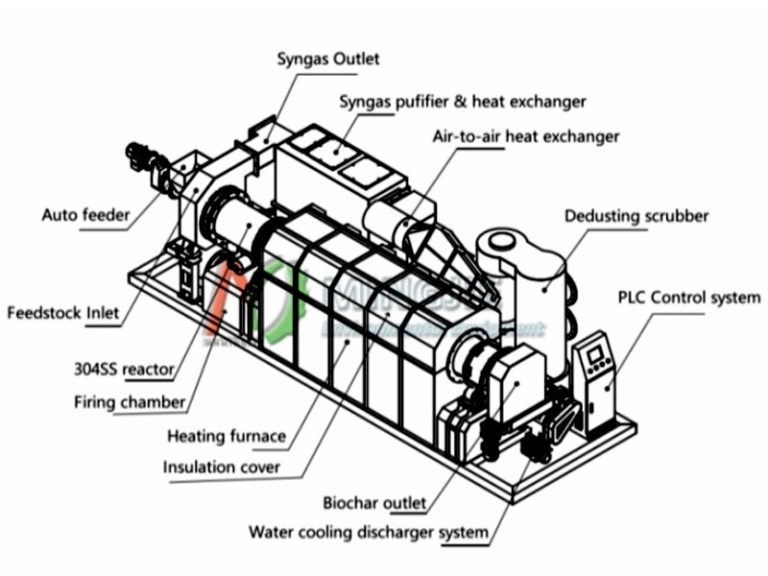

The small biomass pyrolysis machine adopts an integrated skid-mounted structure, and the capacity of processing waste biomass is 50-100kg/h. The skid-mounted carbonization equipment tightly integrates the pyrolysis reactor, cooling system, intelligent control module and purification system.

Small Biomass Pyrolysis Plant for Sale

The pyrolysis reactor is the core system and adopts a single-cylinder structure. The 304 stainless steel material enables it to withstand high temperature environments and provide a stable reaction space for biomass carbonization.

In the application of small biomass carbonization plants, the single batch processing capacity can reach 100kg/h, and the biomass conversion rate can reach more than 85%. This means that most of the biomass can be converted into valuable products, significantly improving the efficiency of resource utilization. These products not only meet part of the local energy needs, but also bring additional economic benefits.

If you are interested in purchasing or learning more about Small Biomass Carbonization Plant, you can contact Mingjie Group. Let me know if you need help finding specific models!

| Model | MJT-100 |

| Input Capacity | 50-100kg/h |

| Structure | Skid Mounted |

| Reactor Type | Single Layer |

| Working Method | Fully Continuous |

| Reactor Material | 304 Stainless steel |

| Feedstock Size | <20mm |

| Feeding Moisture | <15% |

| Initial Heating Oil Consumption | 20L |

| Land Area | L12m*W2.5m |

Biomass Pyrolysis Carbonization Project

The capacity of a single small biomass pyrolysis machine to process biomass waste can reach 100KG/H. This data means that it can efficiently process a large amount of waste and reduce the pressure on the environment caused by waste accumulation. At the same time, it can also produce synthetic gas, which is an important source of clean energy and can replace fossil fuels for power generation, heating and other fields.

The skid-mounted mobile small biomass pyrolysis machine has been designed and operated with environmental protection in mind. It is committed to reducing the generation and emission of pollutants from the source.

- In terms of zero emission control of pollutants, the pyrolysis machine can effectively inhibit the generation of dioxins through a unique chemical reaction mechanism, reducing the risk of dioxin generation from the source.

- At the same time, in order to ensure that the exhaust gas generated during the pyrolysis process can meet the emission standards, the pyrolysis machine is also equipped with a high-efficiency exhaust gas purification device.

- In terms of the low-carbon circular economy model, the skid-mounted mobile small biomass pyrolysis machine has demonstrated excellent performance.

Small Biomass Pyrolysis Machine Advantages

The various functional modules of the skid-mounted biomass pyrolysis machine are combined on a base, which enables fast installation and flexible movement.

- In rural or forest areas, when crop straw, rice husk or forestry waste needs to be processed, the biomass carbonization equipment can be quickly transported to the site and put into use after rapid installation and commissioning.

This skid-mounted design reduces the footprint of the biomass carbonization equipment. It greatly reduces the requirements for the site and can adapt to more complex site conditions.

Carbonization Principle of Biomass Pyrolysis Equipment

The small biomass pyrolysis equipment converts biomass into high-value energy biochar based on high-temperature pyrolysis technology under anoxic conditions.

When biomass raw materials such as crop straw and forestry waste enter the pyrolysis machine, they are heated to 300-800℃ in an oxygen-free or oxygen-deficient environment. In this temperature range, biomass undergoes a series of complex chemical reactions. Through pyrolysis and condensation processes, it is gradually converted into combustible gas, bio-oil and biochar.

Process Flow of Biomass Carbonization Machine

The process flow of the skid-mounted biomass pyrolysis machine includes multiple steps.

1. Raw material pretreatment. The raw materials are processed into suitable sizes and shapes through screening and crushing. This allows the subsequent pyrolysis reaction to proceed more efficiently. This is followed by low-temperature drying. This step can remove moisture from the raw materials and put them in a dry state suitable for pyrolysis.

2. Pyrolysis stage. This is the core link of the entire pyrolysis process. Under specific temperature and oxygen-free conditions, biomass undergoes pyrolysis to produce biochar, tar and synthesis gas.

3. Product separation. Through a series of physical and chemical methods, combustible gas, bio-oil and biochar are separated to achieve effective recycling of resources.