Henan Mingjie Group is committed to providing comprehensive utilization solution – pyrolysis equipment for waste to energy pyrolysis. Pyrolysis technology has broad application prospects in waste treatment, resource recovery and energy production, and is an important technical means to achieve sustainable development and environmental protection.

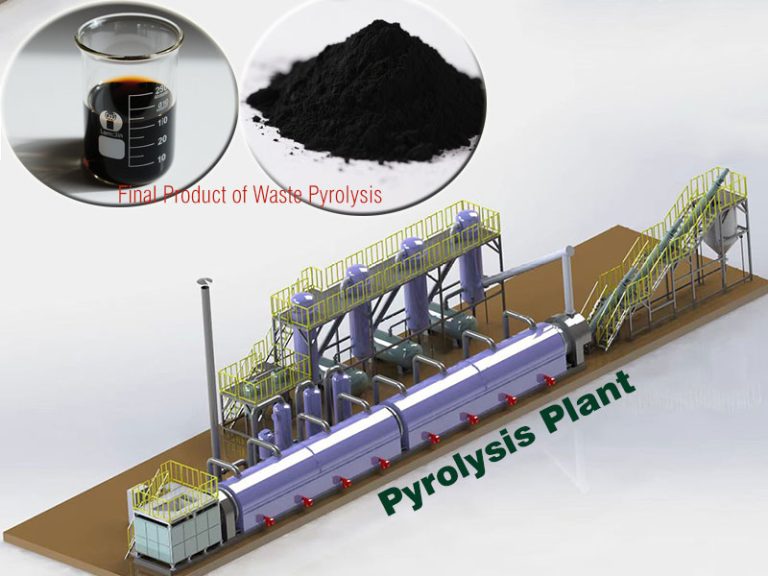

Solid Waste Pyrolysis

Mingjie pyrolysis plants can convert solid waste into energy, including fuel oil, carbon black and syngas. Pyrolysis plant for sale can be used for waste tyre/tire and plastic recycling, azardous solids oil sludge and medical waste treatment and municipal solid waste management, aluminized paper and waste cable recycling projects.

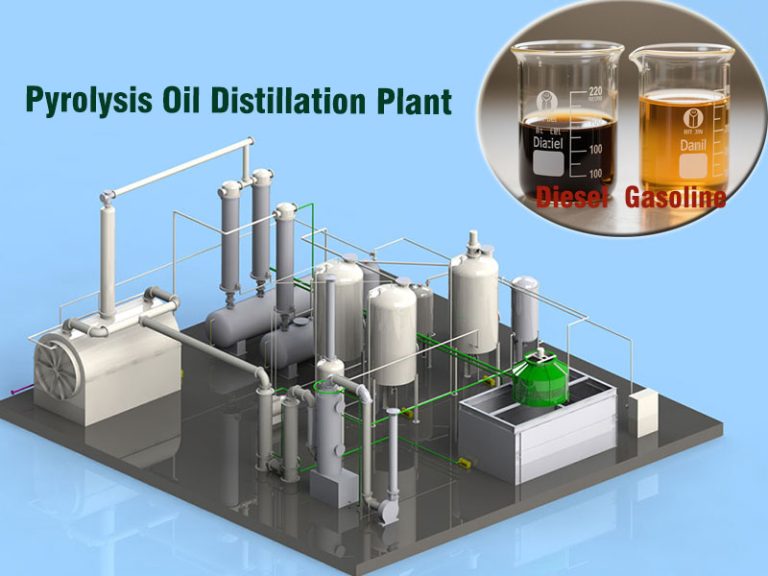

Pyrolysis Oil Distillation

Mingjie pyrolysis oil distillation plant can convert pyrolysis oil into gasoline or diesel under high temperature decomposition. Mingjie distillation equipment can be used for the treatment of waste engine oil, transformer oil, lubricating oil and the refining of pyrolysis oil.

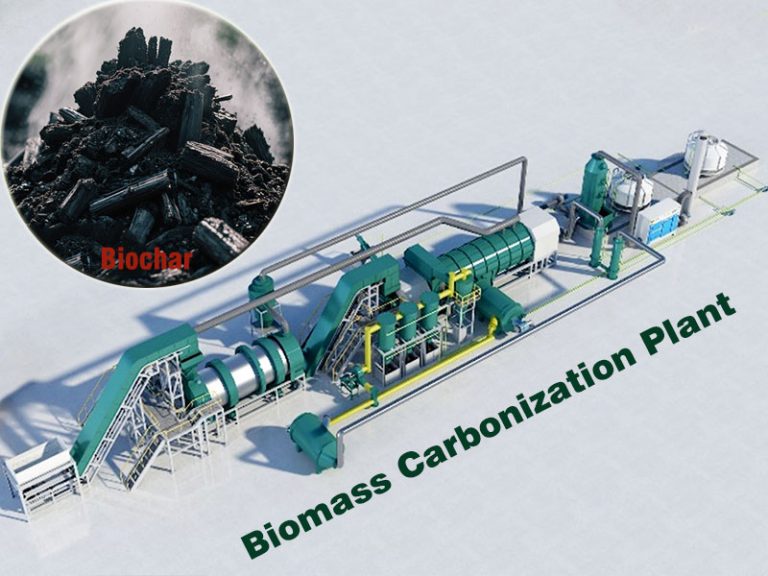

Biochar Making

Biomass carbonization plant can convert biomass materials into biochar through pyrolysis process. Our biomass carbonization equipment is widely used in the treatment of waste wood, sawdust, coconut shells, rice husks, straw and sludge.

Advantages of Waste To Energy Pyrolysis Technology

Pyrolysis waste to energy and chemical raw materials can achieve economic recovery and reduce waste treatment costs. The liquid and gas products generated can be used as raw materials in the chemical industry.

Waste Recycling

Pyrolysis plant can convert waste into reusable energy and reduce resource waste.

Pyrolysis of solid waste can effectively reduce the volume and weight of garbage, reduce the need for landfill, and reduce the environmental burden.

Pyrolysis plant can convert waste plastics and tires into pyrolysis oil and carbon black. Biomass carbonization equipment can convert biomass into highly economical biochar.

Reduce CO2 Emissions

Waste To Energy Pyrolysis is carried out under oxygen-deficient conditions, which avoids the generation of a large amount of harmful gases and smoke during the combustion process and reduces environmental pollution.

Compared with traditional incineration, the pyrolysis process can effectively reduce the emission of CO₂ greenhouse gases.

Creating New Energy

Pyrolysis products (pyrolysis oil and pyrolysis gas) can be used as alternative fuels to reduce dependence on oil and natural gas.

Biochar can be used as soil conditioner, carbon sequestration, fertilizer carrier. Biochar can be further processed into activated carbon.

Pyrolysis oil and biochar can be used as new energy fuels. They have high calorific value and can be used as clean fuel for heating or industrial heating.

Wide Range of Applications

Pyrolysis system can process many types of solid waste, including plastics, rubber, sludge, medical waste and biomass.

Pyrolysis equipment is suitable for pyrolysis of various organic wastes:

- Pyrolysis of municipal solid waste

- Pyrolysis of plastics

- Pyrolysis of rubber

- Pyrolysis of oil sludge

- Pyrolysis of biomass