The key technology supporting the operation of tire to diesel recycling plant is pyrolysis. Pyrolysis is a process that breaks down organic matter into smaller molecules under high temperatures in an oxygen-free or low-oxygen environment. For waste tires, pyrolysis effectively breaks down the complex polymer structure of the rubber in them.

The tires are fed into a sealed pyrolysis machine, where they are heated to temperatures ranging from 400-600°C. Oxygen is strictly isolated from the reactor to prevent combustion. Under the high temperatures, the rubber molecules in the waste tires undergo cracking reactions, producing a mixture of gas, liquid, and solids.

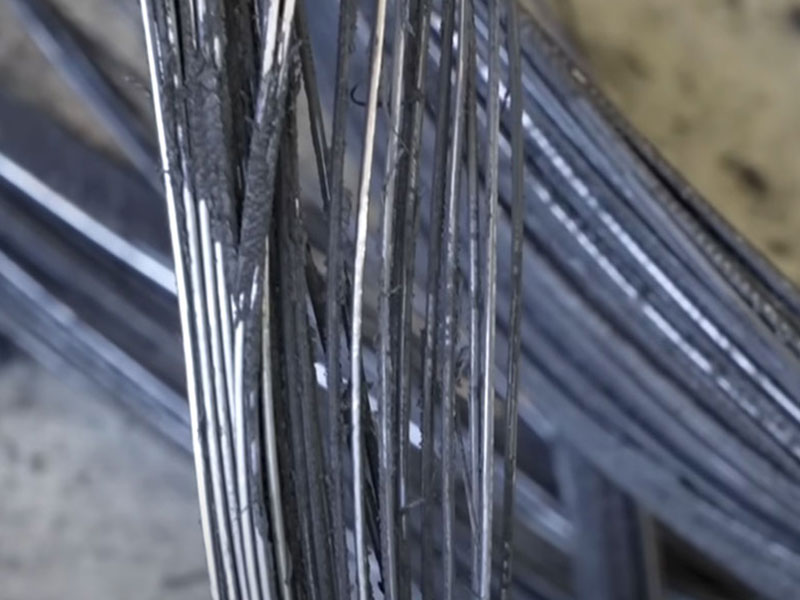

The carbon black is discharged through a slag discharger, while the solid residue remaining in the reactor is primarily steel wire. The non-condensable gases produced during the pyrolysis process, called syngas. They can be used as fuel to heat the tire pyrolysis equipment, enabling energy recycling within the tire to diesel recycling plant.

The gaseous substances are primarily small hydrocarbons. After cooling through a condensation system, they form a liquid product called pyrolysis oil. The pyrolysis oil is purified in a distillation plant to produce non-standard diesel.

Tire Oil to Diesel Process

The primary tire oil obtained has high impurity content, dark color, and a strong odor, and cannot be directly used as diesel. Therefore, it needs to go through a refining process.

The Tire Oil to Diesel refining process mainly includes the following steps.

Dehydration: The primary tire oil is heated to 100-120°C to evaporate the water.

Distillation: The dehydrated and desalted tire oil is sent to a distillation tower for distillation. The distillation tower is heated to different temperature ranges to separate different fractions.

Generally, light fractions (such as gasoline components) are separated at 150-200°C, and diesel fractions are separated at 200-360°C. The heavy fractions left at the bottom of the distillation tower can be used to produce asphalt or further processed into other chemical products.

Decolorization and deodorization: The diesel fraction obtained by distillation still contains impurities, which affect the quality and performance of diesel. Adsorbents (such as activated carbon) are used for decolorization and deodorization.

After these steps, the tire oil is converted into clear, low-odor, and qualified non-standard diesel. It can be used in diesel engines such as generators, boilers, and trucks after being mixed with standard diesel in a certain proportion.

Economic Value of Waste Tire To Diesel Recycling Plant

Waste Tire To Diesel Recycling Plant not only has significant environmental benefits, but also has considerable economic value. It is mainly reflected in the following aspects:

Low Raw Material Cost

The main raw material of the plant is waste tires. In many regions, waste tires are not only free of charge, but also require waste tire generators to pay a certain disposal fee to the recycling plant. Even in regions where waste tires need to be purchased, the price is very low, usually only 50-100 US dollars per ton. This low raw material cost lays a solid foundation for the economic benefits of the plant.

Tire Pyrolysis Product Income

The products of the tire to diesel recycling plant are not only diesel but also include carbon black, steel wire, and pyrolysis gas (used as self-use fuel). Taking a medium-sized Waste Tire To Diesel Recycling Plant with a daily processing capacity of 10 tons of waste tires as an example:

Diesel: Each ton of waste tires can produce about 0.3-0.4 tons of diesel. Based on a daily processing capacity of 10 tons, the daily diesel output is 3-4 tons. The market price of non-standard diesel is usually 70-80% of that of standard diesel. Taking the international market price of standard diesel as 800 US dollars per ton, the daily income from diesel is 3×70%×800 = 1680 US dollars to 4×80%×800 = 2560 US dollars.

Carbon black: Each ton of waste tires can produce about 0.3-0.35 tons of carbon black. The market price of refined carbon black is about 500-600 US dollars per ton. The daily income from carbon black is 10×0.3×500 = 1500 US dollars to 10×0.35×600 = 2100 US dollars.

Steel wire: Each ton of waste tires can produce about 0.08-0.1 tons of steel wire. The market price of scrap steel wire is about 300-400 US dollars per ton. The daily income from steel wire is 10×0.08×300 = 240 US dollars to 10×0.1×400 = 400 US dollars.

In addition, the pyrolysis gas generated during the tyre pyrolysis process can meet about 30-50% of the tire to diesel recycling plant fuel demand, saving a large amount of fuel costs. Comprehensive calculation shows that the annual income of a medium-sized plant can reach millions of US dollars, and the investment recovery period is usually 2-3 years.

Policy Support and Subsidies

In order to promote the development of the circular economy and solve the problem of waste tire pollution, many countries and regions have introduced preferential policies for Waste Tire To Diesel Recycling Plants. For example, some countries provide tax reductions or exemptions for the plant’s products, some provide financial subsidies for equipment purchase and plant construction, and some give priority to the plant in terms of land use and environmental permits. These policy supports further improve the economic benefits of the tire to diesel recycling plant and reduce the investment risk of investors.