Pyrolysis equipment offers new hope and solutions for municipal solid waste MSW treatment. It transforms waste into economically valuable resources such as pyrolysis oil, syngas, and carbon black, turning trash into treasure.

Municipal solid waste encompasses a wide variety of materials, including waste paper, plastics, metals, glass, kitchen waste, and hazardous waste, and its composition is extremely complex.

In the past, traditional methods for municipal solid waste treatment primarily relied on landfilling and incineration. Landfilling is a common disposal method, relatively simple to operate, requiring the waste to be deposited in designated sites. However, this method presents numerous challenges, including the significant use of valuable land resources. Furthermore, hazardous substances in the waste can gradually seep into groundwater, causing serious soil and groundwater pollution and posing a potential threat to the ecological environment and human health.

Incineration uses high temperatures to decompose organic matter in the waste, aiming to reduce its volume and render it harmless. However, improperly controlled incineration can produce highly toxic and hazardous substances, such as dioxins. The incineration residues require further treatment to prevent environmental impacts. Furthermore, the construction and operation costs of incineration facilities are high, requiring significant capital investment.

Pyrolysis plants offer significant environmental benefits and resource recovery potential, demonstrating unique value in addressing the increasingly challenging challenges of municipal solid waste. They not only effectively reduce the environmental pollution associated with traditional treatment methods but also lower the emission of harmful gases, such as dioxins.

Municipal Solid Waste Pyrolysis Principle

Municipal solid waste pyrolysis is the process of heating solid waste in an oxygen-free or oxygen-deficient environment to induce decomposition reactions within the organic matter. This MSW pyrolysis process involves a complex series of chemical reactions, primarily cracking, condensation, and recombination.

Cracking is the foundation of the pyrolysis process. Under the action of heat, the chemical bonds of large organic molecules in the solid waste break down, breaking them down into smaller molecules. Condensation, in contrast to cracking, is the process where small molecules recombine to form larger molecules. These larger molecules may have different chemical structures and properties. Recombination involves the rearrangement of atoms within molecules to form new compounds.

Turning Trash into Treasure Process

The process of turning trash into treasure through municipal solid waste pyrolysis involves several key steps, including waste pretreatment, pyrolysis incineration, and off-gas treatment. Each step is closely linked to ensure the efficiency, environmental friendliness, and resource utilization of the pyrolysis process.

Municipal Solid Waste Pretreatment

During the waste pretreatment stage, collected municipal solid waste must first be carefully sorted. This is because different types of waste vary significantly in composition and properties, and sorting facilitates targeted treatment. For example, waste paper, plastics, metals, glass, kitchen waste, and hazardous waste should be separated. This prevents interference between different materials during the pyrolysis process, which could affect the pyrolysis effect and product quality.

Pyrolysis of Municipal Solid Waste

Pyrolysis is the core step in the entire process of turning trash into treasure. Pre-treated waste is fed into a pyrolysis reactor and heated in an oxygen-free or anoxic environment. Strictly controlling the pyrolysis temperature and oxygen content is crucial to ensuring the pyrolysis reaction proceeds as intended.

Different types of waste require different pyrolysis temperatures. For example, lower temperatures may be sufficient for highly volatile organic compounds, while higher temperatures are required for more difficult-to-degrade materials.

During the municipal solid waste pyrolysis process, the organic matter in the waste decomposes to produce products, including pyrolysis oil, syngas and carbon black.

Syngas primarily consists of carbon monoxide (CO), hydrogen (H₂), and methane (CH₄). These gases have high calorific value and can be used as fuel for power generation and heating. Pyrolysis oil is a complex organic mixture that, after further distillation refining, can be used as fuel oil. The solid carbon black can be used to make adsorbents, soil conditioners, and other products.

Exhaust Gas Treatment

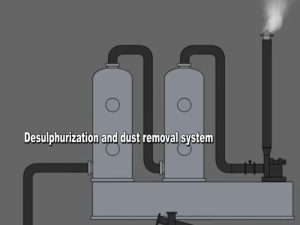

The MSW pyrolysis process generates exhaust gas, which may contain pollutants such as incompletely reacted organic matter, dust, sulfides, and nitrogen oxides. Direct discharge can cause severe atmospheric pollution. Therefore, MSW pyrolysis plant must be equipped with an exhaust gas treatment system.

Exhaust gas treatment begins with dust removal. Cyclone separators, bag filters, and other equipment can remove dust particles from the exhaust gas, making it cleaner.

Next, desulfurization treatment takes place. Absorbents such as lime milk and ammonia react with sulfides in the exhaust gas, converting them into solid or liquid sulfates, thereby reducing the sulfur content in the exhaust gas.

Denitrification treatment utilizes technologies such as selective catalytic reduction (SCR) or selective non-catalytic reduction (SNCR). It converts nitrogen oxides in the exhaust gas into nitrogen and water, reducing their environmental impact.

After these treatment steps, the pollutant content in the exhaust gas is significantly reduced. Only when it meets national emission standards can it be discharged into the atmosphere.