The tyre rubber pyrolysis process converts rubber into pyrolysis oil, synthesis gas and carbon black by heating under oxygen-free conditions. This rubber pyrolysis process is essentially to deconstruct and reorganize the hydrocarbons in the rubber, thereby realizing the recycling of waste tires. Under high temperature, the chemical bonds in the rubber molecules break, and the complex macromolecular chains gradually decompose. In the end, gas, liquid and solid products with relatively small molecular weight are formed.

Tire Pretreatment Process

The tire is large in size, which is not conducive to the subsequent pyrolysis reaction and transportation. In order to improve the efficiency of rubber pyrolysis, the tire needs to be crushed. The crusher cuts and tears the tire into smaller blocks or particles. This can ensure the uniformity and rapidity of the rubber pyrolysis process, which is convenient for subsequent transportation and processing.

In the structure of tires, steel wire is an important reinforcing material. However, during the tyre rubber pyrolysis process, the presence of steel wire will interfere with the pyrolysis reaction and affect the quality and separation effect of the product. Therefore, steel wire separation is one of the key tasks in the pretreatment stage.

At present, the commonly used method for steel wire separation is magnetic separation. Taking advantage of the magnetic characteristics of steel wire, the crushed tire particles are passed through the magnetic separation equipment. Under the action of a strong magnetic field, the steel wire is adsorbed on the surface of the magnetic separation equipment, thereby separating it from other materials.

Rubber Pyrolysis Process

The pretreated waste tires enter the reactor through the feed port, and the burner starts to heat the reactor. The reactor keeps rotating to ensure that the waste tires are evenly heated. During the rubber pyrolysis process, the high molecular polymer will undergo thermal decomposition and break into smaller molecular chains.

Three products can be obtained after waste tire pyrolysis: combustible gas, fuel oil and carbon black.

Treatment of Pyrolysis Products

Fuel oil is one of the core high value-added products of waste tire pyrolysis, with a typical yield of 35–50%. The oil and gas generated by pyrolysis are transported to the condensation system through the gas channel. Light oil and heavy oil can be recovered in different grades at different temperatures. The condensation system generally adopts a multi-stage cooling method to improve the recovery rate of fuel oil.

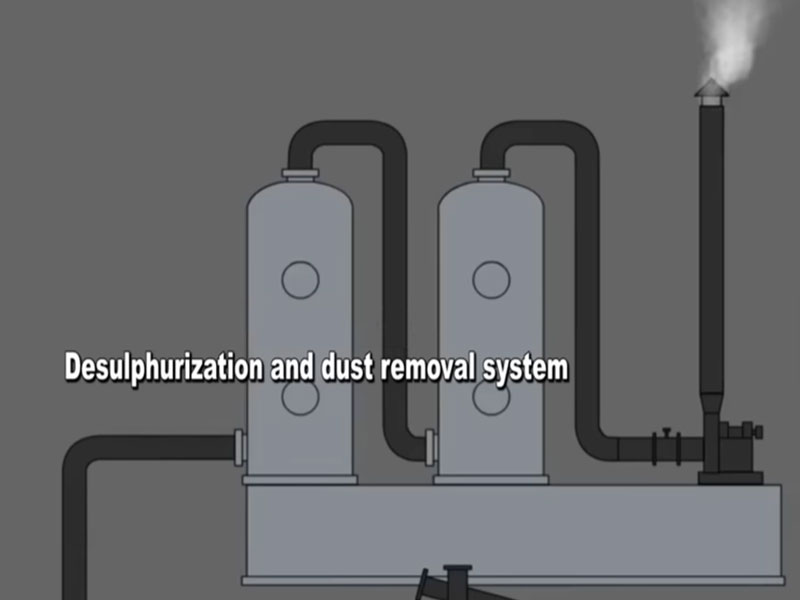

The non-condensable gas is collected into the storage tank by the gas recovery device. It is supplied to the burner of the heating system as fuel. The flue gas generated by the burner in the heating system is purified by the desulfurization and denitrification device. Finally, it is discharged after meeting the environmental protection requirements of gas emission.

Carbon black is the main solid product of pyrolysis, with a content of about 30-40%. The original pyrolysis carbon black is in powder or block form and contains impurities (such as ash, a small amount of steel wire, and heavy metals). The crude carbon black directly produced is generally used as a fuel substitute and has a lower market price. The refined and ground carbon black can be reused as a reinforcing agent and filler for rubber products such as tires and conveyor belts.

Continuous Waste Tire Pyrolysis Plant

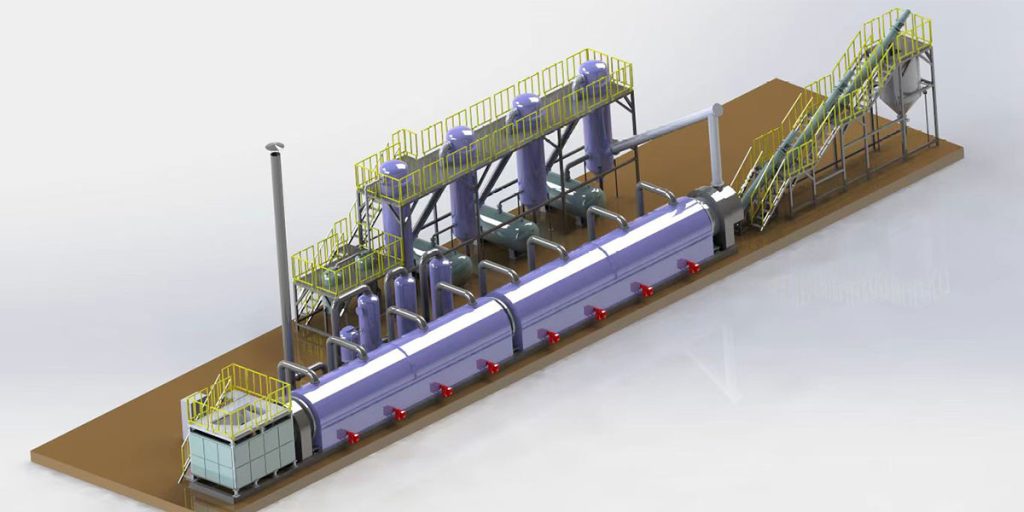

As the core support of tire rubber pyrolysis process, the pyrolysis plant plays a vital role in realizing the resource utilization of waste tires.

The industrial continuous waste tire pyrolysis production line has become the first choice for large-scale treatment of waste tires. Because continuous pyrolysis plant has excellent continuous production capacity and efficient and stable operating performance. It realizes the industrial continuous operation of pyrolysis equipment under the premise of safety and environmental protection through the organic integration of a series of advanced technologies.

In the feeding system, waste tire blocks can be quantitatively and continuously transported to the pyrolyzer to ensure the continuity of production.

The pyrolysis system fully completes the pyrolysis reaction of the material under the conditions of slight negative pressure, set temperature, oxygen-free or oxygen-deficient.

The oil and gas cooling system cools and separates the oil and gas obtained by pyrolysis. The cracking oil is pumped to the tank area, and the non-condensable combustible gas enters the subsequent purification system.

Under the action of the pressure control device, the purification system purifies and stabilizes the non-condensable combustible gas. Then it is transported to the continuous heating device for combustion to provide continuous heat for the pyrolysis of waste tires.

The discharging system cools and magnetically separates the solid products obtained by pyrolysis, and successfully obtains steel wire and carbon black.

The entire tire rubber pyrolysis process does not produce waste water, waste gas, or waste residue, realizing the recycling of waste tire.