Mingjie Group provides pyrolysis plant and pyrolysis oil distillation plant as the primary equipment for the Tyre to Diesel Recycling Plant. These facilities offer an innovative solution to the waste tire problem. The pyrolysis plant can convert waste tyres into pyrolysis oil, and pyrolysis oil distillation plant can can further separate and purify pyrolysis oil into more valuable fractions, such as light fuel oil and diesel fractions.

The Tyre to Diesel Recycling Plant offers significant advantages and value, encompassing key areas, such as environmental protection, resource utilization, and economics. Our pyrolysis equipment and distillation equipment have been used in waste tire to diesel projects in many countries, such as Iraq, South Korea, Malaysia, Peru, etc.

Development of Waste Tyre to Diesel Recycling Plant

While there are no exact statistics on the number of tire-to-diesel recycling plants worldwide, market trends indicate a steady growth. These Tyre to Diesel Recycling Plants are widely distributed across continents, with a high concentration in Europe, North America, and Asia.

Tyre Pyrolysis Recycling Plant in Europe

Europe has long been a global leader in the pyrolysis recycling of waste tires, with a well-developed environmental protection regulatory and policy support system. This has enabled the rapid development of tire to diesel recycling plant in Europe.

According to reports, Wastefront, an investment company of International Airlines Group (IAG), is building a massive tire pyrolysis recycling plant in Sunderland, northeast England.

The tire recycling plant uses advanced pyrolysis technology to convert waste tires into tire derived oil (TDO), which is further refined into sustainable aviation fuel (SAF). This is crucial for reducing carbon emissions from the aviation industry and promoting the development of green aviation.

The tire to oil pyrolysis plant is expected to begin operations in 2026 and will process up to 10 million waste tires annually. This tyre pyrolysis project will not only effectively address the UK’s massive waste tire disposal problem but also provide strong support for the sustainable aviation fuel market.

Tire to Oil Pyrolysis Plant in North America

The United States and Canada in North America also boast numerous tire pyrolysis recycling plants.

Some large-scale tire recycling companies in the United States have established numerous large-scale pyrolysis recycling plants, achieving efficient recycling and conversion of waste tires.

Every step in the conversion process from waste tires to diesel is closely linked. Through a series of scientifically sound processes, including pyrolysis and separation, the Tyre to Diesel Recycling Plant successfully separates and transforms the various components in waste tires.

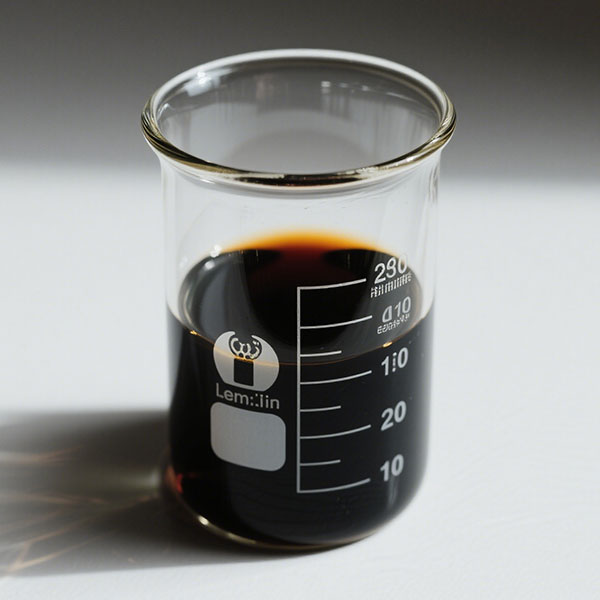

After cooling, the hydrocarbon gas produced by pyrolysis partially liquefies into tire-derived oil (TDO). TDO, a black, viscous liquid similar to crude oil, is rich in various hydrocarbons and is a high-quality feedstock for diesel production.

The synthesis gas is fed back into the reactor and burned to provide the heat needed for the pyrolysis process. This energy recycling method improves energy efficiency and reduces production costs. It also reduces dependence on external energy sources, achieving energy conservation and emission reductions throughout the entire recycling process.

Tyre Pyrolysis Plant in Asia

As one of the world’s largest tire producers and consumers, China generates a massive amount of scrap tires annually, creating an urgent need for recycling.

Currently, China has established a number of tire recycling plants of considerable scale and technology, located in regions with concentrated tire industries, such as Shandong, Henan, Jiangsu, and Zhejiang.

The tyre pyrolysis plant not only consumes a large amount of locally generated scrap tires but also improves the quality and yield of diesel and other recycled products. It has made significant contributions to resource recycling and environmental protection in China.

India and Japan are also actively developing tyre to diesel recycling plant, continuously improving the technology and scale of tire recycling.

Advantages of Tire to Diesel Recycling Plant

The Tyre to Diesel Recycling Plant effectively reduces environmental pollution from waste tires. Research indicates that a tyre recycling plant with an annual processing capacity of 500,000 waste tires can reduce the risk of land occupation by approximately 100,000 square meters annually. This significantly alleviates the problem of limited land resources. In addition, pyrolysis machine and distillation equipment can convert waste tires into diesel, reducing reliance on traditional fossil energy sources and thus lowering carbon emissions.

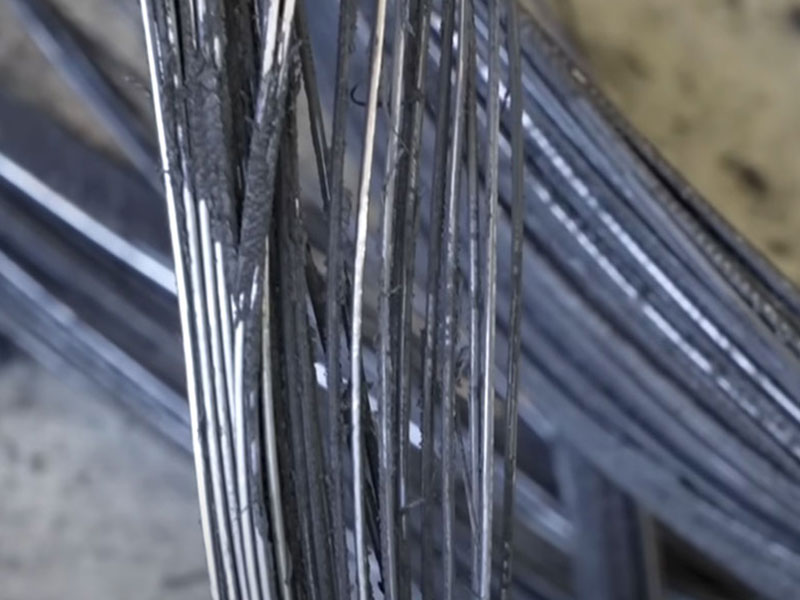

The Tyre to Diesel Recycling Plant achieves efficient resource recycling. Statistics show that for every ton of scrap tires recycled, approximately 0.2 tons of steel wire and 0.3 tons of carbon black are recovered. The reuse of these recycled materials effectively reduces the exploitation of natural resources and improves resource efficiency. Scrap tires contain a variety of recyclable components, which are fully separated and reused through the pyrolysis plant. For example, the carbon black produced during the tire pyrolysis process can be reused in the production of rubber products, improving their wear resistance and strength. The separated steel wire can also be returned to steel production, achieving a truly circular resource cycle.

The Tyre to Diesel Recycling Plant reduces dependence on traditional oil resources. Converting waste tires into diesel provides a new energy source, alleviating energy shortages to a certain extent. This not only helps ensure national energy security but also mitigates the economic impact of oil price fluctuations. The operation of the tire recycling plant creates business opportunities for related companies. From the collection and transportation of waste tires to the construction and operation of the tire pyrolysis plant, and then to the sale of diesel and other recycled products, a complete industrial chain has been formed.