On March 26, 2025, Mingjie Group completed the shipment of MJZ-20 used oil distillation plant for sale to Malaysia. The processing capacity of pyrolysis oil of MJZ-20 waste oil distillation plant is 20T/D. The following are the shipment pictures of the waste oil distillation equipment at Mingjie’s factory.

The large amount of impurities in waste oil will accelerate equipment wear and corrosion. The waste acid and heavy metals, such as lead and mercury, are extremely harmful to human health and can cause anemia, nausea, and affect the nervous system. At the same time, 500g of waste oil can pollute 1000t of clean water, and its pollution cannot be ignored. Waste oil distillation plants provide an effective solution to this waste oil treatment problem.

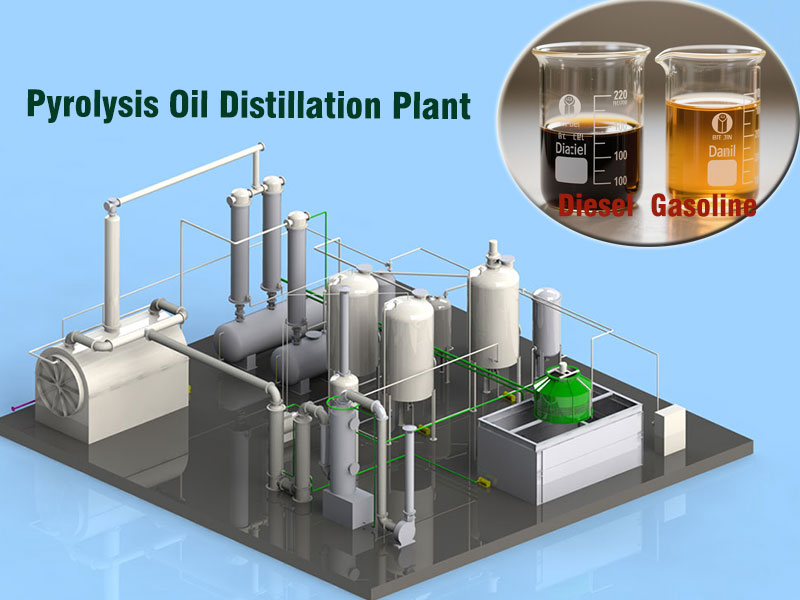

Used oil distillation plant for sale can process waste engine oil, pyrolysis oil, used transformer oil, waste lubricating oil and other industrial waste oils. So, it is also called Waste Oil Distillation Plant, Pyrolysis Oil Distillation Plant.

Core Equipment of Distillation Plant

Distillation Reactor

Distillation reactor is one of the core equipment for used oil distillation plant. Its material and structure have an important influence on the distillation effect. Different materials have different corrosion resistance, high temperature resistance and strength.

For example, when dealing with some highly corrosive waste oil, the use of 316 stainless steel distillation reactor can effectively extend the service life of the equipment.

The structural design of the distillation reactor is also crucial. Reasonable internal structure can make the waste oil heated evenly during the heating process and improve the distillation efficiency.

Condenser

The condenser is used to cool the oil and gas generated during the distillation process into liquid. The horizontal condenser has a simple structure and good cooling effect, which is suitable for waste oil distillation plants of general size.

Filter Device

The filter device is indispensable in the waste oil distillation plant. Its function is to further remove solid impurities in the oil and ensure the quality of the finished oil. The filter press achieves the purpose of removing impurities by squeezing the oil.

How Used Oil Distillation Plant Works?

MJZ-20 used oil distillation plant adopts batch distillation method, and the production process is relatively discontinuous. It needs to be shut down to process raw materials and output. However, it is highly flexible and can process a wide range of materials. It is more suitable for some small batches and diversified waste oil treatment needs. For example, distillation plant can process pyrolysis oil produced by batch pyrolysis equipment to treat solid waste (medical waste, tires, plastics, aluminum plastic waste, oil sludge, tar residue).

Vacuum Distillation

Mingjie used oil distillation plant adopts vacuum distillation technology, which is to distill under conditions below normal pressure. By reducing the pressure, the boiling point of each component in the waste oil is also reduced. In this way, the components can be separated at a relatively low temperature. Thereby reducing the decomposition of high-boiling point components and improving product quality and yield.

Waste Oil Refining Process

The refining process uses the sulfuric acid-white clay process. The strong oxidizing property of concentrated sulfuric acid is used to remove organic impurities in waste oil. Concentrated sulfuric acid reacts with unsaturated hydrocarbons, colloids, and asphaltene in waste oil. It is converted into separable substances.

After that, activated white clay is used for adsorption. Activated white clay has a huge specific surface area and can effectively adsorb pigments, residual sulfuric acid and other fine impurities in oil products. Thus, the purpose of refining oil products is achieved.

Distillation Plant for Environmental Protection

The used oil distillation plant has great environmental significance. It recycles and treats waste oil, greatly reducing the pollution caused by direct discharge of waste oil into the environment. Through the centralized treatment of used oil distillation plant, the spread of this pollution is effectively curbed.

During the treatment process, the pyrolysis oil distillation plant is equipped with complete environmental protection equipment. It can ensure that the entire treatment process meets environmental protection standards and no three wastes (waste gas, waste water, and waste residue) are generated.

In terms of waste gas treatment, for non-condensable gases, they are burned through tail gas burners before being discharged. Harmful substances are decomposed during the combustion process, reducing pollution to the atmosphere.

In terms of wastewater treatment, the small amount of wastewater generated during the distillation process can meet the emission standards after being treated by a special sewage treatment system, and can be recycled or safely discharged.

In terms of waste residue treatment, for the small amount of acid residue, white clay residue generated. Recycling or safe landfill in a reasonable way avoids pollution to soil and water bodies.