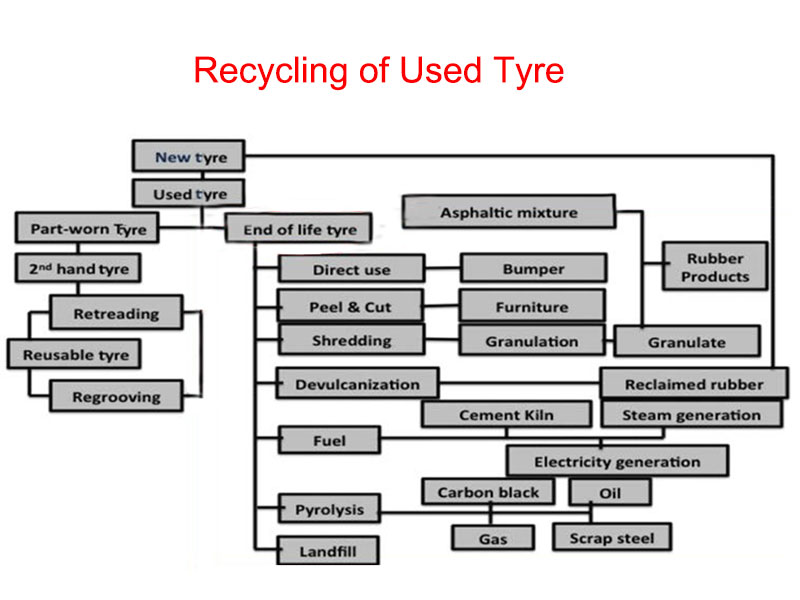

Faced with many problems brought by waste tires, people have been exploring various used tire disposal methods. In the past, some traditional used tire disposal methods have been formed, such as refurbishment, crushing, and thermal energy utilization. These methods have alleviated the waste tire disposal pressure to a certain extent, but they also have some advantages and disadvantages.

If the waste tires are only worn on the tread, they can be refurbished. If the tires cannot be refurbished or scrapped, they can be recycled in the following forms, from waste tires to various terminal products.

Direct Use

Used tires can be used directly as a bumper without further crushing or processing. The direct use of used tire disposal is commonly used in noise barriers, embankments, erosion barriers, coastal protection, artificial reefs, avalanche shelters, slope stabilization, thermal insulation and landfill construction operations.

Under the concept of creative recycling, used tires have become a creative and artistic raw material, adding many unique colors to people’s lives.

Nowadays, more and more creative people transform used tire disposal into various unique art decorations, such as cute elephants, majestic lions, etc. These sculptures are not only realistic, but also cleverly use the shape and color of tires, giving people a strong visual impact.

In addition to art decorations, waste tires can also be transformed into practical and beautiful furniture. In daily life, sofa chairs, coffee tables, stools and other furniture made of tires are becoming more and more common. These furniture not only have unique shapes, but also have good stability and durability.

Tire Crushing Processing

Whole tires are mechanically crushed. Depending on the used tire disposal application, the tire fragments can be between 25-300 mm in size. Tire granules can be used for sidewalks, roads, railways, landfill construction.

Through specific used tire disposal, used tires are crushed into rubber particles of different sizes. Although these rubber particles seem small, they have a wide range of uses.

In the field of sports facility construction, they are important raw materials for paving runways. Rubber particles are mixed with adhesives and laid on the base ground. After compaction and other treatments, a plastic runway with good elasticity and anti-slip properties is formed. They can provide athletes with a good sports experience and effectively reduce the risk of sports injuries.

In some school playgrounds, gymnasiums, and professional track and field stadiums, such runways paved with rubber particles can often be seen. Rubber particles are also used to make rubber floor tiles for paving sidewalks, parking lots, children’s playgrounds and other places. It not only has the advantages of anti-slip, wear resistance, and shock absorption, but also plays a certain decorative role.

In road construction, rubber particles can be mixed with asphalt to make rubber asphalt for paving roads. Rubber asphalt can improve the flexibility, wear resistance and fatigue resistance of roads and extend the service life of roads.

Thermal Energy Utilization

Thermal energy utilization is a way as an energy resource for used tire disposal. The heat recovery principle is to use the high calorific value of waste tires to obtain heat energy through incineration, which is then used for power generation, heating.

Tire-derived fuel is widely used as energy in thermal power plants, cement kilns, steel mills, pulp and paper mills, and industrial boilers. Compared with other solid fuels, tires have a high matching energy.

In Europe, the cement industry is the main beneficiary of waste tire fuel or energy. Kilns mostly use waste tires as supplementary fuel and meet the corresponding atmospheric emission standards. The net calorific value of tires is between 26 and 34 kilocalories, which is similar to the calorific value of coal and some other common fuels.

Tires are completely burned at 650°C, producing carbon dioxide and water, as well as some inert residues such as slag and ash. The temperature inside the cement kiln reaches 1800°C, which is significantly higher than the temperature at which tires are completely burned, ensuring complete combustion.

This used tire disposal method does have a positive effect on energy acquisition. But it also has serious problems, the most prominent of which is the difficulty in controlling waste gas emissions. Waste tires contain a large amount of rubber, carbon black, steel wire and various chemical additives. During the combustion process, it will produce a large amount of harmful gases, such as sulfide, nitrogen oxides, carbon monoxide, polycyclic aromatic hydrocarbons, etc. These gases will not only have a serious impact on air quality, causing air pollution problems such as smog, but also cause harm to human health.

Pyrolysis Tire Recycling System

The pyrolysis plant is an environmentally friendly equipment in the field of used tire disposal, which can enable waste tires to achieve deep transformation. The principle of pyrolysis technology is to continuously heat waste tires under special environmental conditions without oxygen or hypoxia. Waste tires undergo a series of complex physical and chemical changes at high temperatures, and eventually decompose into a variety of valuable products such as oil and gas, carbon black and steel wire.

In the continuous tire pyrolysis process, the waste tires must first be pre-treated, such as cutting and crushing, to make them into blocks or particles of appropriate size, so that the subsequent pyrolysis reaction can be more fully carried out.

The pre-treated tires are sent to the tyre pyrolysis equipment, and the pyrolysis reactor begins to heat them. The heating temperature is usually controlled between 400-500℃. In this temperature range, the rubber polymer in the tire will gradually break and decompose into small molecular hydrocarbon substances, which exist in the form of oil and gas. At the same time, the carbon black and steel wire in the tire will gradually separate.

The oil and gas produced by pyrolysis tire recycling system are transported to the condensation system through pipelines, and are collected after cooling and condensation. Pyrolysis oil from used tyres is further processed and refined to obtain fuel oil. This fuel oil can be used as industrial fuel in power plants, boilers, etc.

Carbon black separated in the rubber pyrolysis process after further refining. It can also be used in the ink industry to give the ink good color and printing properties.

The separated steel wire can be directly recycled and reused, and after processing procedures such as remelting, it can be reused in steel production.

Pyrolysis used tire disposal realizes the deep resource utilization of waste tires and maximizes the potential value of waste tires. It reduces dependence on primary resources and has significant resource conservation and environmental protection significance.