Waste Biomass can produce biochar by pyrolysis at different temperatures and heating rates. However, the yield, properties and characteristics of biochar are different. Slow pyrolysis is a biomass pyrolysis process that mainly produces charcoal. Under slow pyrolysis conditions, the charcoal yield can reach 30% to 35%. In addition to biochar, biomass pyrolysis can also produce bio-oil and syngas.

Biochar has a high carbon content and a certain pore structure. It can be used for soil improvement, carbon sequestration, environmental remediation, and as an adsorption material.

What Factors affect Biochar Production?

Biomass can be divided into two main categories: lignocellulosic biomass and non-lignocellulosic biomass. Lignocellulosic biomass is widely used for biochar production and mainly consists of cellulose, hemicellulose, and lignin.

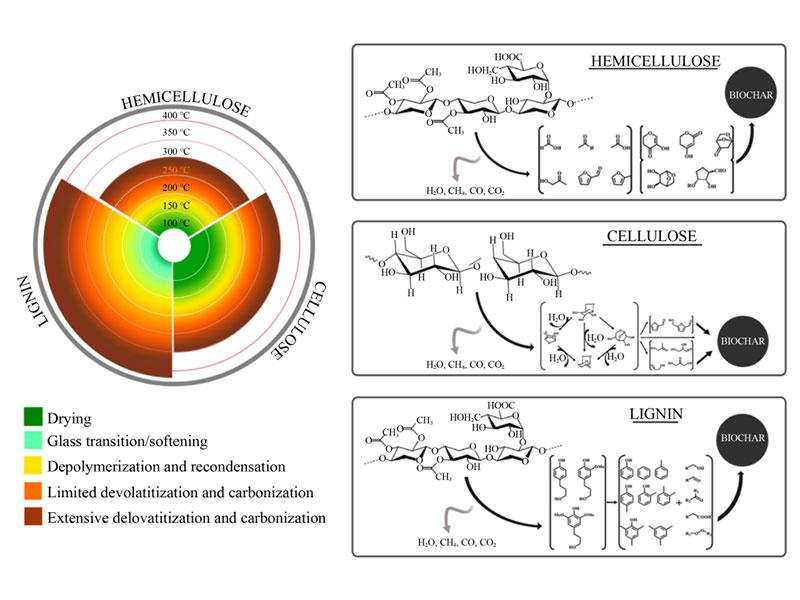

The pyrolysis behavior of lignocellulosic components (hemicellulose, cellulose, and lignin) varies due to compositional and structural differences.

Hemicellulose and cellulose are composed of simple sugar units and are easily thermally decomposed at relatively low temperatures (220–315 °C and 315–400 °C) to release volatile compounds. Lignin, due to its complex aromatic polymer structure, decomposes at higher temperatures of 350–500 °C and is the main precursor for biochar production.

Effects of Biomass Types on Biochar

The properties of biochar are affected by the biomass types. Different biomasses contain different levels of organic compounds such as lignin, cellulose, and hemicellulose. During the biomass pyrolysis process, these compounds break down and transform in different ways. This results in the conversion of biomass into biochar with unique chemical compositions.

During the pyrolysis of cellulose and hemicellulose, some volatile products and a small amount of charcoal are mainly produced. While the pyrolysis of lignin mainly produces biochar and a small amount of water.

Cellulose- and hemicellulose-rich feedstocks, such as straw, bamboo, bagasse. The biochar produced by straw charcoal making machine has lower fixed carbon content and aromaticity, but more oxygen-containing functional groups. This enhances the adsorption properties of bagasse charcoal.

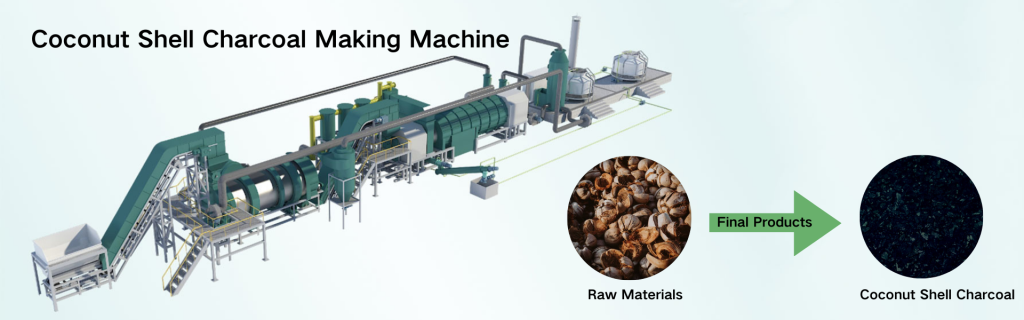

In contrast, lignin-rich biomass feedstocks, such as wood, coconut shells, palm shells. The biochar produced by coconut shell charcoal making machine has a more porous structure, higher specific surface area, aromaticity, stability, and fixed carbon content. Palm shell charcoal is suitable for soil improvement and environmental remediation.

Effects of Biomass Pyrolysis Process on Biochar

Pyrolysis Temperature

Increasing the pyrolysis temperature can increase the fixed carbon content, ash content, aromaticity, and specific surface area of biochar. At the same time, it reduces the yield, hydrogen, oxygen, and polarity. High temperature promotes the release of volatile components in biomass, leaving more fixed carbon.

In addition, high temperature increases the ash content, converting volatile minerals in biomass into ash residues. Aromaticity generally increases with increasing temperature, and complex organic compounds decompose into simpler aromatic structures.

However, too high temperature may cause excessive degradation and carbonization of biomass and reduce the hydrophobicity of biochar.

Residence Time

Residence time is closely related to carrier gas flow rate and affects the biomass carbonization and the yield and properties of biochar. Longer residence times generally ensure more complete conversion, but may increase energy consumption and cost.

Extended residence time increases the pH and ash content of biochar, but reduces its hydrogen, carbon, and nitrogen content. Specific surface area and pore volume increase with increasing residence time. However, they decrease after a certain time.

Heating Rate

The heating rate affects the properties of biochar, especially the surface area. Higher heating rates generally increase the surface area of biochar.

However, there is an optimal heating rate, above which the surface area decreases. For example, studies have shown that the specific surface area of biochar increases significantly as the heating rate increases from 10 to 40 °C·min−1.

In Summary

Studies have shown that biomass raw material selection and pyrolysis conditions have a significant impact on the properties and yield of biochar.

The selection of renewable raw materials is essential to achieve the final characteristics and performance of biochar production. At the same time, it helps to reduce dependence on limited resources and recycle waste, thereby mitigating environmental impact.

Optimizing pyrolysis parameters (such as temperature, heating rate, and residence time) can balance the yield and quality of biochar production, while reducing energy consumption and environmental impact.