The pyrolysis reactor is the core equipment for waste plastic pyrolysis to fuel oil. Pyrolysis technology can convert waste plastics into oil and gas products, which can be reused as fuel and chemical raw materials. It is a way to efficiently recycle waste plastics.

Plastic poses a threat to the environment because it is not biodegradable. But it also has the potential to become a significant resource for the production of alternative energy, creating an untapped market worth billions of dollars. Every year, millions of tons of plastic are produced worldwide, leading to a significant increase in plastic waste, which creates ecological and environmental problems.

Plastic waste can be dealt with in two ways: recycling or converting plastic into energy. It is estimated that only about 10% of waste plastic is currently recycled. Pyrolysis is a technology that heats plastic to 400-700°C in the absence of oxygen, a process that produces high calorific value fuel oil.

Pyrolysis Plastic into Energy

Pyrolysis waste plastic into energy providing an effective way to address the growing environmental and ecological problems of plastic waste. The waste plastic pyrolysis to fuel oil method reduces the impact of plastics on the environment. It is in line with global initiatives to promote sustainable waste and energy management. Plastic pyrolysis projects promote many of the United Nations’ Sustainable Development Goals, including SDG-7 (affordable and clean energy), SDG-12 (responsible consumption and production) and SDG-13 (climate action).

Plastics include many types, especially high-density polyethylene (HDPE), low-density polyethylene (LDPE), polystyrene (PS), polypropylene (PP), polyethylene terephthalate (PET) and polyvinyl chloride (PVC). They have unique properties, applications and effects in the pyrolysis process. At the same time, the widespread use of plastics provides an opportunity to use waste plastics as a source of fuel production.

Waste Plastic Pyrolysis To Fuel Oil

The pyrolysis of polystyrene (PS) is accomplished under milder conditions than the pyrolysis of high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP). Compared to PS plastics, polyethylene (HDPE and LDPE) and PP waste plastic pyrolysis to fuel oil require significantly higher temperatures.

PS pyrolysis raw material is different from PP and PE type plastics. It can be heated at low temperature, and PS pyrolysis produces less viscous oil.

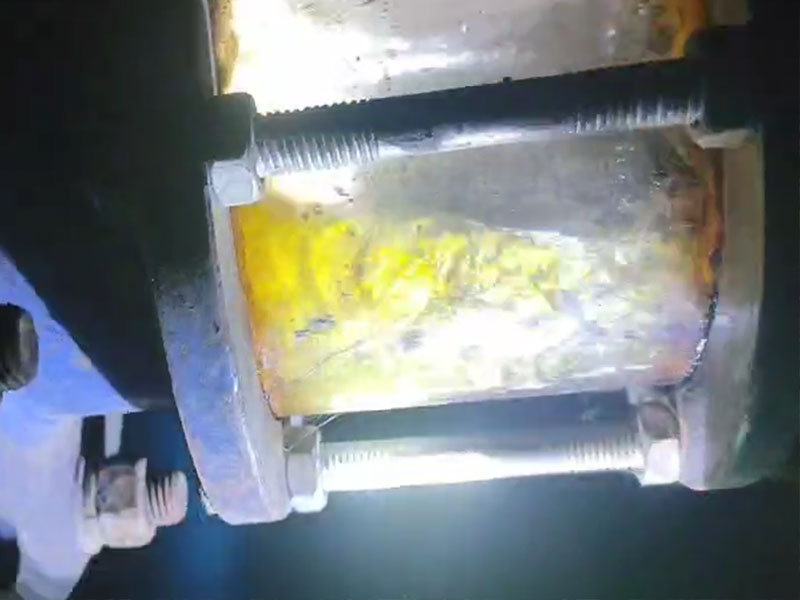

PE plastic can withstand high temperatures above 500°C due to its long chain structure. When heated and cracked, it produces wax. Our batch plastic pyrolysis plant is equipped with a dewaxing unit, which can effectively avoid pipe blockage problems during the treatment of waste plastics.

PP plastic is resistant to high temperatures, and produces liquid oil containing high aromatic compounds through pyrolysis.

Pyrolysis of PVC plastic produces dangerous chlorine gas. The presence of chlorine affects the activity of the catalyst, resulting in increased coke formation.

Effect of Temperature on Pyrolysis Fuel Oil

In the waste plastic pyrolysis to fuel oil process, temperature is the most important operating parameter in the process. It determines the carbon chain breaking reaction. Different plastics have different degradation temperature ranges depending on their molecular structure.

Common plastics such as PET, LDPE, HDPE, PS and PP have thermal degradation temperatures ranging from 250 to 360 °C.

The specific operating temperature requirements depend largely on the desired product composition. If combustible products are preferred, pyrolysis temperatures over 450 °C are recommended. Whereas lower temperature ranges of 300-500 °C are suitable for obtaining liquid pyrolysis oil.

Plastic Pyrolysis Plant

In addition to temperature, choosing the right pyrolysis plant is critical for waste plastic pyrolysis to fuel oil. Batch pyrolysis plants are often used for plastic decomposition. Because they are easy to control and can process mixed plastic waste.

Batch waste plastic pyrolysis to fuel oil plant can be equipped with automatic feeding system and water-cooled automatic slag discharging system. Thus, semi continuous pyrolysis can be achieved. At the same time, safety equipment and efficient dust removal devices ensure safety and pollution-free.

Mingjie Group is a professional pyrolysis plant manufacturer with 20 years of production and operation. We have strong R&D capabilities and equipment manufacturing capabilities.

We have been providing various equipment and solid waste treatment solutions to customers at home and abroad. Including tire pyrolysis machine, plastic pyrolysis machine, medical waste pyrolysis plant, waste oil distillation equipment and biomass pyrolysis plant.

For each set of waste plastic pyrolysis to fuel oil plant, Mingjie Group will send special technicians to guide customers to install, test the machines, and train workers.