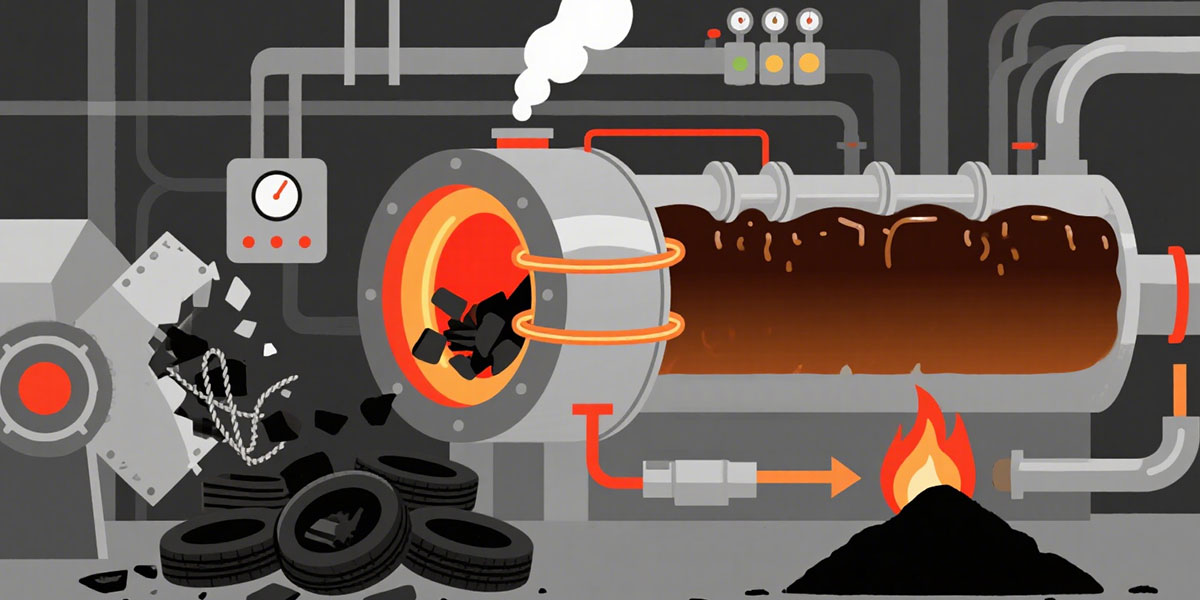

The pyrolysis plant uses pyrolysis technology to recycle waste tires. The tire pyrolysis recycling plant decomposes waste tires in an oxygen-free or oxygen-deficient high-temperature environment, converting them into fuel oil, carbon black, steel wire, and syngas.

The pyrolysis of waste tires primarily involves three processes: heating, decomposition, and products collection.

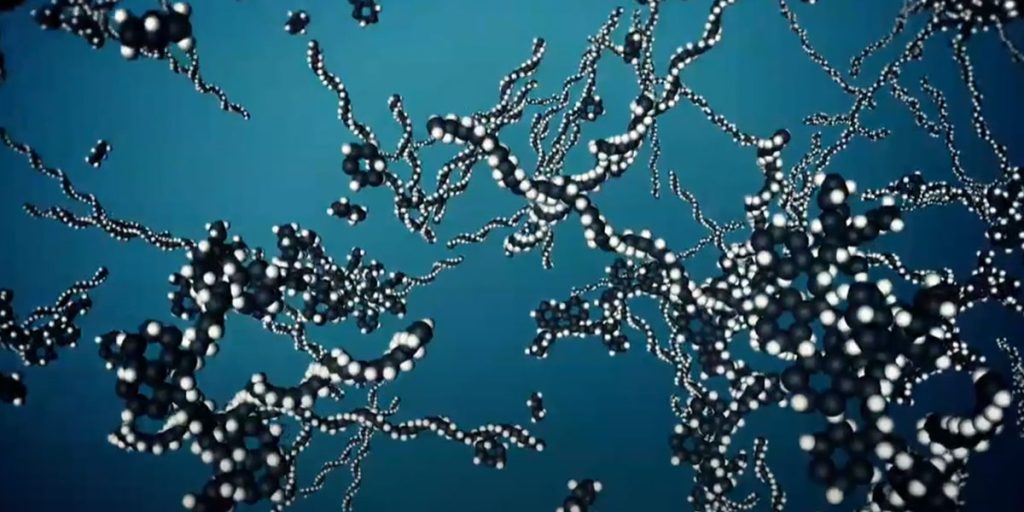

When tires are heated to 300-700°C, the chemical bonds within the rubber molecular chains break, disrupting the previously stable macromolecular structure.

During this process, the rubber component first decomposes, with the long-chain rubber hydrocarbon molecules gradually breaking down into shorter chains, producing various small-molecule compounds.

Some of these small-molecule compounds form energy-rich oil and gas, while others are converted into solid carbon black. The steel wire in the tires remains largely in its metallic form during the pyrolysis process and is ultimately separated.

Heating Process of Tire Pyrolysis Recycling

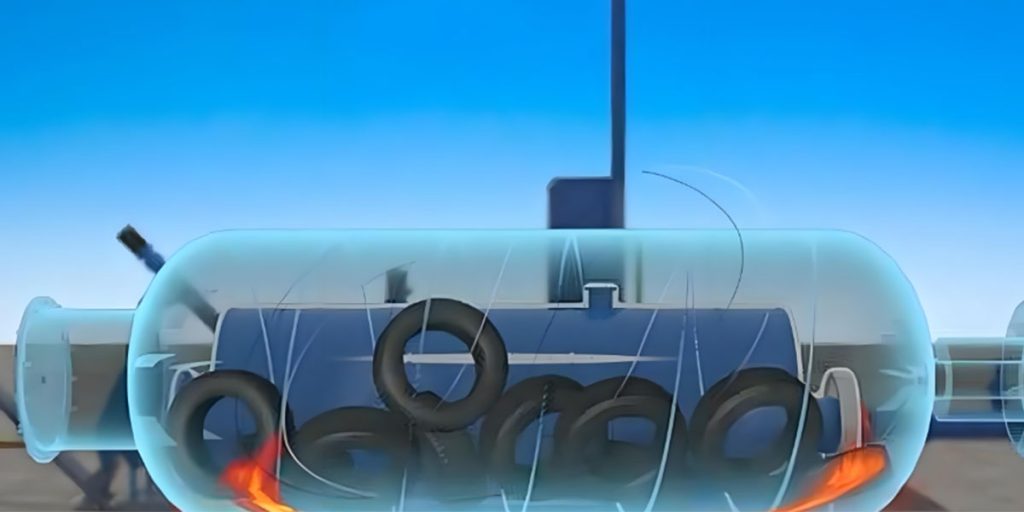

In the waste tire pyrolysis recycling process, precise control of thermal energy is crucial for ensuring an efficient and controllable reaction. Pyrolysis of waste tires requires high temperatures to provide the energy needed to break and restructure the polymer chains within them. Waste tires have a complex chemical composition, primarily consisting of natural rubber, synthetic rubber, carbon black, steel wire, and other additives. Maintaining the right heating temperature range and controlling the reaction are key to tire pyrolysis recycling.

Temperature Control

The pyrolysis temperature of scrap tires is typically controlled between 250°C and 600°C. The specific temperature range depends on the chemical composition and structural characteristics of the tire type. Different types of scrap tire rubber pyrolysis process require different temperatures.

For example, TBR (heavy truck tires) have a relatively stable molecular structure, so higher temperatures (350-420°C) are required to break down the chemical bonds within the rubber molecules. PCR (passenger car tires) and BIAS (bias-ply tires) are typically pyrolyzed between 320-380°C.

Decomposition Process

Decomposition is the core step in the thermal pyrolysis of waste tires. It is the process by which long-chain molecules in waste tires break down and form small molecular fragments. Waste tires are primarily composed of high-molecular-weight rubber, fillers, and oils. Their molecular chains are stable and have high tensile strength, making them difficult to degrade in the natural environment. During the tire pyrolysis recycling process, the chemical bonds within the rubber molecular chains break due to the action of heat, forming a series of shorter, small molecular fragments.

During the pyrolysis process of waste tires, large molecular compounds (such as rubber) in the waste tires gradually lose their stability under high temperatures. The original chemical bonds break and rearrange, forming simpler, smaller molecules. Typically, the small molecule products formed during the pyrolysis process include alkanes, alkenes, carbon black, and gases.

The pyrolysis reaction of waste tires is not a completely random chemical breakdown. It is influenced by factors such as temperature, time, and pressure. During the pyrolysis process, longer rubber molecular chains first break into medium-sized segments, which then further break into smaller molecular fragments.

The specific pyrolysis products vary depending on the type of waste tire. The cracking products of TBR and PCR are more complex, usually producing more olefins and alkanes, while BIAS and TUBE types tend to produce more gaseous products. Different molecular chain breakage patterns affect the distribution of products.

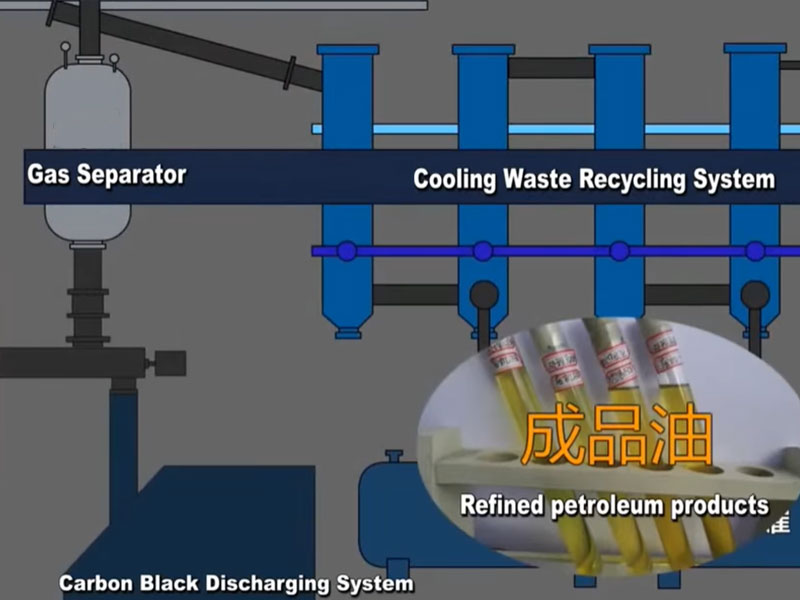

Tire Pyrolysis Product Collection

Product collection is the ultimate goal of waste tire pyrolysis technology. The main products of waste tire pyrolysis recycling include pyrolysis oil, carbon black, steel wire, and synthesis gas. These products not only have high market value but also effectively address the problem of waste tire disposal.

Waste Tire Pyrolysis Oil (TPO)

Waste tire pyrolysis oil (TPO) is an important product after waste tire pyrolysis recycling. Tire pyrolysis oil needs to be processed by the condensation system before it can be stored in the oil tank. TPO can be used as fuel or further converted into diesel and gasoline through pyrolysis oil distillation plant. Furthermore, TPO has broad application prospects in the production of plastic products. TPO recycling not only helps reduce energy consumption but also helps alleviate dependence on petroleum resources.

Carbon Black (rCB)

Recycled carbon black (rCB) is a key product after waste tire pyrolysis. The pyrolysis carbon black is collected at the carbon black outlet below the pyrolysis spiral. rCB is widely used in industries such as rubber products, coatings, and plastics. Due to its excellent electrical conductivity and material-reinforcing properties, rCB can effectively improve the mechanical properties and wear resistance of the final product. The demand for rCB in various industrial products is increasing, making it a key economic product of the waste tire pyrolysis recycling process.

Steel Wire Recycling

Through pyrolysis technology, steel wire can be effectively separated from waste tires. It can then be reprocessed into metallurgy and other industrial applications. This not only reduces steel resource consumption but also helps reduce the environmental burden of waste.

Syngas

Synthesis gas produced during the waste tire pyrolysis recycling process, such as methane, ethylene, and propylene, can be used as a heat source to power the cracking equipment. This reduces energy consumption and fossil fuel use, offering both environmental and economic benefits.