In recent years, the rapid development of the global automotive industry has led to a significant increase in the number of scrap tires. These waste tires not only pose a serious threat to the environment, but also contain a large amount of untapped resources. Waste tire recycling plant have become a key solution to this problem, playing a vital role in economic and environmental benefits.

Technology for Waste Tire Recycling Plant

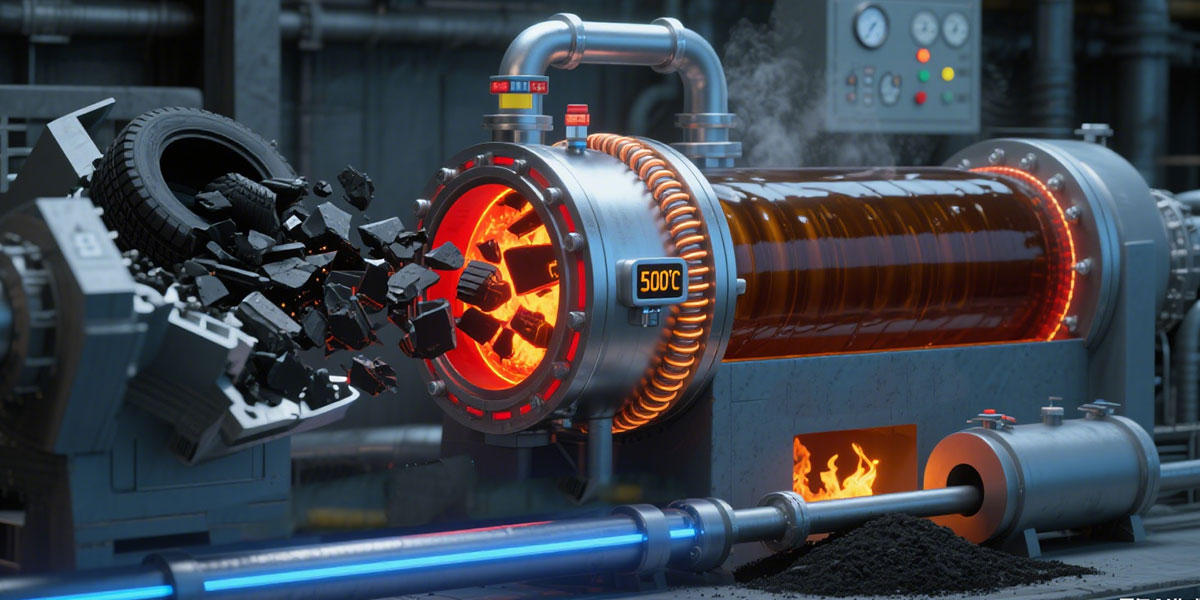

Waste Tire Pyrolysis

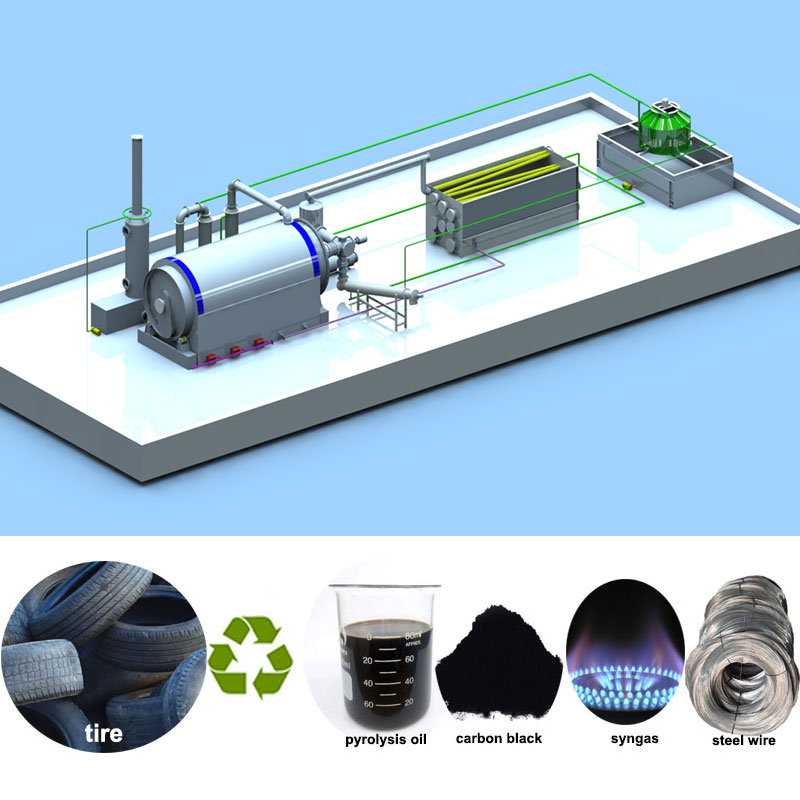

Waste tire pyrolysis has emerged as one of the most promising technologies in waste tire recycling. In a pyrolysis plant, waste tires are heated to high temperatures (typically 400 – 600°C) in the absence of oxygen. The process breaks down the complex polymers in the tires into valuable products such as pyrolysis oil, carbon black, and steel wire.

Pyrolysis oil can be used as a fuel substitute or further refined into high-quality products. Recovered carbon black is different from virgin carbon black. However, it can be used in applications such as rubber products, asphalt modification. Steel wire can be recycled and reused in the steel industry, thus completing a closed loop of material utilization.

Waste tire pyrolysis is a promising technology that offers a sustainable solution to the global waste tire management problem. It can bring both environmental and economic benefits by converting waste tires into valuable resources.

As a thermochemical process that converts waste tires into valuable products, pyrolysis technology has gradually become the focus of global attention. Pyrolysis plant can convert waste tires into pyrolysis oil (TPO), recycled carbon black (rCB), combustible gas and steel wire, realizing resource recycling. It is of great significance to alleviate resource shortages and reduce environmental pressure, and is a key link in promoting global sustainable development and building a circular economy system.

Mechanical Recycling

Mechanical recycling is a more traditional method that is widely adopted in many waste tire recycling plants. It involves shredding and grinding waste tires into rubber crumbs of various sizes. These rubber crumbs can be used for a variety of purposes, including the production of rubber-modified asphalt for road construction, sports grounds and rubber mats. The process is relatively simple and cost-effective, but it focuses mainly on the reuse of the rubber component of the tire. Compared with the pyrolysis of waste tires, other valuable materials are underutilized.

Devulcanization Technology

Desulfurization aims to break the sulfur cross-links in vulcanized rubber and restore its plasticity. This allows the rubber to be re-compounded and used in new tire production or other rubber products.

Economic Benefits of Tire Recycling Pyrolysis Plant

From an economic perspective, waste tire recycling plant offers multiple revenue streams. The sale of recycled products such as pyrolysis oil, carbon black, and rubber crumbs generates income. Additionally, some plants can also profit from government subsidies and incentives provided for environmental protection and resource recycling. Moreover, by reducing the reliance on virgin materials, waste tire recycling plants can help companies cut costs in the long run, enhancing their competitiveness in the market.

Waste tire recycling plants are at the forefront of sustainable resource management. Advanced recycling technologies not only alleviate environmental issues but also create economic opportunities.

Environmental Benefits of Waste Tyre Pyrolysis Plant

Pyrolysis tire to oil can significantly reduce the amount of waste sent to landfills. This helps conserve valuable land resources and reduce environmental issues associated with tire dumping.

Compared to traditional disposal methods such as incineration, tire pyrolysis plant produces fewer air pollutants. Incineration of scrap tires releases large amounts of sulfur dioxide, nitrogen oxides, and particulate matter, which can cause air pollution and respiratory problems. Pyrolysis can be carried out in a controlled environment with appropriate pollution control measures to minimize the emission of harmful substances.

Using pyrolysis products (pyrolysis oil and carbon black) helps reduce the overall carbon footprint. For example, pyrolysis of carbon black in tires can reduce the need to produce virgin carbon black from fossil fuels, thereby reducing CO2 emissions.