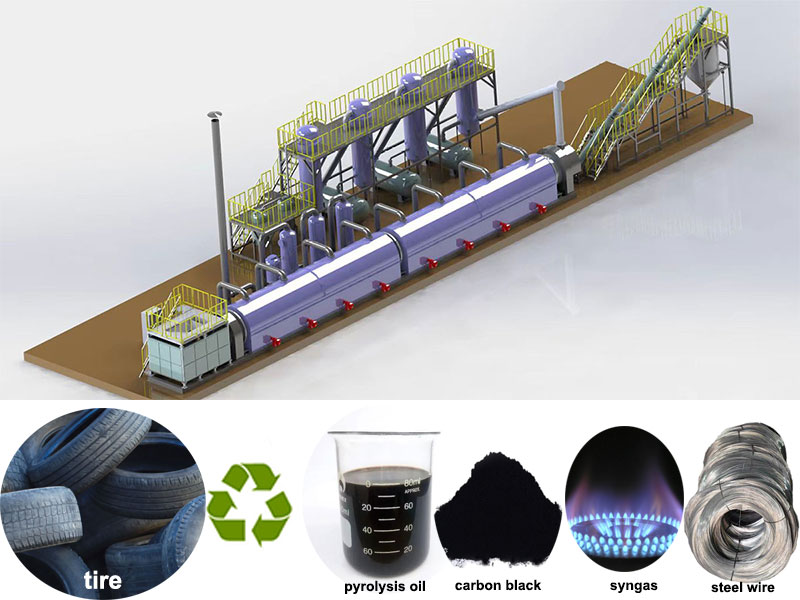

The waste tire pyrolysis is a process of converting tires by heating in an oxygen-free or oxygen-deficient environment. Ultimately, waste tires are converted into syngas, pyrolysis oil, solid carbon black, and steel wire.

The pyrolysis process of waste tires follows the principle of polymer thermal degradation kinetics. The tyre pyrolysis plant achieves efficient separation of pyrolysis products by controlling the heating rate, temperature range and residence time. The pyrolysis temperature is the core parameter that determines the yield of three-phase products (gas, liquid and solid).

Tire Pyrolysis Pyrolysis Products

Studies have shown that when the temperature is 300-400℃, liquid oil is the main output (accounting for about 40%-50%), and the main component is aromatic compounds.

At 400-500℃, the yield of gaseous products (such as hydrogen, carbon monoxide, and hydrocarbon mixtures) increases (about 30%-40%), which is suitable for recycling as fuel in the pyrolysis process.

Above 500℃, the yield of solid pyrolysis carbon black is stable (about 30%-35%), and its composition and structure are significantly affected by temperature. Carbon black has higher purity at high temperatures, which is more conducive to subsequent deep processing.

Synthetic gas: energy cycle and low-carbon fuel

The mixed gas produced by tire pyrolysis (mainly containing CH₄, C₂H₄, CO, etc.) has a calorific value of about 15-20MJ/m³. It can be directly used as a fuel for the cracking furnace to achieve energy self-sufficiency in the pyrolysis process and reduce external energy consumption. After purification, the pyrolysis gas from some waste tire pyrolysis projects can also be used as fuel to replace fossil energy coal and reduce carbon emissions.

Pyrolysis oil: high value-added industrial raw materials

The main components of tire pyrolysis oil are aromatic hydrocarbons, including benzene, toluene, xylene, etc. It is a high-quality chemical raw material that can replace coal tar for carbon black production. Pyrolysis oil can be directly used as raw material oil for carbon black devices. It can reduce dependence on traditional coal tar, reduce production costs, and promote the transformation of the carbon black industry to green raw materials. In addition, tire pyrolysis oil can be used for diesel or gasoline base oil production after waste oil distillation.

Solid products: carbon black regeneration

Pyrolytic carbon black contains residual steel wire and inorganic filler. After the metal is separated by magnetic separation, it can be processed by grinding, activation and other processes to prepare recycled carbon black (rCB). rCB can be mixed with new carbon black in a certain proportion for rubber products, or used as a filler for asphalt modification, plastic products, etc. Ultimately, pyrolytic carbon black can achieve the transformation from “black pollution” to “black gold”.

Composition of Continuous Pyrolysis Plant

Modern waste tire pyrolysis equipment is mainly based on continuous pyrolysis system, and its core components include pyrolysis reactor, feeding and slag discharging system, heating and condensing system, and emission purification treatment system.

The pyrolysis reactor adopts a horizontal rotating structure to ensure that the material is evenly heated. The built-in flow material detection technology can monitor the tire pyrolysis process in real time to avoid local overheating or blockage.

The feeding and slag discharging system adopts automatic continuous feeding and is equipped with an intelligent slag discharging device. It can shorten material processing time, reduce labor costs and improve production efficiency.

The heating and condensation system provides heat energy through indirect heating or direct combustion of pyrolysis gas. Equipped with a multi-stage condensation device, liquid oil is efficiently separated to solve the problem of easy blockage of traditional condensation pipes.

The environmental protection treatment system can adopt an integrated waste gas recovery and reuse device (combustion of pyrolysis gas for heating), dry or wet desulfurization and dust removal system (removal of H₂S, dust and other pollutants). In this way, it can ensure that emissions meet standards and reduce secondary pollution.

Tyre Recycling Pyrolysis Plant Advantage

The advantages of the fully continuous pyrolysis equipment are that it operates at normal pressure to ensure safety, and special sealing technology prevents gas leakage. The double-layer pyrolysis reactor structure extends the service life. The overall fully automatic tire pyrolysis solution achieves a balance between harmless treatment and high value-added product recovery.

Compared with traditional waste tire treatment methods (landfill, incineration), tire pyrolysis technology reduces solid waste by more than 80% from the source. The tire recycling pyrolysis plant avoids pollutants such as dioxins produced by incineration, and achieves the reduction, harmlessness and resource utilization of waste tires.

Pyrolysis products have diversified utilization, such as rCB replacing virgin carbon black and pyrolysis oil replacing fossil fuels. It reduces dependence on natural resources and reduces the carbon footprint of the rubber industry. It is estimated that tire pyrolysis of each ton of waste tires can reduce about 1.2 tons of CO₂ emissions, which is equivalent to the carbon fixation effect of planting 67 fir trees. As the core channel for high-value treatment of waste tires, pyrolysis technology will play a key role in the circular economy system.