Currently, there are two main methods for waste wind blade recycling: mechanical recycling and chemical recycling. Chemical recycling is further divided into solvent recycling and pyrolysis recycling.

Wind turbine blades are the core components that convert wind energy into electrical energy. To adapt to harsh natural conditions, reduce the weight of the blades themselves, and meet the requirements of mass production, all commercially available wind turbine blades currently use composite materials. They are mainly composed of a matrix resin, a sandwich coating, and reinforcing fibers.

Mechanical recycling involves crushing the wind turbine blades into chunks, then grinding them into different particle sizes for use in building materials. However, mechanical wind blade recycling cannot fully utilize the performance and value of the recycled reinforcing fibers. It can only be partially used as filler, resulting in poor economic efficiency.

Solvent recycling uses catalysts under heating or pressurizing conditions to break the carbon-nitrogen bonds in the thermosetting resin. It converts the resin into linear polymers which are then dissolved in organic solvents. Dissolving the epoxy resin with organic solvents yields long fibers with excellent mechanical properties. However, solvent wind blade recycling is costly and generates a large amount of waste liquid, limiting its large-scale industrial application.

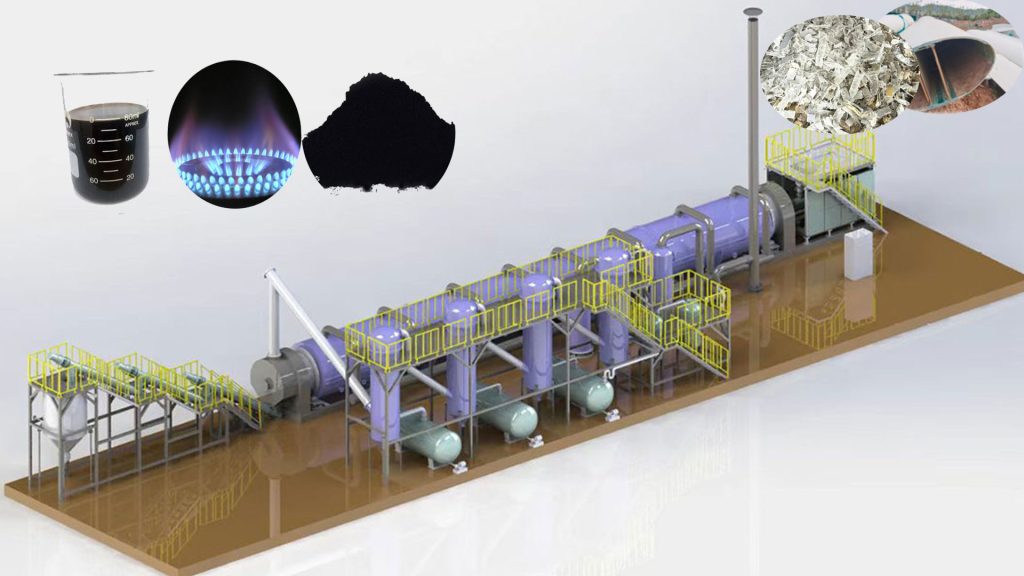

Pyrolysis for wind turbine blades recycling involves heating the wind blades in an oxygen-free environment using pyrolysis equipment. This degrades the epoxy resin in the waste blades into pyrolysis gas and pyrolysis oil, while simultaneously recovering the reinforcing fibers. Pyrolysis wind blade recycling has high processing capacity and recovery rate.

During the pyrolysis process, the polymer in the waste blades is decomposed into small molecules, forming pyrolysis oil and gas. The pyrolysis oil can be further separated and purified to obtain high-quality chemical raw materials. The glass fibers recovered through pyrolysis are intact and have good performance, with physicochemical properties essentially comparable to newly produced glass fibers.

Pyrolysis technology is relatively mature and can be widely applied in the resource utilization of waste blades.

Advantages of Pyrolysis in Waste Wind Blade Recycling

The pyrolysis method for wind blade recycling enables resource circularity. The pyrolysis plant converts the discarded wind turbine blades into pyrolysis oil, syngas, and solid residue.

Pyrolysis wind blade recycling is a leading method for fiber recovery. It has high processing capacity and recovery rates, accurately recovering reinforcing fibers from waste blades while preserving their strength to the greatest extent possible.

During the pyrolysis process, the polymers in the waste blades are cracked into smaller molecules, forming pyrolysis oil and gas. The recovered glass fibers remain intact and retain their excellent properties, allowing for their reuse.

Experiments have shown that the tensile strength retention rate of the glass fibers recovered after pyrolysis treatment is as high as over 90%. In practical applications, these recovered glass fibers are used to manufacture new composite material panels. The resulting panels exhibit excellent strength and durability, fully meeting relevant industry standards. They can be widely used in construction, automotive manufacturing, and other fields, truly achieving efficient resource recycling.

Factors Affecting the Pyrolysis of Wind Turbine Blades

In the pyrolysis waste wind turbine blade recycling process, the pyrolysis atmosphere, heating rate, and temperature are the three core process parameters that determine the final products.

Temperature conditions: The pyrolysis furnace temperature is usually controlled between 400℃ and 800℃. Different temperatures directly affect the distribution and quality of pyrolysis products. Too high or too low temperatures will reduce the fiber recovery rate or the quality of the pyrolysis oil.

Pyrolysis time: Generally, around 5 hours is the optimal duration. Inappropriate duration will affect the purity and tensile strength of the recovered glass fibers.

Reaction environment: A strictly oxygen-free or oxygen-deficient environment must be maintained. Otherwise, it will affect the degradation efficiency of organic components and may also damage the performance of the reinforcing fibers.