Plastic pyrolysis plant can convert waste plastics into pyrolysis oil, carbon black and syngas by pyrolysis technology. Waste plastics are a common environmental pollutant. It can process most waste plastics, such as PP, PE, PS, ABS or mixed plastics, except for PVC and PET.

Pyrolysis Plastic Recycling

The excessive use of plastic products is often accompanied by the generation of a large amount of plastic solid waste (PSW), which poses a serious threat to the ecological environment. Every year, more than 60% of PSW enters landfills or is directly discharged into the environment. Therefore, plastic pollution control is imminent. Considering that plastics come from fossil fuels with high calorific value, pyrolysis technology of waste plastics has become a wise move to optimize the energy structure.

Plastic Waste Pyrolysis Project

As global plastic production increases, the problem of waste plastic disposal is becoming increasingly serious. Pyrolysis plastic recycling projects have attracted widespread attention as a method to convert waste plastics into high-value-added products - fuel oil, syngas and carbon black. Waste plastic pyrolysis machine is an effective solution for "white pollution". Pyrolysis plant can process waste plastics from household solid waste, medical waste, and marine debris.

Contact Us To Get Plastic Recycling Pyrolysis Solution

As a professional pyrolysis plant manufacturer, Mingjie Group can provide effective solutions to reduce environmental pollution and recover resources.

Plastic Recycling Pyrolysis Plant Application

Mingjie plastic pyrolysis machine has been applied to plastic recycling projects in multiple countries, including Vietnam, the Philippines, Morocco, Pakistan, Poland, Uzbekistan, Thailand, and Romania. Plastic pyrolysis equipment is used to process various low-value, contaminated mixed plastics that are difficult to recycle mechanically. It successfully converts plastics into pyrolysis oil, syngas and carbon black.

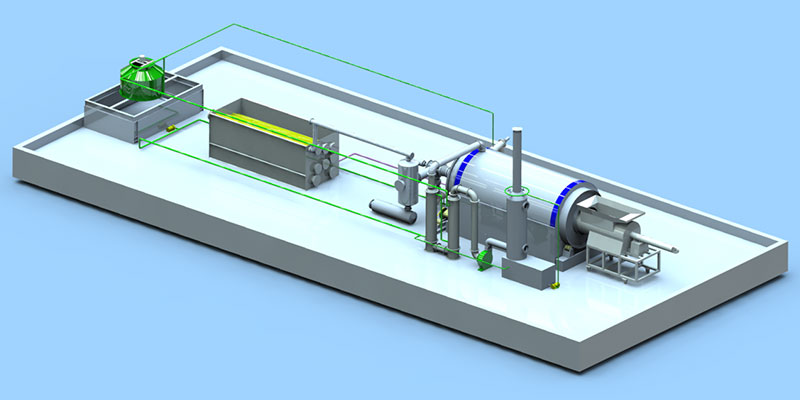

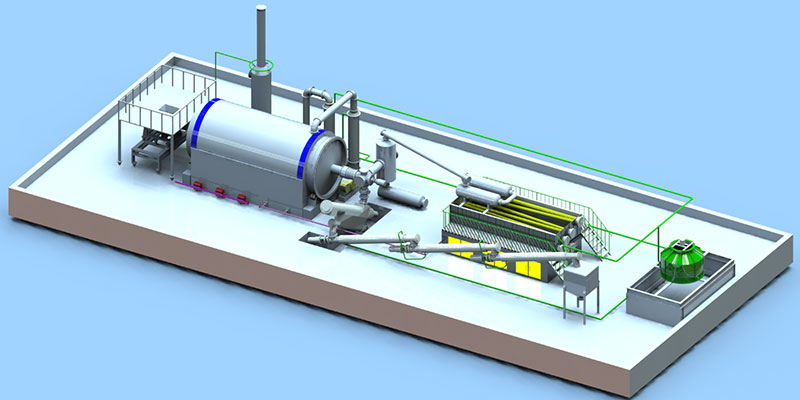

Plastic Pyrolysis Plant for Sale

Plastic pyrolysis plant for sale is divided into continuous pyrolysis equipment, semi-continuous pyrolysis plant, batch pyrolysis equipment and small pyrolysis plant. Continuous plastic pyrolysis equipment can realize automatic and continuous feeding and slag discharge. Batch plastic pyrolysis machine requires manual operation to realize feeding and slag discharge. The pyrolysis plant is equipped with safety equipment and efficient dust removal devices, which can ensure the safety and pollution-free process of plastic pyrolysis.

Small Pyrolysis Plant

- Skid-mounted design: The pyrolysis reactor, feeding system, condensation separation, tail gas treatment, and control system are integrated in a standard container.

- Compact and flexible: The small pyrolysis machine has a small footprint and is suitable for small-scale pyrolysis. It can process 1-2T/D waste tires.

- Quick installation: After the small pyrolysis machine is transported to the site, it only needs simple installation and commissioning.

Batch Pyrolysis Plant

- Can be loaded with whole tyres or packed plastic bale, without shredding.

- Capacity of 6-15T/D, which is suitable for small-scale or medium-scale production.

- Low investment cost and high slag discharge efficiency.

- Equipped with dewaxing device to effectively avoid pipe clogging problems during plastic processing.

Semi Continuous Pyrolysis Plant

- Feeding size shall be 5-8mm rubber granule, tyre shall be shredded and steel wire will be removed.

- Processong capacity 15-16T/D tyre, 12T/D plastic.

- Equipped with auto feeder system, feeding can be done at high temperature.

- From feeding to discharging, the whole press is sealed, operation environment is clean.

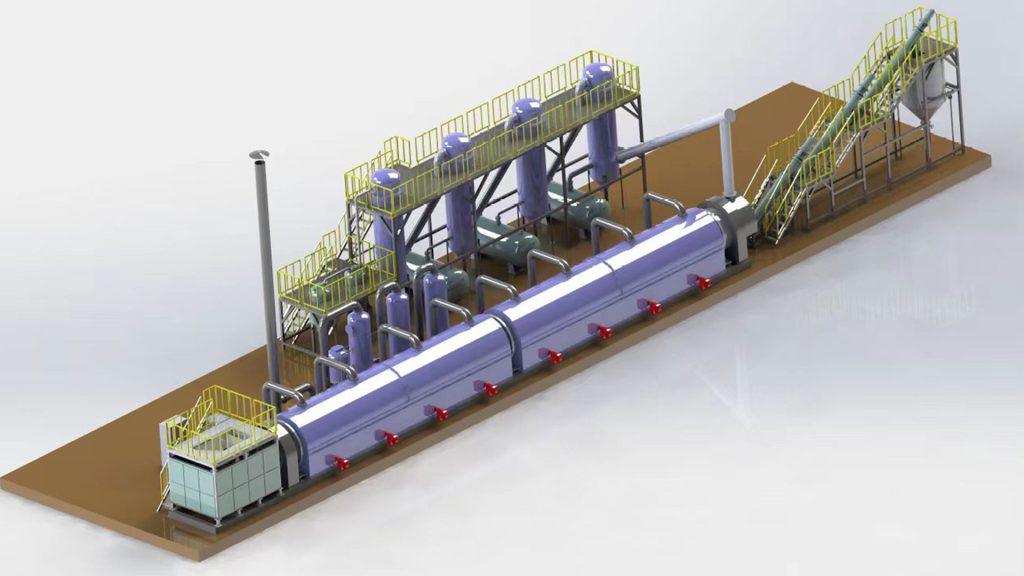

Fully Automatic Pyrolysis Plant

- Feeding size shall be 5-8mm rubber granule, tyre shall be shredded and steel wire will be removed.

- Processong capacity 35-40T/D tyre, 30T/D plastic.

- Fully continuous feeding and discharging in 24hours.

- From feeding to discharging, the whole press is sealed, operation environment is clean.

| Model | Capacity | Reactor Size | Operation |

| MJ-2 | 2T/D | D1400*L4000mm | Skid Mounted Batch Type |

| MJ-6 | 6T/D | D2200*L6000mm | Batch Type |

| MJ-10 | 10T/D | D2600*L6600mm | Batch Type |

| MJ-12 | 12T/D | D2800*L7100mm | Batch Type |

| MJ-15 | 15T/D | D2800*L8000mm | Batch Type |

| MJL-15 | 15-16T/D | D2800*L7100mm | Semi-continuous Type |

| MLL-20P | 25-30T/D | D1600*L26000mm | Fully continuous Type |

| MLL-30T | 35-40T/D | D1600*L26000mm | Fully continuous Type |

| Applicable fuel | Coal/natural gas/LPG/ Diesel/wood/pyrolysis oil | ||

| Thickness of Reactor | 16mm/18mm | ||

| Cooling method | Water Cooling | ||

| Land Required | 300-400m2 | ||

| Operating Pressure | Constant pressure | ||

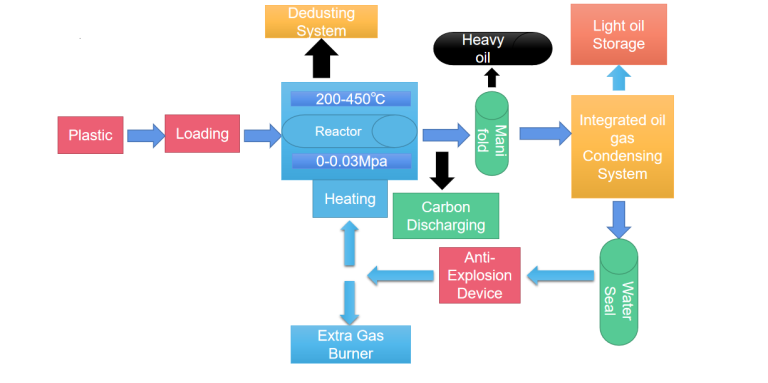

Plastic Waste Pyrolysis Process

The pyrolysis process of waste plastics is simple and convenient. Pyrolysis plant can not only solve the problem of plastic waste disposal, but also produce renewable resources.

- Pretreatment: Waste plastics are first pretreated, including sorting, crushing, washing and drying. This removes impurities (including PVC and PET plastics) and moisture.

- High-temperature pyrolysis: The pretreated waste plastics are fed into a pyrolysis reactor. Under high temperature (450-650°C) and oxygen-deficient conditions, the pyrolysis system decomposes the waste plastics into small molecular gases, liquids and solid residues.

- Condensation: The gases and liquids produced by pyrolysis are condensed through a condenser to form liquid fuel oil.

- Separation: The condensed fuel oil contains components with different boiling points. At this time, they need to be separated through distillation equipment to obtain light gasoline, diesel and heavy fuel oil.

- Tail gas treatment: The tail gas produced by pyrolysis contains harmful substances such as dioxins, benzene and carbon monoxide. These harmful substances need to be removed through tail gas treatment systems, such as activated carbon adsorption, catalytic combustion or wet scrubbing.

- Solid residue treatment: The solid residue produced by thermal cracking is mainly carbon black, which can be used as fuel or other industrial raw materials.

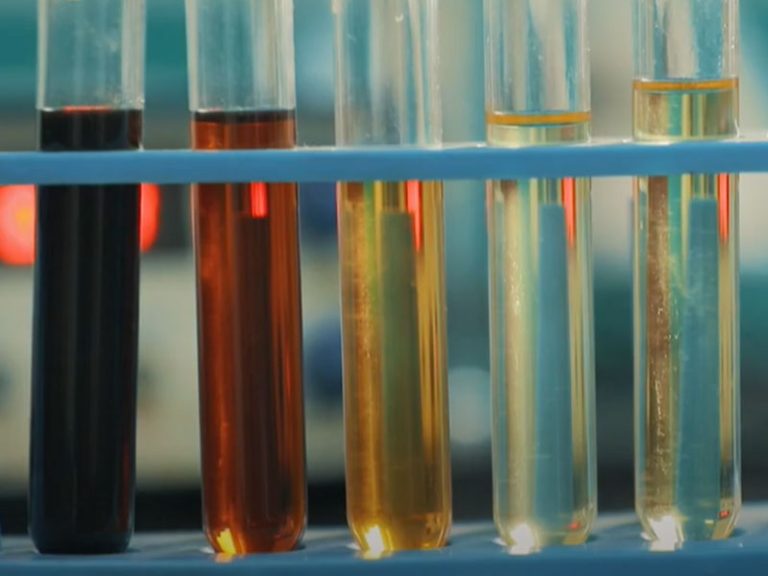

Plastic Pyrolysis Oil To Diesel Process

The process of making diesel from plastic pyrolysis oil through waste oil distillation equipment usually includes the following steps.

Plastic Pyrolysis Oil Pretreatment

Separation of impurities: Use gravity sedimentation method to remove impurities such as solid particles and water to obtain relatively pure pyrolysis oil.

Distillation Separation

Heating: The pretreated pyrolysis oil is sent to the distillation tower and heated by the heating system. The heating method can be thermal oil heating, steam heating or direct combustion heating. The pyrolysis oil gradually heats up to the boiling point in the distillation tower and begins to vaporize.

Fractionation: Different temperature zones are formed in the distillation tower according to the different boiling points of the components in the pyrolysis oil. Low-boiling components such as gasoline fractions will be separated first in the upper part of the distillation tower. The diesel fraction is separated in the appropriate temperature zone and rises to a specific position of the distillation tower in the form of steam.

Condensation: The diesel fraction steam separated from the distillation tower enters the condenser. The steam is cooled and liquefied by heat exchange with cooling water or other cooling media to form liquid diesel.

Refining

The liquefied diesel is collected in a special storage tank as a preliminary diesel product. The preliminary diesel may still contain some impurities or undesirable components and need to be further refined. If the acid content in the pyrolysis oil is high, neutralization treatment is required to reduce corrosion to subsequent equipment.

Filtering

The pyrolysis oil is passed through the filter to further remove fine solid particles and impurities. This ensures that the pyrolysis oil entering the distillation equipment has a high purity.

Why Can't Plastic Pyrolysis Equipment Process PVC and PET materials?

Because PVC and PET will corrode the plastic pyrolysis machine, pollute the environment, and reduce economic benefits.

PVC is a chlorine-containing plastic that releases a large amount of hydrogen chloride during pyrolysis. Hydrogen chloride is a toxic gas that can cause serious harm to pyrolysis plants, human health and the environment. In addition, PVC will produce harmful substances (such as dioxins and furans) during pyrolysis, which are carcinogenic and persistent.

PET is a thermoplastic polyester that releases a large amount of ethylene glycol during pyrolysis. Ethylene glycol is a toxic substance that is harmful to human health and the environment. In addition, PET will produce harmful substances (such as terephthalic acid and carbon monoxide) during pyrolysis. The release of these substances will pollute the atmospheric environment and affect human health.

CONTACT US

Please Feel free to give your inquiry in the form below, and we will reply you in 24 hours.