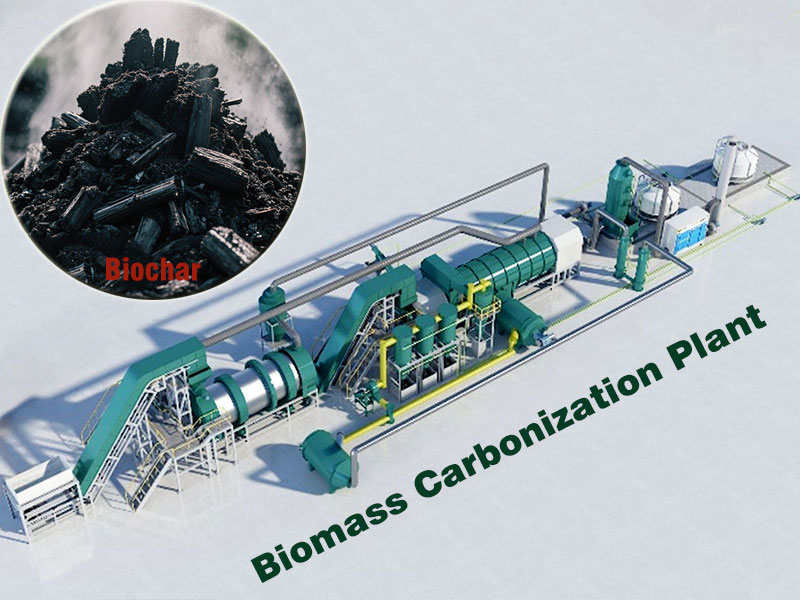

Biochar production equipment is increasingly used in agriculture, environmental protection, energy and other fields. The working process of Mingjie fully continuous biomass carbonization plant includes the pretreatment of raw materials, precise control of the biomass pyrolysis process, collection of biochar products, and exhaust gas purification.

In agriculture, biochar is used as a soil conditioner to help improve soil fertility and crop yields. In environmental protection, it is used for carbon sequestration and pollution control. In the energy field, it can be used as a fuel or part of energy storage materials.

The wide application of Biochar has led to a continuous increase in demand for biochar production equipment. Without advanced and efficient Biochar Production Equipment, it is difficult to achieve large-scale, high-quality production of Biochar. The performance of the biomass pyrolysis plant directly determines the output, quality and production cost of Biochar.

How is Biochar Produced?

Biochar is a solid material rich in carbon, which is converted from waste biomass through a pyrolysis process. Common biomass raw materials include agricultural waste (straw, chicken manure, pig manure), wood, industrial organic waste or urban sludge.

Biomass waste is put into the biochar production equipment, which is heated at a high temperature of 300-800°C without the participation of oxygen. During the pyrolysis process, the water and volatile substances in the biomass are gradually removed. Finally, a black biochar is discharged from the slag system.

Continuous Biochar Production Equipment

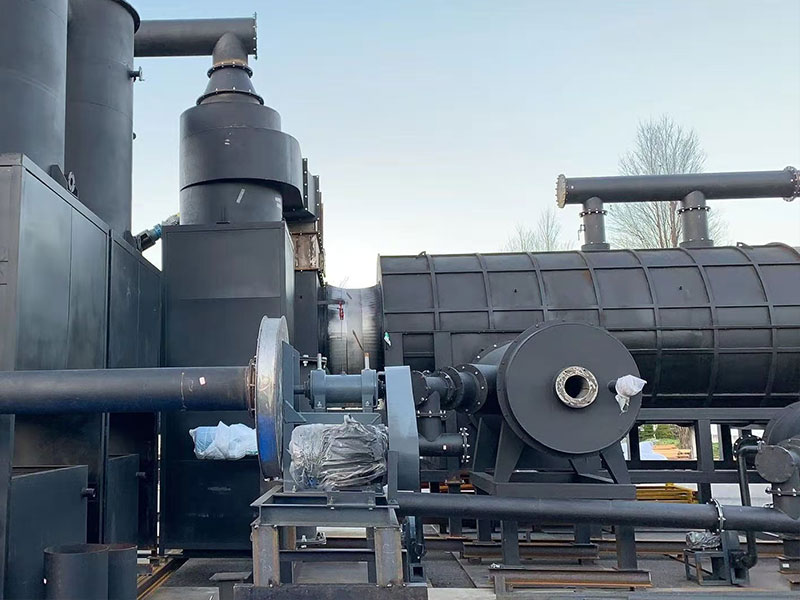

The continuous biomass carbonization plant is one of the advanced biochar production equipment in the world. It adopts a fully sealed stainless steel pyrolysis reactor structure. It is equipped with feeding system, discharging system, heating system, gas emission purification system and collection unit.

The working principle of the pyrolysis reactor is to use high temperature in an oxygen-free environment to promote the thermal decomposition reaction of organic materials. The pyrolysis reactor uses a rotating cylinder to complete the pyrolysis of materials during movement. Its advantage is that the material has strong adaptability and can handle raw materials of different shapes and properties.

When the organic material enters the pyrolysis furnace, the chemical bonds in the material gradually break under the high temperature of 300-800°C. Among them, water is evaporated first, and then volatile organic compounds (VOCs) begin to decompose to form small molecular synthetic gases, such as hydrogen, methane, carbon monoxide, etc. These synthetic gases can be used as fuel to provide part of the energy for the pyrolysis process.

As the temperature rises, the remaining solid matter further decomposes and condenses, and finally forms biochar. Throughout the process, it is crucial to strictly control the entry of oxygen. Oxygen will cause the organic material to undergo a combustion reaction, affecting the yield and quality of biochar.

Biomass Pyrolysis Plant Manufacturer

Mingjie Group is a professional Pyrolysis Plant Manufacturer in China. We have 20 years of rich experience and focuses on the research and development of pyrolysis technology and equipment. Their excellent performance ensures stable operation of the equipment. We provide one-stop service, including raw material analysis, equipment customization, installation, training and maintenance. Our biomass pyrolysis plant price is affordable and sold directly from the Mingjie factory.

As an efficient biomass energy resource conversion technology, biomass continuous pyrolysis technology is favored by various countries. Biomass pyrolysis equipment is developing towards high automation, strong pyrolysis continuity, and comprehensive and efficient combined recycling of biomass.

Biomass Pyrolysis Equipment for Sale

Biomass pyrolysis machine can convert a large amount of organic waste into biochar, effectively reducing the emission of organic waste. According to statistics, the amount of agricultural waste such as straw generated worldwide each year is huge. If it is not properly handled, it will not only cause waste of resources, but also produce greenhouse gases due to natural decomposition.

Through the pyrolysis treatment of biomass by biochar pyrolysis equipment, these wastes are converted into biochar. It not only reduces greenhouse gas emissions, but also biochar can be used for soil carbon sequestration, further helping carbon emission reduction.

Advanced biomass pyrolysis plant performs well in improving the efficiency and quality of Biochar production. The pyrolysis reactor adopts advanced heating technology and intelligent control system, which can accurately control the pyrolysis temperature and time. It enables biomass to complete the pyrolysis reaction in a shorter time, greatly improving production efficiency. Pyrolysis equipment can produce high-quality biochar by optimizing the internal structure and process parameters of the equipment.

In the long run, biomass pyrolysis equipment has the characteristics of reducing production costs and bringing economic benefits. Although the initial investment of equipment may be high, the production cost of unit biochar gradually decreases as the production scale expands.

As a soil conditioner, biochar can increase crop yields and reduce fertilizer use, thereby reducing agricultural production costs. As a fuel or fuel additive, it can partially replace traditional fossil fuels and save energy costs.