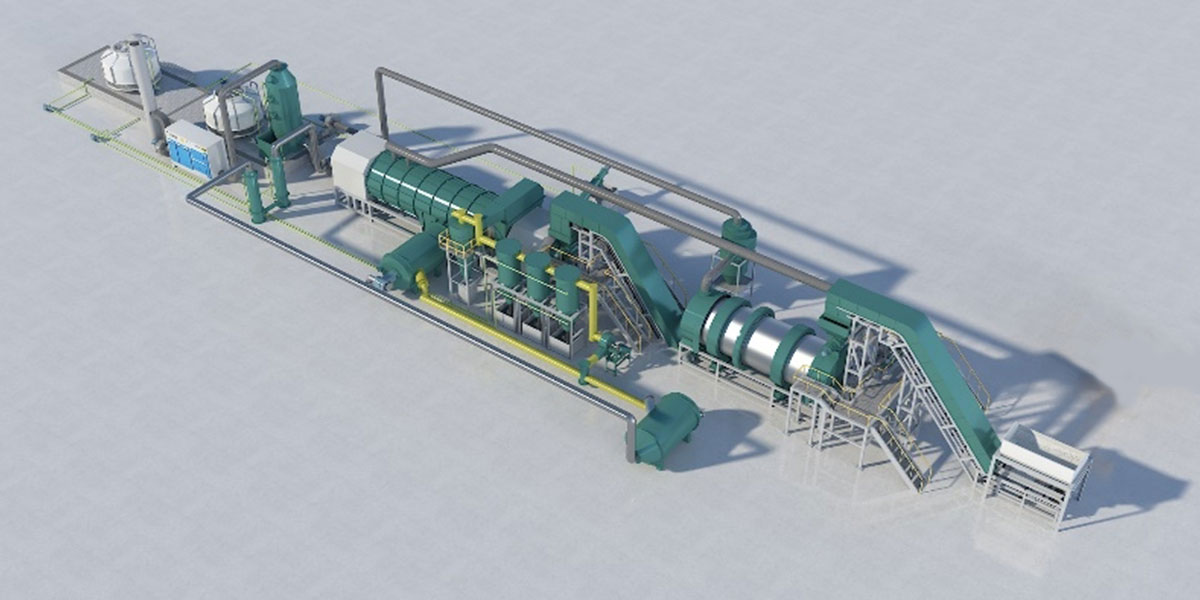

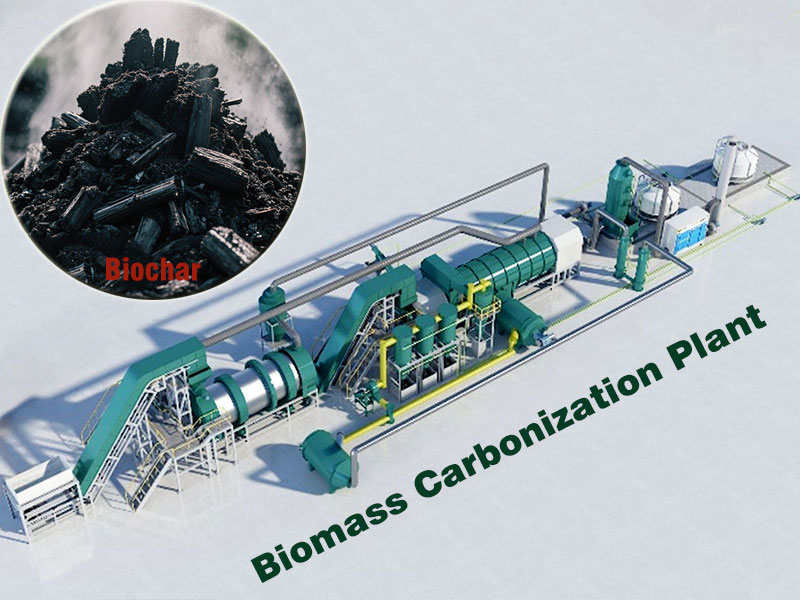

The application of pyrolysis technology makes the production process of biomass to biochar more efficient and environmentally friendly. Modern charcoal production machine mainly uses pyrolysis technology to make biochar. Biomass pyrolysis is carried out under anaerobic or oxygen-free conditions. By heating the reactor, the biomass inside undergoes thermochemical decomposition, thereby converting it into biochar, bio-oil and syngas.

Charcoal, this seemingly ordinary black solid, plays a pivotal role in human life and industrial development. In daily life, charcoal is a must-have for barbecue enthusiasts. In the cold winter, it becomes a good helper for heating. In the industrial field, charcoal is used as a reducing agent in the metallurgical industry. In chemical production, it also participates in many chemical reactions and is an indispensable raw material.

Charcoal production machine uses agricultural and forestry waste (sawdust, straw, rice husks) as the main raw materials. These waste biomass need to be screened and dried first to remove impurities and adjust the moisture content. So that the biomass raw materials can reach continuous pyrolysis and carbonization conditions.

Pyrolysis technology converts biomass waste into stable carbon – biochar, which can store carbon for a long time. This helps to mitigate carbon dioxide emissions, reduce greenhouse gas emissions and support the production of renewable energy.

Charcoal Production Machine Application

High efficiency charcoal production machine has broad application prospects in the fields of energy, agriculture, environmental protection, etc.

In the field of energy, biochar can be used as a solid fuel with high calorific value and low pollutant emissions. Synthesis gas can be used for power generation.

In the field of agriculture, biochar has rich pore structure and large specific surface area, which can be used as a soil conditioner to increase the soil’s water and fertilizer retention capacity, improve soil structure, and promote plant growth. At the same time, biochar can also adsorb heavy metals and organic pollutants in the soil, reducing their harm to the environment and human health.

In the field of environmental protection, the pyrolysis treatment of biomass waste not only realizes the resource utilization of waste, but also reduces the environmental pollution problems caused by traditional treatment methods, such as incineration.

Biomass Pyrolysis Projects

Here are some global biomass pyrolysis projects.

A US company uses wood chips as raw materials to produce biochar through biomass pyrolysis equipment. The charcoal is used for soil improvement products and water filtration. At the same time, the synthesis gas produced during the pyrolysis process is used as a new energy source.

A Finnish company uses biomass pyrolysis plant to convert short-cycle carbon stored in biomass into biochar. The excess energy from biomass pyrolysis is used for heating inside the factory.

An Ecuadorian company uses charcoal production machine to produce biochar from teak waste. It is mainly used for soil improvement in agriculture, aquaculture and bioremediation.

A Norwegian company uses pyrolysis machine to solve the problem of wastewater sludge treatment. Through drying and pyrolysis, wastewater sludge is converted into stable and odorless biochar.

How to Choose Charcoal Making Machine

In the process of biomass carbonization, the control of temperature and time is directly related to the quality of charcoal. Mingjie Charcoal Making Equipment adopts a fully continuous working mode. The temperature and time of biomass pyrolysis are controlled by an intelligent control system.

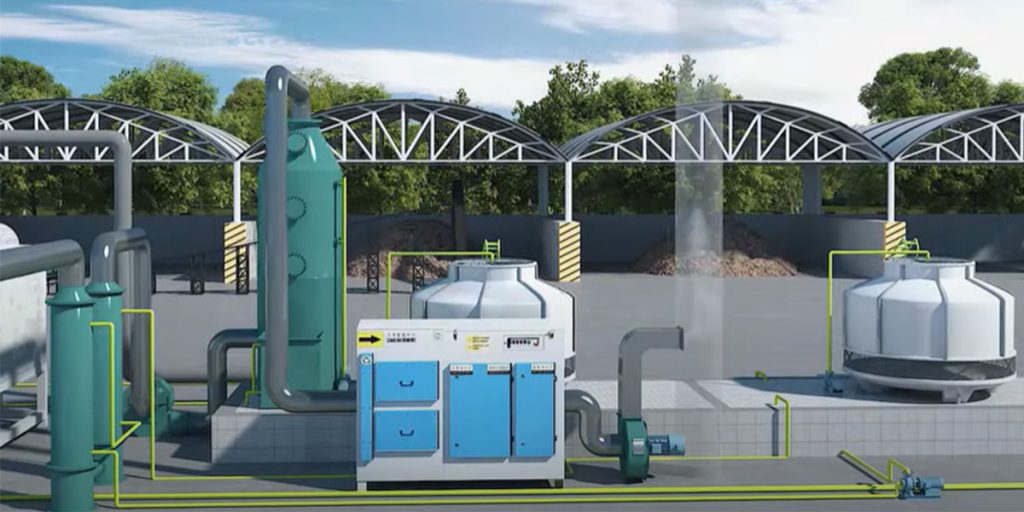

In addition, tail gas treatment is also an important link in the carbonization process that cannot be ignored. A large amount of tail gas will be generated during the carbonization process, including harmful substances, such as carbon monoxide, methane, and tar. If it is discharged directly, it will not only cause environmental pollution, but also pose a safety hazard. Therefore, it is important to choose a suitable charcoal making machine manufacturer.

Mingjie Group equips biomass charcoal making equipment with a special tail gas treatment device to purify the tail gas to meet environmental emission standards. At the same time, the combustible components in the tail gas can be recycled to improve energy utilization.

Biomass Pyrolysis Equipment Manufacturer

Henan Mingjie Environmental Protection Equipment Co., Ltd. is committed to global environmental protection and is one of the leading Biomass Pyrolysis Equipment Manufacturers in the world. We help utility and industrial customers improve performance while reducing environmental impact through pyrolysis technology.

We provide customers with one-stop services, including analysis of biomass pyrolysis solutions, charcoal making equipment manufacturing, installation, commissioning and training. It can provide strong guarantees for the sustainable and stable development of enterprises.

We can provide different pyrolysis solutions for different raw materials, such as sawdust, straw, fruit shells, etc. If the size of the raw material is too large, it needs to be crushed to less than 20mm. If the moisture content of the raw material is too high, it needs to be dried to less than 15%.

Installation and commissioning services of Biomass Charcoal Making Equipment are the prerequisite for the smooth commissioning of equipment. Mingjie’s professional installation team can carry out scientific and reasonable installation layout according to the characteristics of pyrolysis equipment and the actual situation of the production site. During the commissioning process, the various parameters of the equipment can be accurately adjusted to achieve the best operating state.