Many waste to energy (WTE) technologies are being used extensively around the world to produce energy on an industrial scale. Pyrolysis is considered a revolutionary alternative. It is a simple and clean waste treatment technology compared to other solid WTE technologies.

Municipal solid waste is disposed of in a variety of ways, such as landfill, composting, recycling, incineration, pyrolysis and gasification.

Pyrolysis technology can produce a variety of forms of chemicals and fuels. Pyrolysis solid waste to energy is usually the thermal degradation of waste in the absence of oxygen (or when oxygen supply is limited). It is an efficient and environmentally friendly technology that can use municipal solid waste as raw material to produce value-added products.

Among the products of municipal solid waste pyrolysis, fuel oil accounts for about 43%, carbon black accounts for about 27%, and syngas accounts for about 25%.

Solid Waste to Energy Technology

Solid Waste to Energy technologies can be divided into two categories. One is bioconversion technology, which can produce hydrogen, methane and other gaseous fuels. The other is thermal conversion technology, including incineration, gasification and pyrolysis.

Compared with other energy recovery technologies, pyrolysis technology has a wide range of applications, diverse raw material sources, fast processing speed, and low environmental pollution risk.

Pyrolysis is an irreversible process, and the raw materials for pyrolysis of solid waste are of various types. Under the influence of pyrolysis, the physical phase and chemical composition of the raw materials are constantly changing.

Types of Pyrolysis Technology

Slow Pyrolysis

Low temperature (usually 300-500°C), very slow heating rate (< 1°C/s or even as low as 0.1-1°C/min), long solid residence time (minutes to hours or even days).

The main goal of slow pyrolysis is to maximize the yield of biochar (35-50%), while producing some liquids and gases. Slow pyrolysis solid waste to energy is more focused on biochar production.

Medium Pyrolysis

Medium temperature (about 500-650°C), medium heating rate (1-10°C/s), medium residence time (several minutes).

Medium pyrolysis aims to balance the yields of three products: gas, liquid and solid. The yields of bio-oil and syngas are higher than slow pyrolysis, and the biochar yield is correspondingly lower.

Fast Pyrolysis

Moderately high temperatures (usually 450-600°C), very high heating rates (> 100-1000°C/s), very short vapor residence time (< 2 seconds), and rapid cooling of product vapors. Solid particle residence time is also very short (< 2 seconds).

The main goal of fast pyrolysis is to maximize the yield of liquid bio-oil (50-75%), while producing some gas and a small amount of carbon balck. Fast pyrolysis solid waste to energy is mainly used to produce liquid fuel oils.

Pyrolysis of Municipal Solid Waste

Pyrolysis can convert municipal solid waste to energy products, and its pyrolysis products usually have properties similar to fuel. The pyrolysis process of municipal solid waste to energy may have a negative impact on the environment, and advanced pyrolysis methods must be used to reduce and eliminate environmental pollution.

Municipal solid waste is usually not thoroughly sorted, and multiple components are mixed together. The choice of pyrolysis type depends mainly on the treatment target (pyrolysis products), raw material characteristics (components), technical maturity, economic feasibility, and environmental protection requirements.

Waste Biomass Pyrolysis

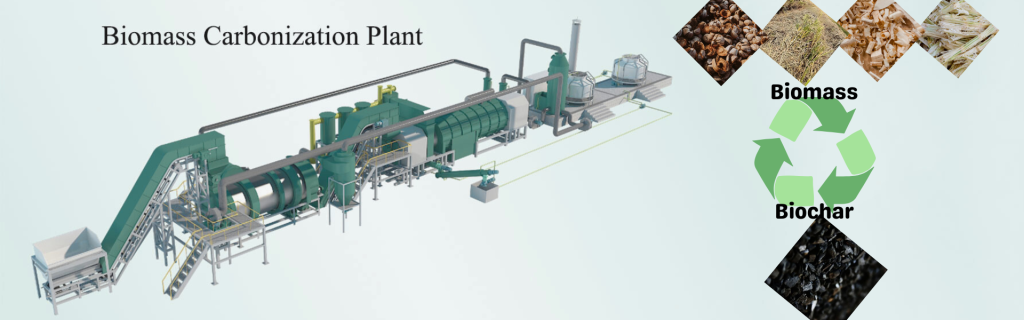

This type of biomass is rich in cellulose and hemicellulose, and low-temperature pyrolysis (350-500℃) is preferred. Biomass pyrolysis plant can convert biomass into biochar.

Plastic Rubber Pyrolysis

This type of material has a high calorific value (plastic calorific value is about 40MJ/kg) and is suitable for high-temperature pyrolysis (800-1000℃). In the pyrolysis reactor, plastic or rubber is converted into pyrolysis oil, carbon black and synthesis gas. It should be noted that chlorine-containing plastics (such as PVC) need to be pretreated separately, and the content of HCl in the pyrolysis gas is reduced by adding calcium carbonate dechlorination agent.

Mixed Waste Pyrolysis

When the composition is complex, the synergistic pyrolysis technology is used to improve the product quality by utilizing the complementarity of different materials. For example, when plastics and biomass are co-pyrolyzed, the oxygen element in the biomass can inhibit the coking of plastic pyrolysis, and the high hydrogen content of plastics can improve the calorific value of bio-oil. Batch pyrolysis plant has become the preferred equipment for large-scale processing due to its adaptability to mixed materials.

The main purpose of municipal solid waste pyrolysis is to recover energy, as the products produced by the pyrolysis process generally have properties similar to fuels. The pyrolysis process converts municipal solid waste to energy, and the energy products obtained through the pyrolysis process can be used to improve the operating efficiency of large-scale pyrolysis plants.

Summary

A large amount of organic waste (kitchen waste, straw, waste paper, plastic, rubber) in urban solid waste is the core object of pyrolysis treatment. It is rich in carbon and hydrogen elements and has extremely high resource potential. For the pyrolysis of such high-proportion organic waste, efficiency, product utilization and environmental protection must be taken into account.

The pyrolysis solid waste to energy relies on its high volatility and decomposability. In an oxygen-free environment, organic macromolecules (such as cellulose, lignin, and polymers) can be converted into small molecules (gas, liquid, and solid three-phase products) by breaking chemical bonds.

Compared with incineration, pyrolysis can reduce flue gas emissions by more than 90% and avoid the large-scale generation of highly toxic substances such as dioxins. At the same time, the pyrolysis products have a high energy density (such as the calorific value of bio-oil can reach 4000-5000kcal/kg), which can replace fossil energy and realize the solid waste to energy.