The pyrolysis treatment of municipal solid waste in pyrolysis equipment is a complex and orderly process. It converts waste into usable energy through a high-temperature oxygen-free or oxygen-deficient environment.

Municipal solid waste (MSW) contains a variety of different materials. A typical MSW mix consists mainly of food, wood waste, cardboard, glass and plastic waste. Due to the large uncertainty in the composition of MSW, it is difficult to predict the composition of its pyrolysis products. Therefore, MSW pyrolysis products are usually divided into carbon black, pyrolysis oil and syngas.

Pyrolysis Process of Municipal Solid Waste

Pretreatment Stage

Municipal solid waste has complex components, including kitchen waste, plastic, paper, fabric, glass, metal and other substances. Before entering the pyrolysis equipment, pretreatment is required to remove components that are not conducive to pyrolysis and improve pyrolysis efficiency.

The pretreatment steps usually include crushing and sorting. Crushing is to break large pieces of waste into smaller particles. Increasing its specific surface area is convenient for subsequent pyrolysis reactions.

Sorting is to separate glass, metal and other materials that are not pyrolyzable or have low pyrolysis value through manual or mechanical methods. At the same time, different types of solid waste are classified, so that pyrolysis parameters can be adjusted according to their characteristics.

Pyrolysis Treatment Stage

The MSW waste is sent to the pyrolysis treatment equipment and heated to a certain temperature under oxygen-free or oxygen-deficient conditions. The temperature is usually between 300-1000℃, and the specific temperature is determined according to the type of waste and the target product of pyrolysis treatment.

Under the action of high temperature, the organic components in the waste undergo a series of complex chemical changes, such as breaking chemical bonds, rearrangement, and decompose into three products: gaseous, liquid and solid.

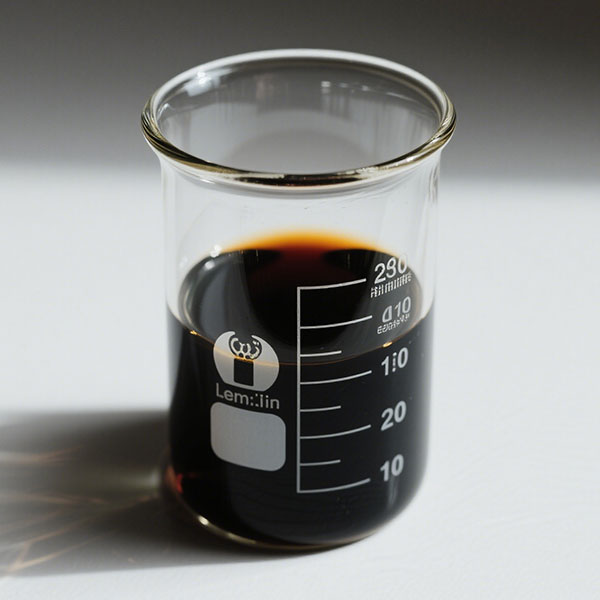

Gaseous products mainly include combustible gases, such as hydrogen, carbon monoxide, methane, and carbon dioxide. Liquid products are usually tar or pyrolysis oil, and solid products are biochar or carbon black.

The parameters (temperature, heating rate, residence time and reaction atmosphere) in the pyrolysis treatment process have an important influence on the distribution and properties of the products. It needs to be precisely controlled according to actual needs.

Product Separation and Purification Stage

The three-phase products of gas, liquid and solid produced by pyrolysis treatment are mixed together and need to be separated.

First, the solid coke or carbon black is separated by gravity sedimentation, cyclone separation and other methods.

Then, the gaseous and liquid mixture is cooled to condense the liquid product (tar or pyrolysis oil) and separate it from the gaseous product.

The separated gaseous and liquid products often contain some impurities, such as dust, sulfur compounds, nitrogen compounds, which need to be further purified. For example, the gaseous product can be improved by desulfurization, denitrification, dust removal and other processes to improve its purity. The syngas can be directly burned as fuel or used for power generation.

Liquid products can be removed from impurities by distillation, filtration and other methods. The distillation plant can improve its stability and combustion performance and can be used as fuel oil.

Finally, the various products obtained after separation and purification are stored and used according to their properties and uses. The small amount of residue produced during the pyrolysis process is safely disposed of to avoid pollution to the environment.

The entire pyrolysis treatment process achieves the reduction, harmlessness and resource utilization of MSW Waste through reasonable process design and parameter control.

MSW Waste Management Equipment

The management and disposal of Municipal Solid Waste (MSW) is a common concern in every country. Pyrolysis plant of MSW is considered an innovative alternative to treat MSW, from which different chemicals and fuels can be obtained.

The MSW pyrolysis plant can process many types of municipal solid waste, including domestic garbage, industrial waste, medical waste, etc. It has strong adaptability and flexibility.

Pyrolysis equipment operates in an oxygen-free or low-oxygen environment and produces almost no greenhouse gases such as methane and carbon dioxide. Compared with traditional landfill and incineration methods, it is more environmentally friendly.

In addition, the syngas produced by pyrolysis treatment of MSW Waste can be used as a clean energy source to further reduce carbon emissions. And there is less smoke emission and less impact on air quality.