Wood pyrolysis plant converts various types of waste wood into valuable biochar. Wood pyrolysis plant is also called biochar production equipment. It is a sustainable solution for reducing and recycling biomass waste.

Pyrolysis, torrefaction, thermal liquefaction, and gasification are well-known thermochemical technologies for converting biomass into high-value biofuels and chemicals. Pyrolysis is becoming the most important thermochemical process, particularly in organic waste treatment applications such as wood, garden waste, and food chain residues. Wood pyrolysis products primarily include biochar, syngas, and bio-oil.

Biochar is a solid, carbon-rich material. Syngas, a gaseous byproduct of the reaction, can be used as a heat source in the pyrolysis reactor. Bio-oil is a liquid byproduct of the process.

The composition and yield of the final wood pyrolysis product depend primarily on the process temperature: high temperatures (>700°C) produce syngas as the primary product, low temperatures (500-700°C) favor bio-oil, and temperatures <500°C yield biochar.

What is the Wood Pyrolysis?

Wood pyrolysis is a thermal degradation/decomposition process that occurs under oxygen-free conditions, producing bio-oil, biochar, and synthesis gas.

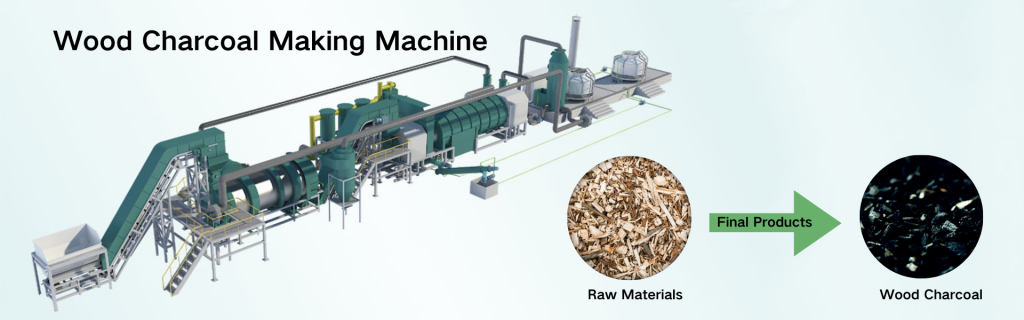

Raw Materials: Wood

Wood pyrolysis typically uses various forms of clean wood residues and waste from forestry and wood processing, including wood chips, sawdust, and branches. The core components are cellulose, hemicellulose, and lignin, which form the basis for biochar production through pyrolysis.

Pyrolysis Process

Wood pyrolysis requires two essential core conditions: high temperature and the absence of oxygen.

High temperature promotes the release of volatile organic compounds (VOCs) in biomass, such as water and alcohols, which primarily contain hydrogen and oxygen. Anaerobic or low oxygen conditions prevent the carbon from burning into carbon dioxide (CO₂). Furthermore, they keep most of the carbon in a solid state, ultimately forming biochar.

End Product: Biochar

Biochar is the stable, carbon-rich solid residue left after the pyrolysis of wood. Biochar offers numerous environmental and agricultural benefits, thanks to its unique porous structure and high stability.

This porous structure gives biochar a high surface area and strong adsorption capacity, allowing it to store water and nutrients. Biochar’s aromatic carbon structure also imparts strong chemical stability, enabling it to remain in the soil for centuries.

Biomass Carbonization Plant Manufacturer

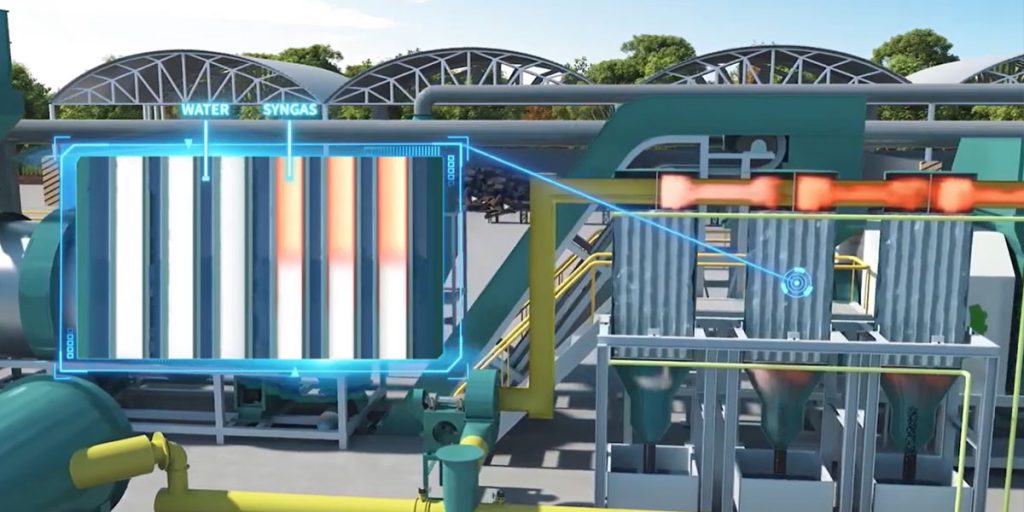

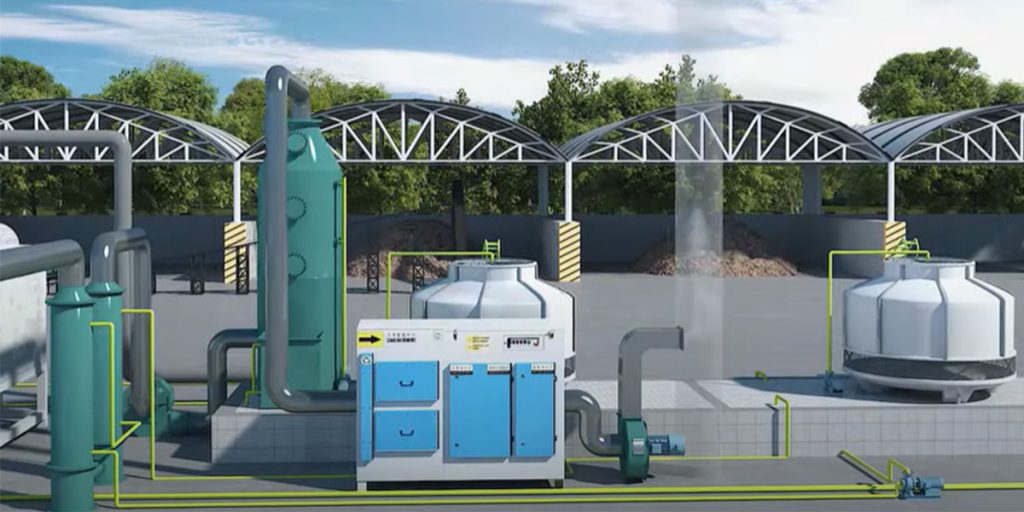

Mingjie biomass carbonization plant achieves continuous pyrolysis of biomass feedstock through automated feeding and discharging. It is a leading choice for industrial biochar production. This biomass carbonization plant primarily includes a feeding system, pyrolysis reaction system, slag discharge system, cooling system, and purification system.

In terms of energy recycling, biomass carbonization plant uses waste heat recovery devices to convert the combustible gas into a heat source for pyrolysis reactor, increasing energy self-sufficiency to over 70%.

In terms of pollutant control, biomass carbonization plant installs flue gas purification system to keep flue gas concentrations below emission standards.

The core advantages of continuous pyrolysis equipment lie in its high degree of automation, low energy consumption, and consistent product quality. However, the initial investment is relatively high, and it requires complementary feedstock pretreatment (crushing and drying), making it more suitable for large-scale biomass recycling enterprises.

Wood Biochar Production Equipment Market

The application of biochar production equipment has expanded beyond traditional agriculture to encompass a wide range of sectors, including environmental protection and energy.

In soil remediation, small mobile biomass pyrolysis equipment can process biomass waste from contaminated soil on-site. The biochar produced is directly used to improve the soil, eliminating material transportation costs.

In solid waste management, large-scale continuous biochar production equipment is integrated with waste incineration plants. Co-pyrolysis of fly ash and biomass achieves the dual goals of heavy metal stabilization and carbon sequestration.

As the core equipment for biomass resource utilization, biochar production equipment will directly drive the large-scale development of the biochar industry. From small-scale biomass pyrolysis equipment in farmlands to large-scale biochar production lines in industrial parks, these wood pyrolysis equipment are transforming dispersed biomass resources into green, low-carbon “black gold,” providing solid support for achieving global carbon neutrality goals.