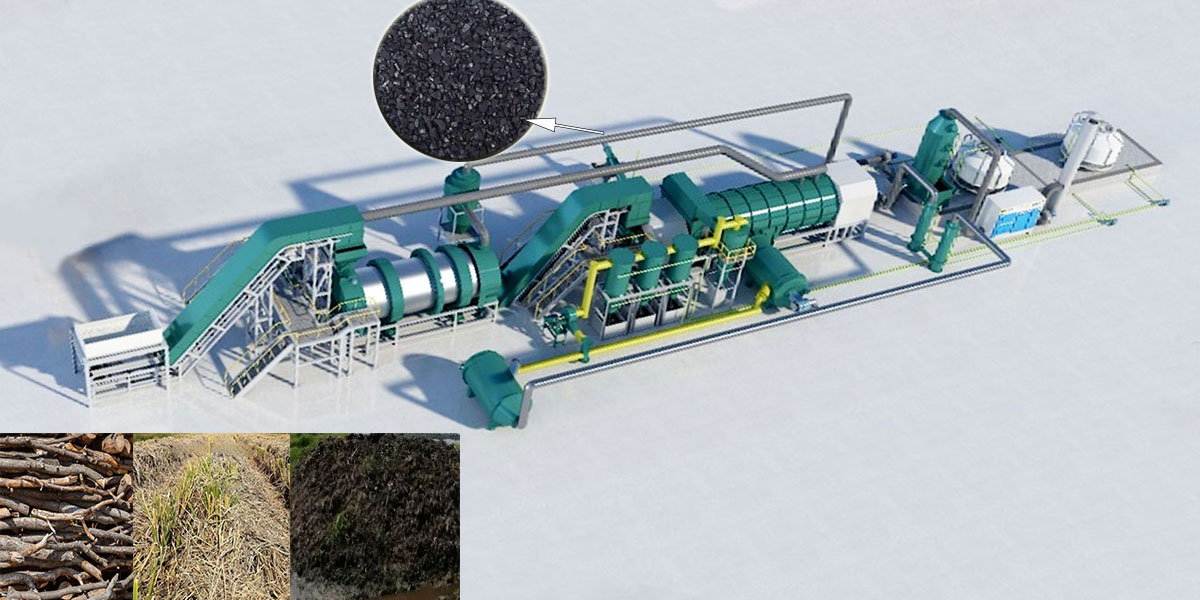

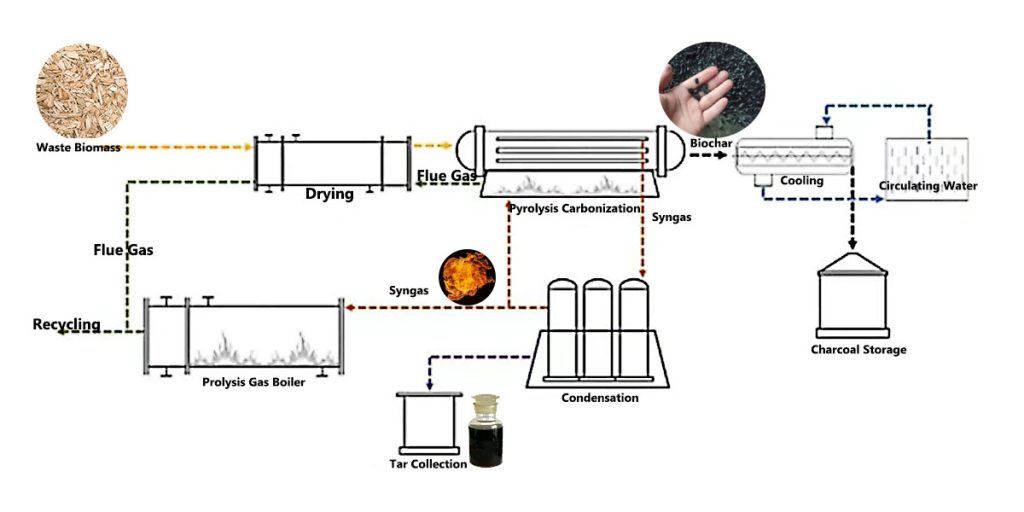

Mingjie biochar making equipment is a sustainable waste biomass solution. It uses biomass pyrolysis technology to convert biomass into a solid carbonaceous material – biochar under oxygen-free and high-temperature conditions. The biochar making machine can process a variety of biomass raw materials, including agricultural waste, forestry residues, and organic waste (rice husks, wood chips, straw, or livestock and poultry manure).

Biochar making equipment converts this biomass into biochar, which possesses high carbon content and a porous structure. The chemical stability of biochar allows it to persist in soil for long periods of time, and it can also serve as a physical adsorption material. Due to its unique pore structure and chemical properties, bio charcoal has broad potential applications in agriculture, environmental remediation, and carbon sequestration.

The biomass pyrolysis to biochar production process offers environmental benefits. Volatile gases released during pyrolysis can be captured and converted into energy, thereby reducing greenhouse gas emissions.

According to the International Biochar Initiative, each ton of biochar produced sequesters approximately 2.5-3 tons of carbon dioxide equivalent, equivalent to the carbon emissions from traditional incineration or composting.

This characteristic makes biochar a crucial player in addressing climate change. Biochar making equipment applications are expanding.

Biochar Making Equipment in Environmental Protection Application

In terms of environmental applications, biochar production equipment offers a new solution for waste management. It can process agricultural and forestry waste, sewage sludge, animal manure, and other organic waste.

In recent years, biochar produced by biochar making equipment has emerged as a highly effective carbon reduction tool. Its stable, solid carbon structure enables long-term storage of biomass carbon. Furthermore, its porous nature inhibits the production of potent greenhouse gases in anaerobic environments.

As a low-carbon alternative, biochar can reduce the reliance of high-carbon-emitting industries on industrial raw materials and agricultural inputs. Through a synergistic mechanism of “carbon sequestration, emission reduction, and substitution,” it achieves a full-cycle carbon footprint reduction effect.

Agricultural Applications

Carbon Sequestration: Biochar produced by biomass carbonization plant has a highly porous structure. It absorbs soil organic matter and slows microbial decomposition, thereby extending carbon retention to hundreds of years.

Soil Improvement: Biochar promotes soil aggregation, enhancing water and fertilizer retention. It indirectly supports plant photosynthesis and root carbon input.

Combustion Alternative: Mingjie biochar making equipment converts agricultural waste into biochar through pyrolysis technology. This prevents direct CO2 emissions from combustion and indirect emissions from accelerated decomposition of soil organic matter.

Compost Optimization: Biochar improves compost aeration and inhibits CH₄ formation under anaerobic conditions. It also absorbs nitrogen, reducing N₂O emissions.

Nitrogen Adsorption: Biochar absorbs NH₄⁺ and regulates soil pH, inhibiting nitrification and denitrification, thereby reducing N₂O emissions by 20%-30%.

Fertilizer Addition: Biochar-based compound fertilizers can reduce chemical fertilizer use by 25%-30%. This indirectly reduces the high energy consumption and emissions associated with fertilizer production.

Forestry Applications

Reduced Incineration and Landfilling: Biomass pyrolysis plant can pyrolyze branches, bark, and other waste into biochar. This prevents the carbon dioxide produced by open-air burning and the methane produced by landfilling.

Reduced Transportation Energy: Mobile biomass pyrolysis machine can be moved near forests, reducing the energy consumption of long-distance transportation of wood/wood chips.

Improved Soil Conditions: Biochar can increase soil fertility and water retention in reforested areas. This accelerates tree growth and increases carbon sequestration per unit area.

Ecosystem Restoration: Biochar accelerates vegetation recovery in degraded or post-disaster areas, compensating for carbon losses caused by over-logging or forest fires.

Fuel load reduction: Biochar making equipment can produce biochar by processing deadwood and waste. This can reduce the likelihood of wildfires and the long-term carbon loss after disasters.

Fire retardant and protective: Biochar applied to soil can inhibit the spread of fire. After a fire, applying biochar helps reduce soil erosion and preserve carbon stocks in unburned vegetation.

Livestock Applications

Inhibiting Methane Production: Biochar can be added to animal feed to absorb substrates for methane-producing archaea in the rumen, thereby reducing CH₄ emissions. Biochar alters rumen fermentation patterns, lowering the acetic acid/propionic acid ratio and thus reducing methane-producing pathways.

Optimizing Manure Management: Biochar produced by Biochar Making Equipment inhibits the activity of anaerobic microorganisms. As a bedding material or additive, it can reduce methane emissions from liquid manure and nitrous oxide emissions from solid compost. Biochar absorbs ammonia (NH₃) and phosphorus from manure, converting them into slow-release organic fertilizer, indirectly reducing carbon emissions from fertilizer production.

Improving Feed Efficiency: Biochar improves feed absorption efficiency. This reduces feed requirements and direct feed-related emissions. It also indirectly reduces emissions during the growth of feed. Higher feed conversion rates promote faster growth and shorten the production cycle, thereby reducing cumulative emissions per unit weight.

Industrial Applications

Cement Additive: Biochar can replace part of the cement used in production, directly reducing the need for limestone calcination, which accounts for 60% of cement emissions. Biochar improves concrete workability and reduces the water-cement ratio. It reduces the amount of cement required to achieve the same strength, thereby reducing CO2 emissions.

Replacing Traditional Fuels: Biochar Making Equipment adopts pyrolysis technology to produce biochar and syngas, which can replace coal in cement kiln heating, reducing fossil fuel consumption. Biochar raw materials have significantly lower sulfur and nitrogen contents than fossil fuels. As a fuel, it not only reduces CO2, but also reduces emissions of pollutants such as sulfur dioxide and nitric oxide.

As a Reducing Agent: Biochar can replace 5%-10% of coke in the carbon reduction reaction (C + Fe₂O₃ → Fe + CO₂), reducing fossil carbon consumption. Biochar’s porous structure increases the reaction surface area, improving reduction efficiency. It also avoids the high-temperature coking emissions generated during coke production.