Biomass carbonization technology, as a core technology for converting biomass into high-value-added carbon materials, is gaining increasing attention and application worldwide. Against the backdrop of global climate change and energy transition, biomass carbonization projects are being implemented and applied in various countries. It not only provides a sustainable way to utilize biomass resources, but also offers innovative solutions for carbon sequestration, soil improvement, and clean energy production.

Definition of Biomass Carbonization Technology

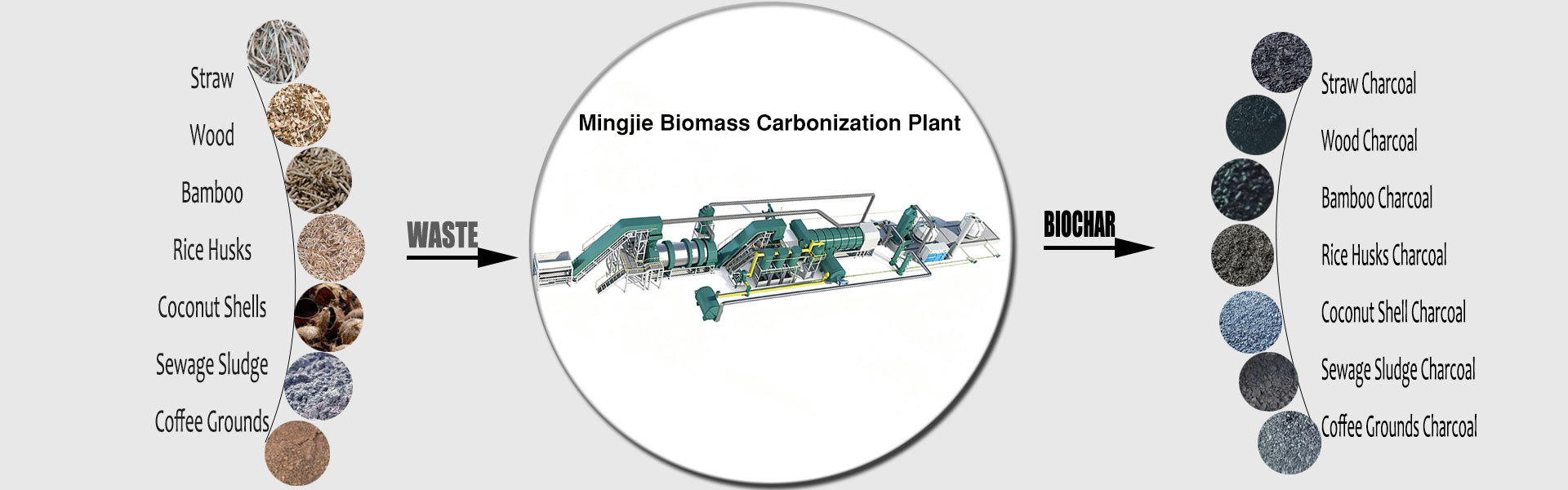

Biomass carbonization refers to the process of converting biomass materials into products such as biochar, syngas, and tar through thermochemical conversion in an oxygen-deficient or low-oxygen environment. By controlling parameters (temperature, heating rate, and residence time), this technology can achieve efficient biomass conversion and maximize resource utilization.

Core Values of Biomass Carbonization Projects

Carbon Sequestration Potential: Biochar, the primary product of carbonization, has a highly stable carbon structure. It can sequester carbon in the soil for long periods of time, reducing carbon emissions.

Soil Improvement: Biochar has a porous structure and high surface area. It improves soil structure, enhances soil water and fertilizer retention, and promotes plant growth.

Energy Production Path: The syngas and bio-oil produced during the biomass carbonization process can be used as clean energy, realizing the utilization of biomass for energy.

Waste Resource Utilization: Biomass such as agricultural waste and forestry residues can be converted into high-value-added products. The biomass carbonization project reduces waste disposal pressures and promotes the development of a circular economy.

Global Biomass Carbonization Market Development Overview

According to the latest market research data, the global biomass carbonization project market is experiencing rapid growth. The global biochar market reached US$2.196 billion in 2023 and is projected to grow at a compound annual growth rate of 9.27% from 2023 to 2028. This market is expected to achieve a compound annual growth rate of 9.27%.

Regionally, North America (the United States and Canada) leads in the research and development of biomass carbonization technology. Their biomass carbonization projects are widely used in agricultural waste treatment, soil improvement, and energy generation. Europe, on the other hand, demonstrates strong policy support and industrial application. For example, Finland has built Europe’s largest biochar production plant, producing 60,000 tons of biochar products annually.

Global biomass carbonization project investors primarily include venture capital firms, industrial capital, government funding, and international climate funds. Investment hotspots are primarily focused on biochar carbon sequestration, biomass energy utilization, biomass pyrolysis equipment manufacturing, and biochar high-value applications.

The biomass carbonization industry chain mainly includes raw material supply, pretreatment, carbonization conversion, product processing and product application.

Application Areas of Biomass Carbonization Projects

Biochar, as a soil conditioner, has broad application prospects in agriculture. It can improve soil structure, retain nutrients, regulate soil pH, and boost crop yields. Studies have shown that adding 5% biochar to farmland increases crop yields by an average of 12%-20% and improves nitrogen fertilizer utilization by 30%.

Combining biomass carbonization with power generation is an important approach to biomass energy utilization. For example, one company uses agricultural and forestry waste straw as its primary fuel, converting the biomass into combustible gas and then burning it with coal. This ultimately achieves synergistic power generation from biomass and coal-fired units.

Biochar has extensive applications in pollutant adsorption and environmental remediation. Modified biochar can adsorb up to 119 mg/g of lead and cadmium, 1.8 times that of activated carbon. Biomass carbonization technology also provides an effective approach for waste reduction and resource utilization.

Biomass carbonization products have broad application prospects in industrial fuel and energy substitution, functional materials and composite materials. For example, one company uses pyrolysis technology to convert biomass waste into high-performance biochar for industrial applications such as steel manufacturing, concrete reinforcement, and advanced filtration.