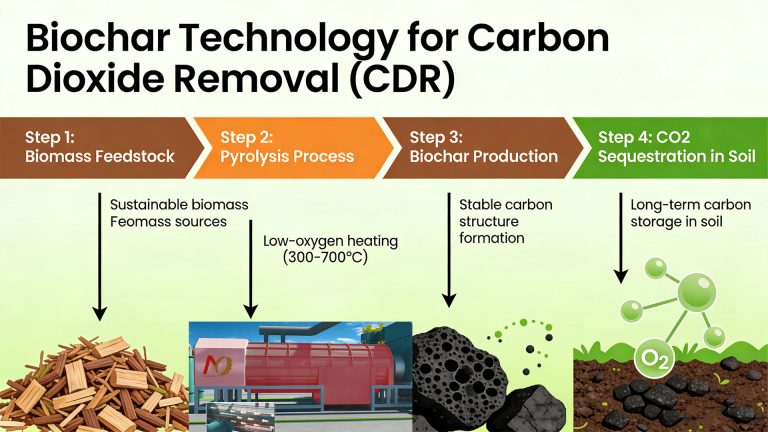

Biochar making plant is specifically designed to convert biomass into biochar. Its core function is to achieve this transformation through the thermochemical conversion process of pyrolysis and carbonization.

Biomass, the raw material for biochar production, comes from a wide range of sources. It includes agricultural waste (straw, rice husks, corn cobs), forestry residues (wood chips, branches), livestock and poultry manure, and even some industrial organic waste.

Biochar has high carbon content, rich nutrients, strong stability, and a well-developed pore structure. Known as “black gold,” it promotes soil health, remediates ecological pollution, and reduces greenhouse gas emissions.

Key Components of Modern Biochar Making Plant

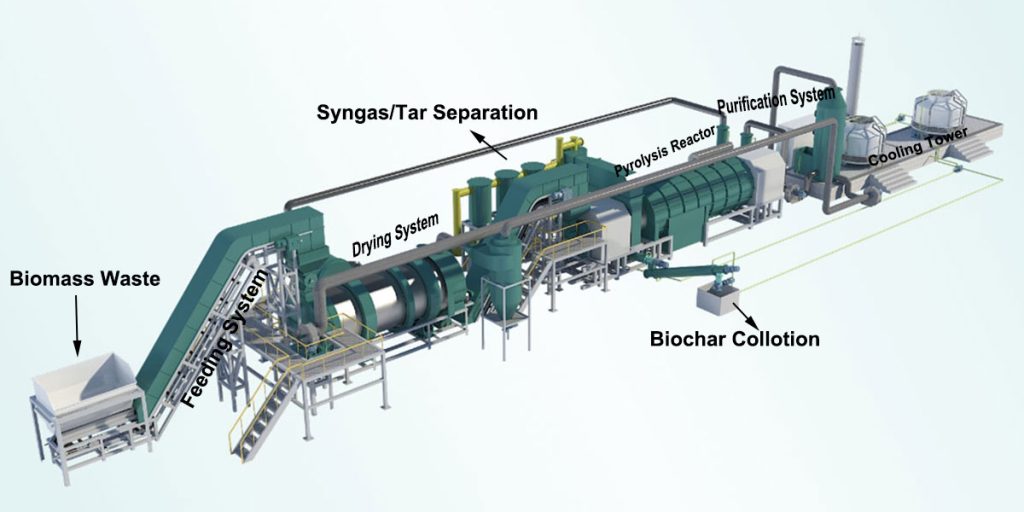

A mature biochar making plant is much more than just a reactor, it typically includes the following key modules.

Pretreatment System: This includes crushers, pulverizers, and dryers. It primarily processes the raw materials to the appropriate size and moisture content to ensure carbonization efficiency and product quality.

Feed System: This utilizes devices such as screw conveyors and sealing valves. It ensures continuous, stable, and sealed feedstock flow into the reactor, preventing oxygen from entering.

Pyrolysis Reactor: The heart of the biochar making plant, where the biomass pyrolysis reaction occurs. Its design directly determines the yield and quality of the charcoal produced.

Combustible Gas Recovery and Purification System: The syngas generated during the pyrolysis process is cooled and purified before being fed to the burner to provide heat for the system. This syngas enables the biochar production plant to be energy self-sufficient.

Charcoal Discharge and Cooling System: This system rapidly and oxygen-free discharges and cools the high-temperature biochar. This prevents combustion and oxidation in the air, ensuring high biochar yield and quality.

Exhaust Gas Treatment System: Purifies final exhaust gases to ensure compliance with environmental standards.

Intelligent Control System: Utilizing PLC control, it precisely controls and monitors key parameters such as temperature, pressure, and feed rate, ensuring a stable and safe production process.

Current Status of Biochar Plants

In recent years, biochar making plants have shown a booming development momentum and are expanding globally. According to relevant statistics, the number of biochar plants worldwide has grown at an annual rate of approximately 15% over the past decade. And their distribution has gradually expanded from a few developed countries to all corners of the globe.

In North America, Canada’s Carbonity biochar making plant has become a rising star in the industry. A joint venture between Airex Energy, Groupe Rémabec, and SUEZ, it is located in Port-Cartier, Quebec. It has an annual production capacity of 10,000 tons of biochar and is expected to triple by 2026. By then, it will be the largest plant of its kind in North America and a major player in the global biochar plant market.

In Europe, several countries are actively promoting the development of the biochar industry. A French biochar plant focuses on the application of biochar in soil improvement and horticulture. It has collaborated with local agricultural enterprises and research institutions to carry out multiple demonstration projects, achieving significant economic and environmental benefits.

Biochar plants are also developing rapidly in Asia. As a major agricultural country with abundant biomass resources, China’s biochar industry has enormous development potential. In recent years, the number of biochar plants in China has continued to increase, and their technological level has gradually improved.

Mingjie Group specializes in the research and development of biomass pyrolysis technology and the manufacture of biochar making machine. Our biomass carbonization plants have been used in biochar production projects in numerous countries, including South Africa, Tanzania, Japan, and Vietnam.

Mingjie biochar making plant operates in a fully continuous process, with simultaneous carbonization and feeding. The pyrolysis temperature of the reactor is adjusted during operation to ensure stable biochar quality. The syngas generated during the biochar production process is also purified and recovered.