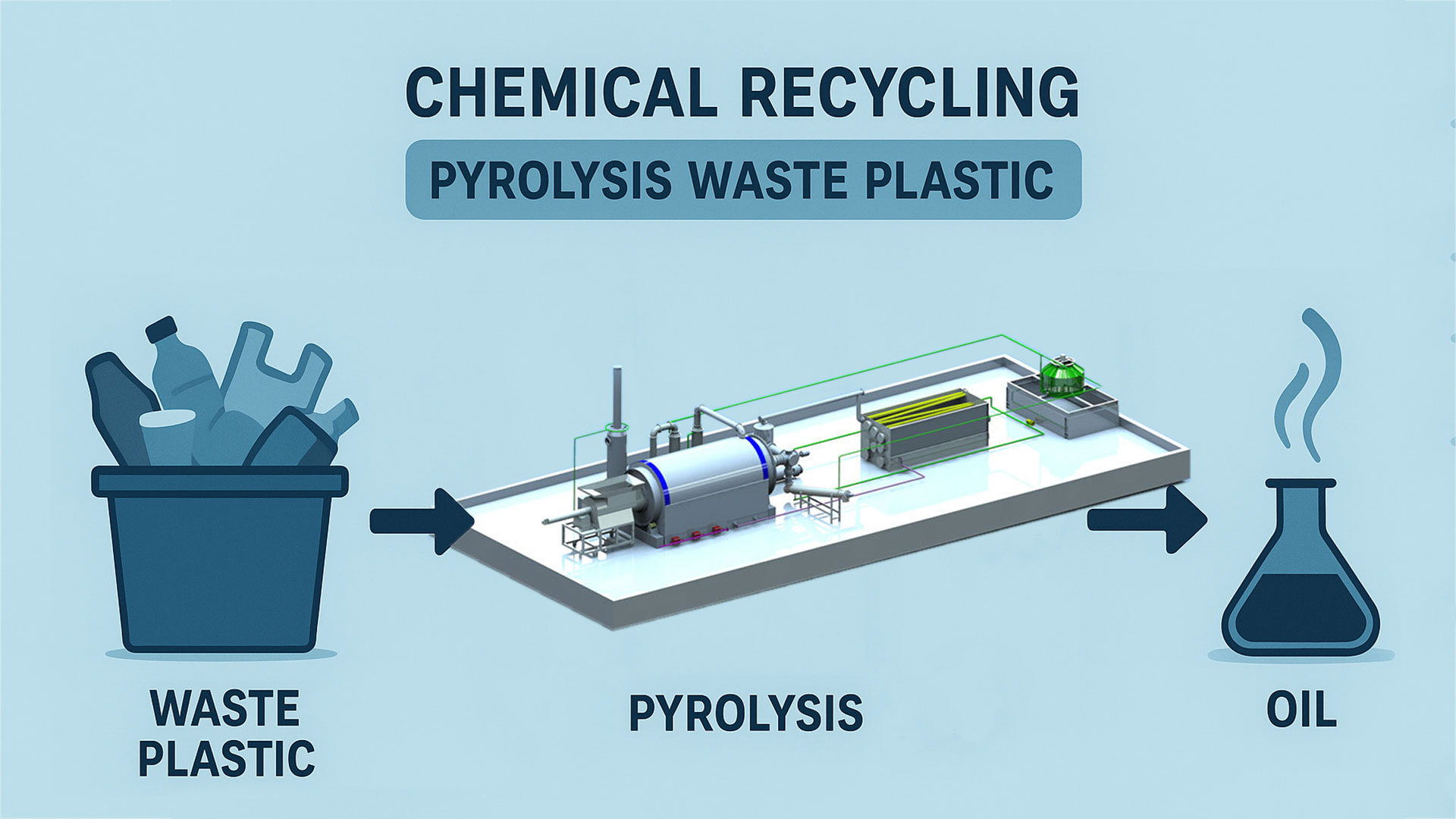

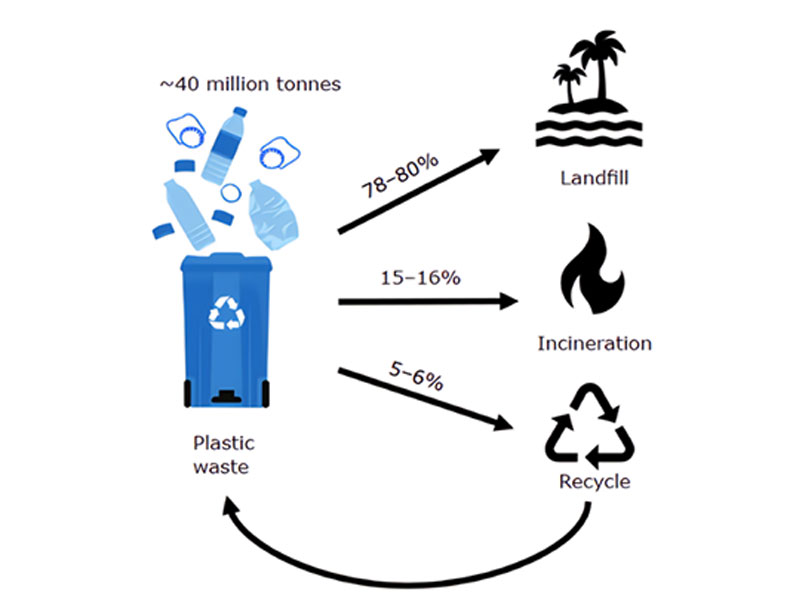

Pyrolysis is the core technology of chemical recycling, which can convert waste plastics into fuel oil and achieve recycling. Compared to traditional landfill and incineration, chemical recycling pyrolysis is the most efficient and environmentally friendly method for solving waste plastic pollution problems. Pyrolysis Plant achieves zero toxic gas leakage and no pollution during waste plastic treatment, resulting in higher economic benefits.

Comparison of Different Waste Plastic Treatment Methods

| Mechanical Recycling | Incineration | Gasification | Chemical Recycling Pyrolysis |

| The technology is mature. It cannot handle mixed/multi-layered/contaminated plastics. | High-temperature combustion combined with waste heat power generation requires significant investment in pollution control. It emits 1 t of Co2 per t of plastic and generates dioxins from the chlorine source. | Partial oxidation at 800-1200℃ yields syngas, but the tar and fly ash are difficult to treat. The equipment is large and requires high investment. | Oxygen-free pyrolysis at 350-900 ℃, with adjustable product distribution. Highly adaptable to mixed plastics, producing oil, gas, and carbon phases. |

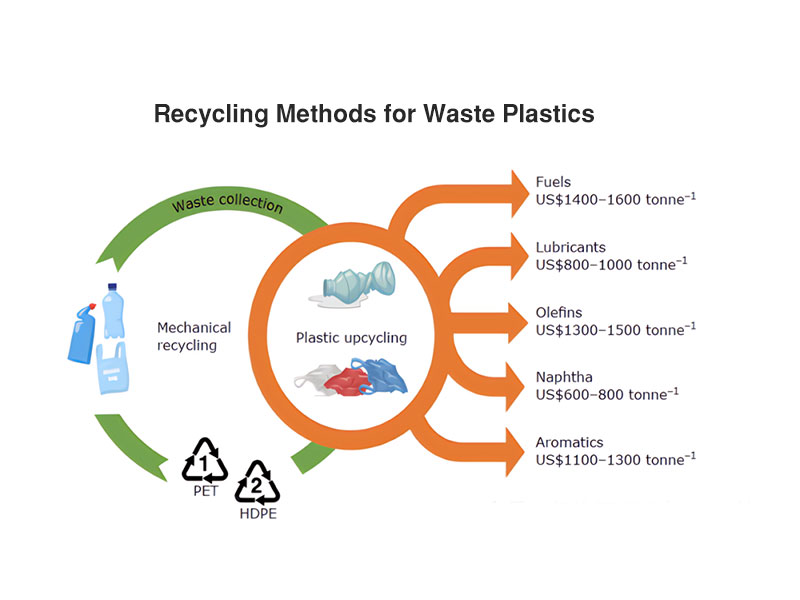

Chemical recycling pyrolysis plastic is an effective resource utilization pathway. It can transform waste plastics into high-value-added chemicals, such as fuels and basic chemical raw materials.

Chemical recycling pyrolysis involves heating plastics at high temperatures to break down the chemical bonds in the polymer, thus decomposing the plastic molecules. Plastic pyrolysis products include combustible gases, fuels, and carbon black. Plastic pyrolysis is highly flexible and can handle highly polluting and highly heterogeneous plastics.

Plastic Recycling in Europe

European recyclers are facing soaring energy costs, skyrocketing import costs of waste plastics, and fierce competition from cheap imported materials.

Data shows that from the beginning of 2025 to July, Europe’s lost plastic recycling capacity was already close to the level of the entire year of 2024. By August, the capacity loss was three times that of the same period in 2023.

In October of this year, Wipa GmbH, a well-known German manufacturer of specialized machinery founded in 1982, filed for bankruptcy. Due to a sharp decline in orders and persistent liquidity problems, it became the first casualty of this crisis.

The Mol Group has closed its Remat machinery recycling business, and is collaborating with Lummus Technology to build a 40,000-ton-per-year plastic pyrolysis plant in Tisza, Hungary. Chemical recycling pyrolysis can handle mixed and contaminated plastic waste that is difficult to process using mechanical recycling methods. It complements mechanical recycling methods.

Compared to 2022, total EU plastic production fell by 8.3% to 54 million tons. Mechanically recycled post-consumer plastic production fell by 7.8% to 7.1 million tons. Meanwhile, EU exports of plastic waste to non-OECD countries surged by 36% in 2024.

The European Plastics Recycling Association (PRE) estimates that Europe needs 16 million tons of recycling capacity by 2025 to reach the PPWR target. However, this is clearly insufficient at present. The growth rate of recycling capacity has already slowed to 6% in 2023, far below the 17% in 2021.

Chemical Recycling Pyrolysis Solution for Circular Economy

Chemical recycling pyrolysis offers Europe a crucial technological pathway to address plastic pollution and reduce its reliance on fossil fuels.

Pyrolysis technology is considered a key component in promoting a circular economy for plastics in Europe. It primarily processes mixed, contaminated, or mechanically difficult-to-recycle plastic waste. Pyrolysis machine converts this waste into pyrolysis oil through high-temperature cracking, allowing it to re-enter the production chain of new plastics.

As a professional pyrolysis equipment manufacturer, Mingjie Group has provided perfect solutions for numerous plastic pyrolysis projects. Our pyrolysis plants are used in plastic recycling projects in the Philippines, Thailand, Malaysia, Romania, Czech Republic, and other countries.

We offer a variety of pyrolysis equipment models, including the MJ-2 small skid-mounted pyrolysis machine, the MJ-6 MJ-10 MJ-12 MJ-15 batch pyrolysis unit, the MJL-15 semi-continuous pyrolysis equipment, and the MLL-20T MLL-20P MLL-30T fully continuous pyrolysis system.