Globally, approximately 9 million tons of coffee powder are consumed annually, generating about 18 million tons of wet coffee grounds. Most of these coffee grounds are treated as waste, disposed of through landfills or incineration. Pyrolysis carbonization technology offers a completely new approach to coffee grounds waste disposal, transforming them into biochar. Pyrolysis equipment can realize the resource utilization, carbon reduction, and value creation of coffee grounds.

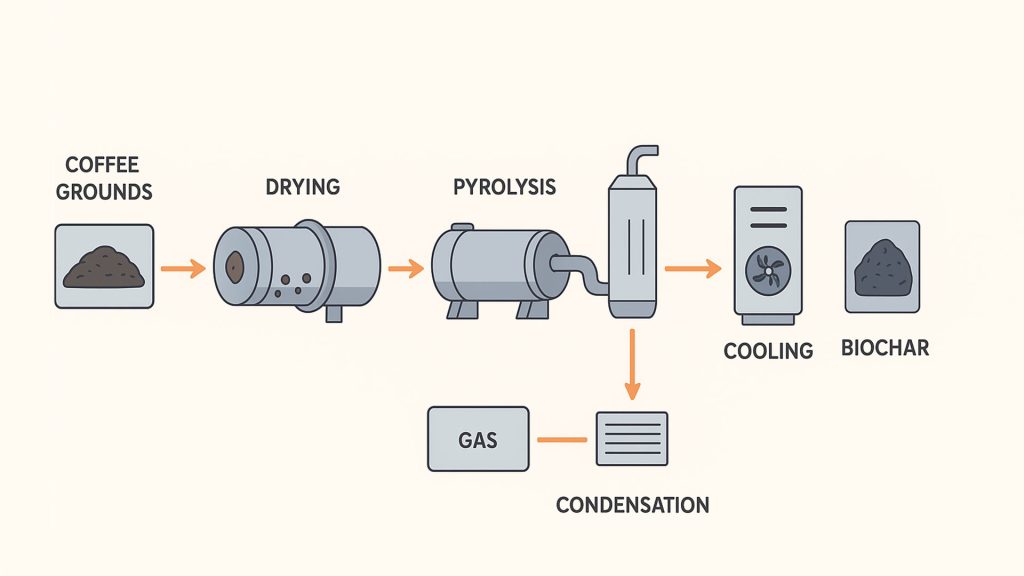

When coffee grounds are placed in pyrolysis machine, within a temperature range of 300-800℃, the large organic molecules in the coffee grounds gradually undergo bond-breaking reactions. Components such as cellulose, hemicellulose, and lignin decompose, transforming into small-molecule gases, liquid tar, and solid biochar.

This pyrolysis coffee grounds waste disposal process is fundamentally different from traditional incineration. Incineration is a violent oxidation reaction carried out under fully oxygenated conditions, producing large amounts of pollutants, such as carbon dioxide and nitrogen oxides.

Pyrolysis carbonization, on the other hand, takes place in a low-oxygen or anaerobic environment, effectively avoiding the formation of harmful substances. Carbon emissions can be reduced by 30%-50% compared to incineration, significantly reducing negative environmental impacts. Biomass carbonization machine can also convert coffee grounds into biochar and syngas, realizing the transformation from waste to resource.

Raw Materials for Biochar Production

Coffee grounds are an ideal raw material for biochar production due to their unique composition. Rich in carbon, coffee grounds provide an ample carbon source for biochar formation, with a carbon content ranging from 40% to 60%. They also contain abundant organic matter such as cellulose, hemicellulose, and lignin, as well as minerals like nitrogen, phosphorus, and potassium. These components interact during pyrolysis and carbonization, endowing biochar with unique physical and chemical properties.

A Dutch company processes hundreds of thousands of tons of coffee grounds annually. It converts coffee grounds into biochar for agricultural soil improvement and air purification. Its coffee grounds biochar products are sold in many European countries, generating annual revenue exceeding ten million euros.

Mingjie biomass carbonization equipment utilizes continuous pyrolysis technology to heat and decompose organic matter in coffee grounds under anaerobic conditions, producing biochar, bio-oil, and syngas. It achieves significant volume reduction (over 80%). The resulting biochar can be used for soil amendment or as fuel, and is eligible for carbon trading (Biochar Carbon Credit).

Coffee grounds biochar plays a positive role in soil improvement and carbon sequestration. After being applied to the soil, biochar increases its carbon content and enhances its carbon sequestration capacity.

Soil microorganisms can slowly decompose the carbon in the biochar, converting it into stable soil organic matter. This process can continue for decades or even centuries, thus achieving long-term carbon fixation. Simultaneously, biochar can improve soil structure, increase soil fertility, promote plant growth, and reduce the amount of chemical fertilizers used.

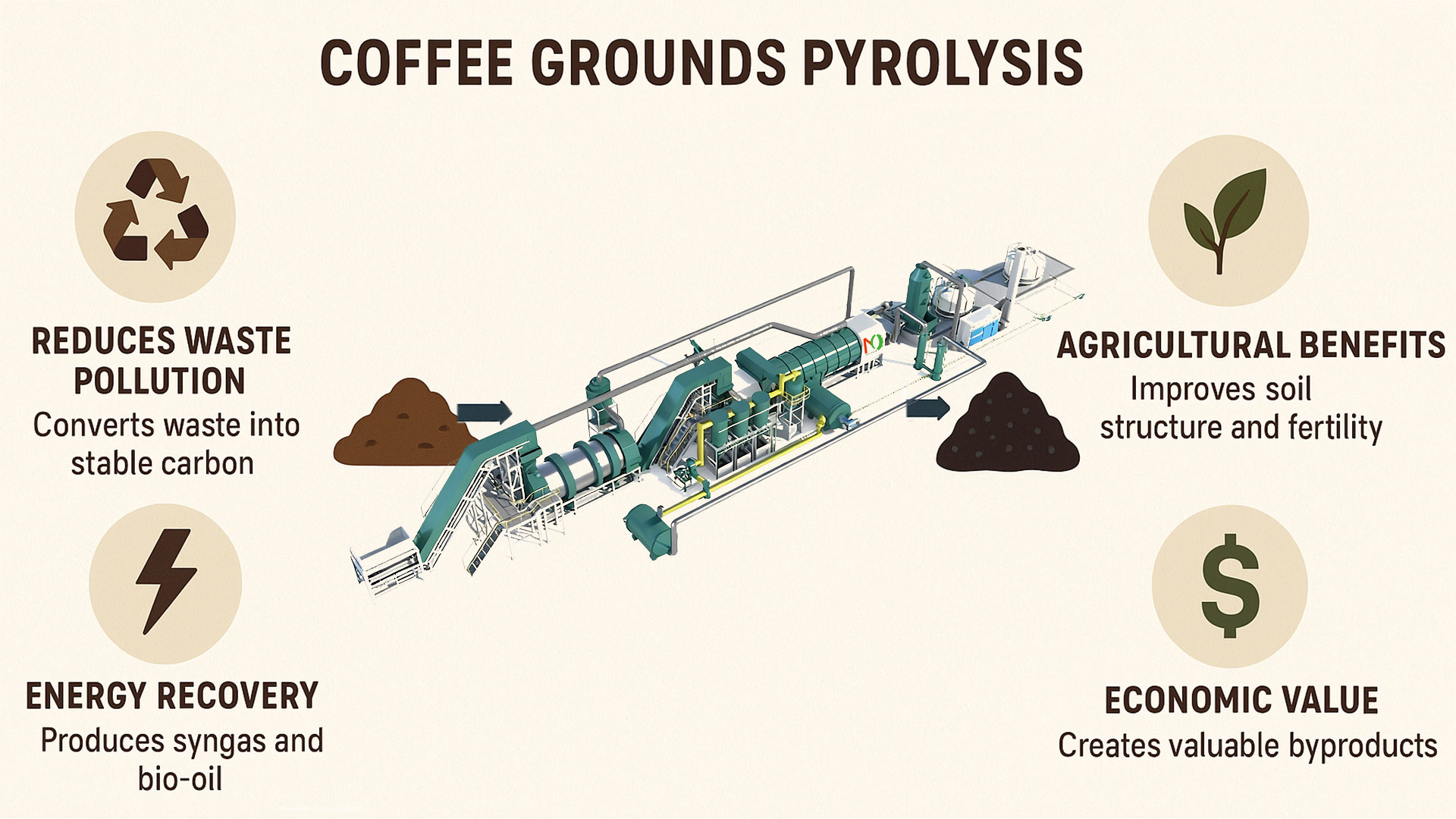

Advantages of Pyrolysis Coffee Grounds Waste Disposal

From a resource perspective, coffee grounds pyrolysis and carbonization have achieved a remarkable transformation from waste to a valuable resource. Coffee grounds are no longer useless trash, but have become a source of valuable biochar.

From an environmental perspective, pyrolysis technology for coffee grounds waste disposal is a powerful weapon for environmental protection. During pyrolysis and carbonization, the organic matter in coffee grounds decomposes under anaerobic or low-oxygen conditions. Most of the carbon is fixed in biochar, significantly reducing greenhouse gas emissions.

From an economic perspective, pyrolysis for coffee grounds waste disposal has created new economic growth points and driven industry development. Coffee grounds biochar has multiple uses, and revenue can be generated through its sale. The syngas and heat generated during pyrolysis and carbonization can be recovered and reused, providing partial energy support for the operation of the carbonization plant.