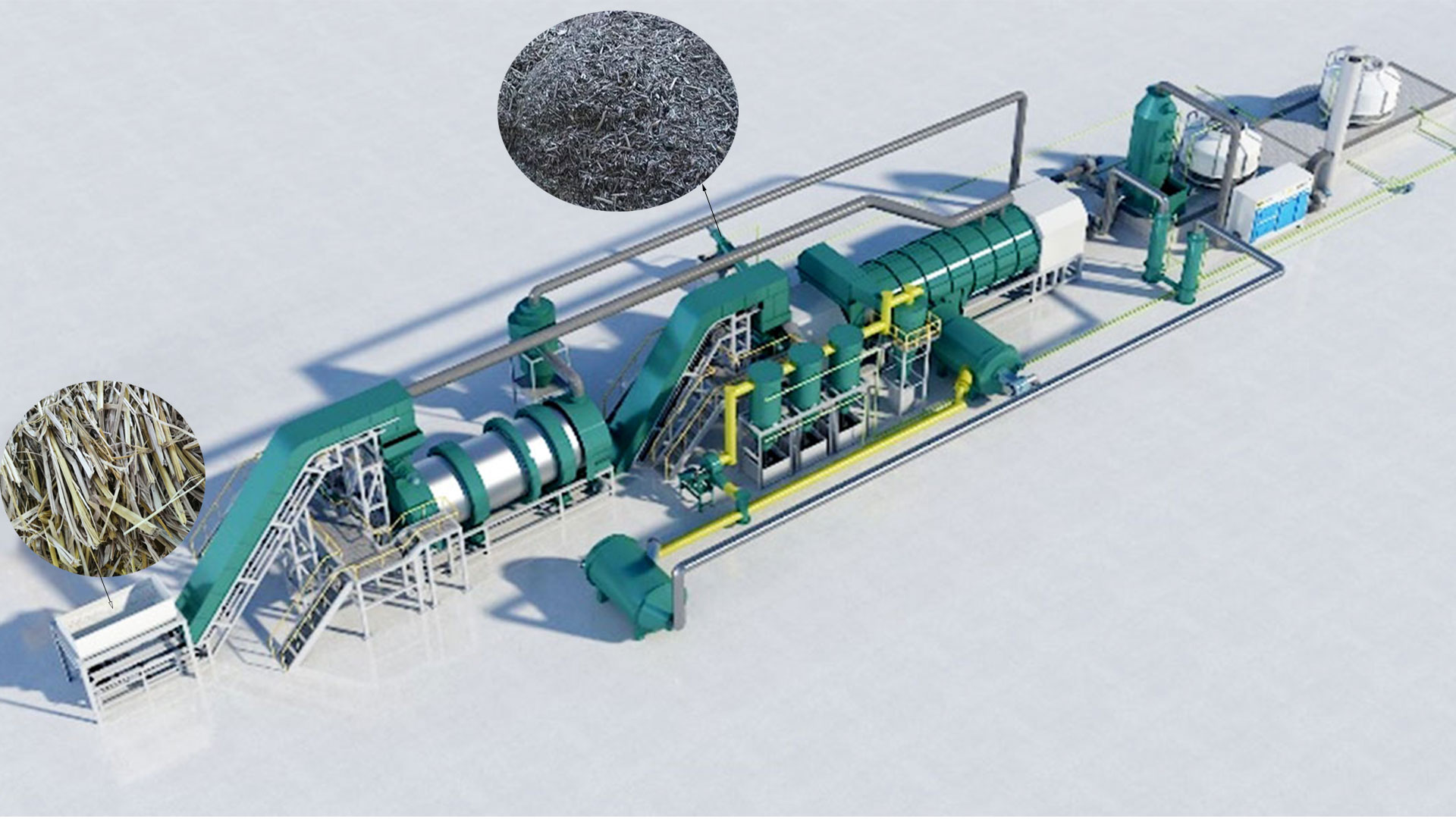

Straw biochar production equipment is key to converting straw into high-value biochar. It mainly includes several important systems: feeding system, pyrolysis carbonization reactor, biochar cooling and collection system, energy recovery system and exhaust treatment system.

Mingjie’s straw biochar production equipment employs a continuous pyrolysis carbonization process, enabling 24-hour uninterrupted operation. Raw materials are continuously fed from one end, moving within the furnace to complete the carbonization process, while char is continuously produced from the other end. This continuous operation significantly improves production efficiency, making it ideal for large-scale industrial production.

The continuous biomass pyrolysis equipment utilizes an intelligent temperature control system and a screw feed design. This not only precisely controls the temperature, ensuring the stability of straw biochar production, but also effectively reduces energy consumption.

Furthermore, the continuous pyrolysis equipment is equipped with an advanced automated control system that monitors key parameters such as temperature, pressure, and rotation speed in real time. It features alarm interlock functions, is easy to operate, and operates stably and reliably.

In addition, the continuous straw biochar production equipment utilizes advanced energy recovery technology to recover, purify, and recycle combustible gases such as carbon monoxide, methane, and oxygen generated during the carbonization process. This solves the environmental pollution problems caused by ordinary carbonization furnaces and provides heat energy for the equipment itself, achieving energy conservation and environmental protection.

Biomass pyrolysis equipment can produce various types of straw biochar, including rice straw biochar, wheat straw biochar, corn straw biochar, cotton straw biochar, soybean straw biochar, sugarcane bagasse biochar, and reed straw biochar.

Straw biochar production equipment combines pyrolysis technology with the concept of a circular economy. It not only solves the problem of straw disposal but also creates significant economic and ecological value. With the increasing demand for carbon neutrality and the expanding biochar market, the application prospects of biomass pyrolysis equipment will be even broader.

Factors Affecting Straw Biochar Production

Precise control of pyrolysis process parameters is crucial in determining the proportion and quality of pyrolysis products (biochar, bio-oil, and syngas). Straw biochar production is affected by parameters such as temperature, heating rate, and pyrolysis atmosphere.

Temperature

Straw pyrolysis is extremely sensitive to temperature. Low-temperature pyrolysis (300-500℃) more readily produces biochar with a well-developed porous structure, but yields lower bio-oil. Medium- to high-temperature pyrolysis (500-800℃) increases the yield of bio-oil and syngas, but reduces the fixed carbon content of the biochar.

In the continuous industrial straw biochar production, the temperature within the pyrolysis furnace is easily affected by factors such as feed rate, fuel supply, and airflow velocity.

When the feed rate suddenly increases, if the heat supply is not adjusted in time, the local temperature within the pyrolysis furnace will drop sharply. This results in the incomplete release of volatile gases, increasing biochar yield but significantly reducing adsorption capacity.

Conversely, if the feed rate slows down while heat is continuously supplied, the local temperature will rise sharply. This may lead to excessive decomposition of bio-oil into small molecule gases, reducing bio-oil yield. It also increases the proportion of carbon monoxide and hydrogen in the syngas.

Heating Rate

Rapid heating (>100℃/min) can shorten the residence time of straw in the pyrolysis furnace, improving production efficiency. It can also reduce secondary cracking of bio-oil, increasing bio-oil yield.

However, rapid heating requires the pyrolysis furnace to have efficient heat transfer capabilities. Uneven heating distribution in the pyrolysis equipment can lead to a large temperature difference between the surface and interior of the straw particles. This will trigger localized thermal stress, causing the straw particles to break and generating a large amount of dust. This dust not only enters subsequent systems with the syngas, clogging filters, but also reduces the particle integrity of biochar.

Slow heating (<10℃/min) ensures complete pyrolysis of straw and uniform biochar quality. However, it prolongs the production cycle, reduces the processing capacity of biochar production equipment, and increases the energy cost per unit product. Ultimately, this makes it difficult to meet the needs of large-scale industrial production.

Pyrolysis Atmosphere

Currently, most mainstream straw pyrolysis processes utilize inert atmospheres (such as nitrogen) or oxygen-deficient atmospheres. These atmospheres inhibit straw combustion and ensure the smooth progress of the pyrolysis reaction.

However, if the supply of inert gas is insufficient or the gas flow is uneven, localized oxygen-rich environments may occur within the pyrolysis furnace, leading to partial combustion of the straw. This not only consumes raw materials, but also reduces the carbon content of biochar and produces harmful gases (SO2, NOx).

Conversely, excessive inert gas supply will dilute the volatile gases produced during pyrolysis. This will reduce the concentration of bio-oil and syngas, increasing energy consumption for subsequent separation and purification. It will also increase the procurement cost of inert gas, weakening the project’s economic viability.