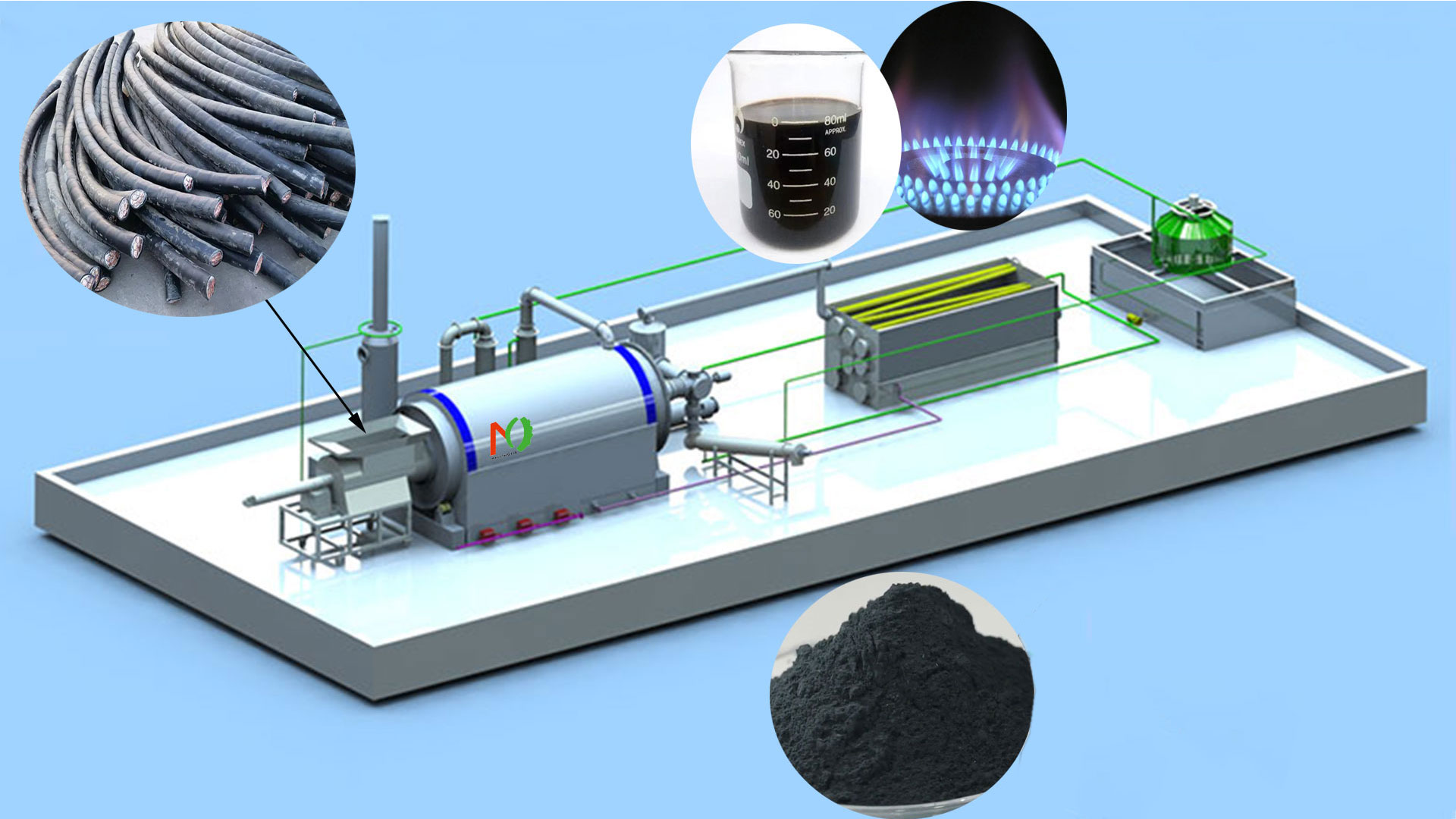

Pyrolysis of waste cable involves heating the cable insulation layer under anaerobic or oxygen-deficient conditions to cause thermal decomposition of the polymer molecules.

The pyrolysis of waste cable process occurs within a temperature range of 300-450℃ and lasts for 90-120 minutes. Within this temperature range, the carbon-carbon bonds in the plastic and rubber break, transforming into small-molecule hydrocarbons. The internal metallic conductors remain in a solid state.

Waste cables can be categorized by their use into power cables, communication cables, control cables, etc. The proportions of metallic and organic components vary among different types of cables. For example, low-voltage power cables typically have about 50% copper conductors and polyvinyl chloride (PVC) insulation. Communication cables, on the other hand, have about 40% copper conductors and often have polyethylene (PE) insulation.

Improper disposal of these organic insulation materials can become an environmental burden. Burning PVC releases hydrogen chloride (HCl) and dioxins, while PE takes decades to degrade naturally. Metal conductors, being a scarce resource, will result in significant resource waste if not efficiently recycled.

Pyrolysis of Waste Cable Advantages

High Metal Recovery Rate

The pyrolysis temperature of the organic insulation layer is much lower than the melting point of the metal. Within the pyrolysis range of 350-650℃, the metal conductor is completely unaffected. Furthermore, the insulation layer completely separates from the metal surface after pyrolysis, leaving no residue.

After waste pyrolysis, the purity of copper conductors in waste cables can reach over 99.9%, and the purity of aluminum conductors can reach over 99.5%. They can be directly used as raw materials for electrolytic copper and electrolytic aluminum. The metal recovery rate is consistently above 98%.

Organic Product Resource Utilization

The organic products generated from pyrolysis of waste cable have extremely high utilization value, forming a resource chain of “waste-energy-product”.

Pyrolysis gas, mainly composed of methane (20%-30%), ethylene (15%-25%), and hydrogen (5%-10%), has a calorific value of 20-30 MJ/m³. It can be directly used as fuel for the pyrolysis reactor, providing energy for the operation of the pyrolysis equipment and achieving energy recovery.

Pyrolysis oil, mainly composed of alkanes and olefins, has a calorific value of 42-45 MJ/kg and can be used as fuel for industrial boilers or refined into diesel fuel substitutes.

Solid carbon black can be used as an adsorbent for wastewater treatment.

Harmless Treatment

Pyrolysis of waste cable technology avoids the pollution problems of traditional treatment methods at the source, and the anaerobic environment completely eliminates the formation of dioxins. The metal residue produced after pyrolysis contains no organic pollutants and can be directly incorporated into the metal recovery system. Liquid oil and pyrolysis gas are both recovered and reused, with no wastewater or waste residue discharged, achieving near-zero pollution treatment.

Pyrolysis Waste Cable into Fuel Oil Process

Pre-treatment: Waste wires and cables require stripping and sorting before recycling. They are processed according to their material composition; copper, electrical components, and connectors can be sold or reprocessed. The wire and cable sheaths are crushed, screened, and drained of moisture to remove impurities.

Pyrolysis: After pre-treatment, the waste wire and cable sheaths are fed into the pyrolysis reactor. As the temperature rises and the furnace rotates steadily, oil and gas are steadily produced. The produced oil and gas enter a buffer tank to reduce the flow rate and simultaneously settle carbon black impurities, facilitating the next condensation stage.

Condensation: The oil and gas produced by pyrolysis of waste cable are condensed into liquid fuel oil through a condenser and condensation tower system under the action of circulating cooling water. The fuel oil is stored in oil tanks.

Purification: The pyrolysis of waste cable process generates waste gas and residue. Therefore, the pyrolysis equipment is equipped with environmental protection devices such as desulfurization towers and carbon black conveying and collection systems to treat these wastes, thus promoting green and environmentally friendly oil refining.