The core of the The plastic to fuel machine converts mixed plastics into pyrolysis oil, syngas, and carbon black in an oxygen-free environment. One ton of plastic can produce 700 liters of diesel fuel, with carbon emissions 60% lower than fossil fuels., which converts waste into energy, lies in pyrolysis technology. The aim is to utilize low-value waste plastics, marine plastic waste, and medical plastic waste, including single PP/PE/PS/ABS or mixed plastics.

Pyrolysis machine has effectively overcome many key challenges in plastic pyrolysis processes, such as coking, feeding and sealing difficulties, and product polymerization. It ensures high-quality pyrolysis products by precisely controlling the pyrolysis temperature and reaction time.

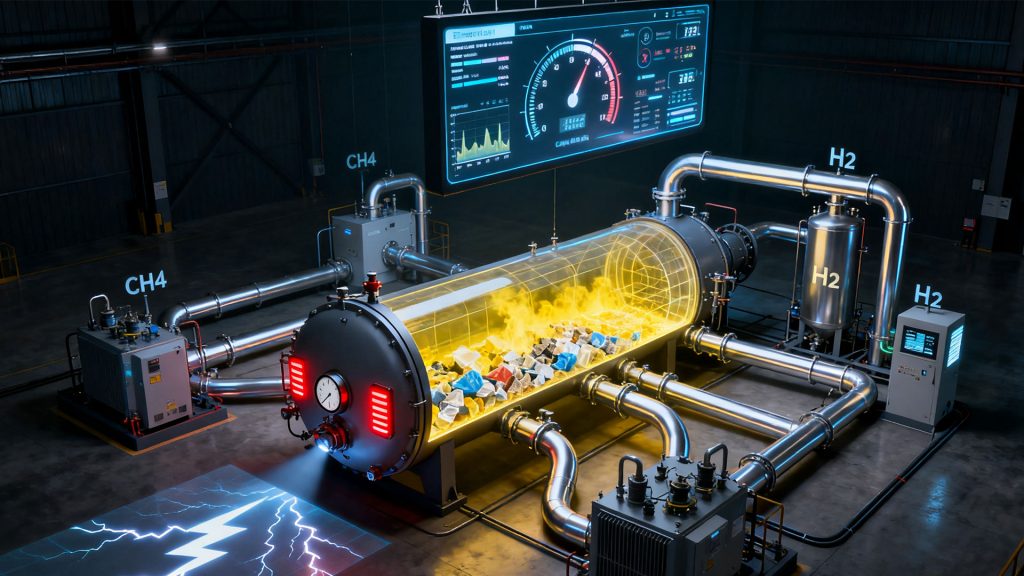

To ensure uniform heating during subsequent processes, the plastic is crushed or cut into small pieces. The pre-treated plastic enters the plastic into fuel machine, the central site of the pyrolysis reaction. In an oxygen-free or low-oxygen environment, the furnace begins heating the plastic.

This continues until the critical pyrolysis temperature range of 400°C – 600°C is reached. At this high temperature, the originally stable polymer molecular chains in the plastic begin to break down. The large molecular structure in the plastic gradually decomposes, forming a series of smaller molecules, producing gaseous and liquid hydrocarbons.

After pyrolysis, the plastic pyrolysis machine produces an oil-gas mixture. This mixture is introduced into a condenser, where it forms fuel oil. The condensed oil is stored in tanks. Simultaneously, some non-condensable gases, such as hydrogen, methane, and carbon dioxide, are also produced. These gases can be further processed and converted into energy, such as as auxiliary fuel in the pyrolysis process, achieving energy recycling.

Since the plastic to fuel machine produces crude oil, it requires fine separation using pyrolysis oil distillation equipment. Distillation separates the oils based on their boiling points, ultimately yielding fuel oils of different qualities suitable for various applications.

The solid residues left after pyrolysis, such as carbon black, are rich in carbon. They can be used as industrial raw materials in rubber manufacturing, ink production, and other fields.

Applications of Plastic to Fuel Pyrolysis Projects

Plastic to Fuel machines are widely used in plastic pyrolysis projects worldwide and have entered the commercialization stage.

- As Transportation Fuel: This is the most direct application of plastic pyrolysis oil. After further refining, plastic pyrolysis oil (PPO) can be used directly as fuel, such as gasoline, diesel, and aviation kerosene, or blended with existing fuels.

- Engine Applications: Research shows that mixing a certain proportion of plastic pyrolysis oil with diesel can be used directly in diesel engines. This can improve some combustion performance and potentially reduce some emissions.

- As Industrial Fuel or Feedstock: Syngas produced from plastic conversion can be used as energy or chemical feedstock in industrial fields.

- Fuel and Energy: Non-condensable gases produced by pyrolysis can be used to heat the reactor itself, achieving an energy cycle. Besides generating electricity, it can also be used as industrial fuel.

- Chemical Feedstock: Naphtha produced by pyrolysis can be used as a feedstock for petrochemical companies to produce new plastics, achieving a closed loop.

Plastic to Fuel Machine for Sustainable Development

The plastic to fuel machine converts mixed plastics into pyrolysis oil, syngas, and carbon black in an oxygen-free environment. One ton of plastic can produce 700 liters of diesel fuel, with carbon emissions 60% lower than fossil fuels.

Environmental protection is at the core of plastic to fuel machine, directly contributing to reduced plastic pollution and landfill burden, and mitigating the risk of microplastic pollution. This is crucial for protecting marine biodiversity and soil health.

Plastic fuel oil have a carbon footprint 60-80% lower than traditional fossil fuels. This is because they recycle carbon stored in plastic waste, rather than extracting new fossil carbon.

PTF fuels serve as a bridge between waste management and energy transition. The resulting syngas can power the plastic to fuel machine itself or replace coal-fired power generation.

The plastic to fuel machine not only produces fuel but also carbon black and combustible gas. This “waste-to-resource” model achieves material recycling, aligning with the principles of a circular economy. The carbon black produced by the plastic to fuel process reduces the demand for virgin carbon black, saving 1.5 tons of crude oil for every ton of carbon black produced.