In early December 2025, the MJT-2000 sawdust biochar machine successfully commenced operation in Saudi Arabia. At the client’s site, this biochar production equipment demonstrated an astonishingly efficient and stable output capacity. It has been running continuously and stably for several hours, fully showcasing its excellent stability and reliability.

The client highly praised the performance of the sawdust biochar machine. These evaluations are not only an affirmation of the equipment and technology but also an expression of their expectations for future cooperation. We will continue to strive to optimize our technology and services, providing customers with higher-quality products and solutions.

Sawdust Biochar Machine Commissioning

After the biomass pyrolysis plant is installed, every step of the equipment commissioning process is crucial. It affects the stable operation of the entire wood biochar production system.

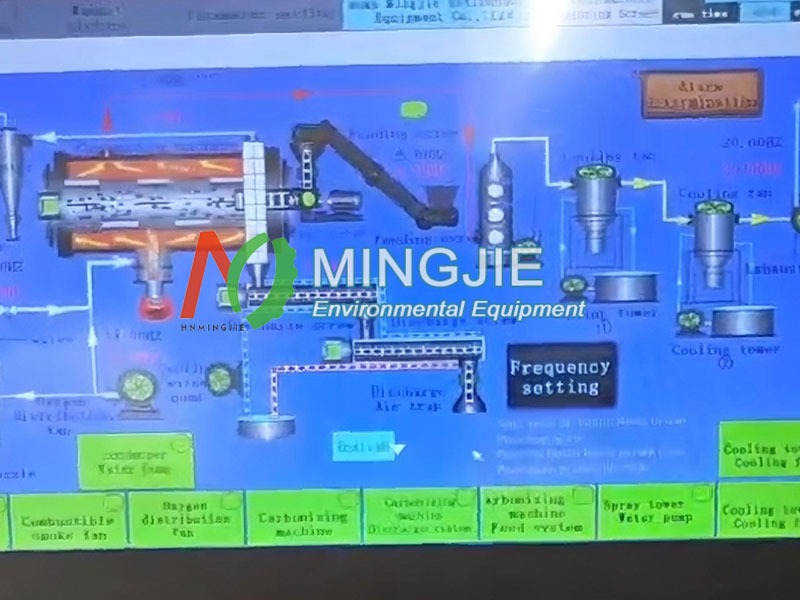

During the commissioning of the biomass to biochar production line, technicians conduct coordinated testing of various systems, including the feeding system, pyrolysis system, cooling system, and exhaust gas treatment system. This ensures that they work together seamlessly to achieve efficient production.

During the operation of the sawdust biochar machine, it is crucial to ensure the smooth transfer of materials between the various systems. It is also essential to maintain an oxygen-free environment in the pyrolysis equipment, ensure reasonable heat transfer and utilization, and verify that the exhaust gas treatment meets environmental standards.

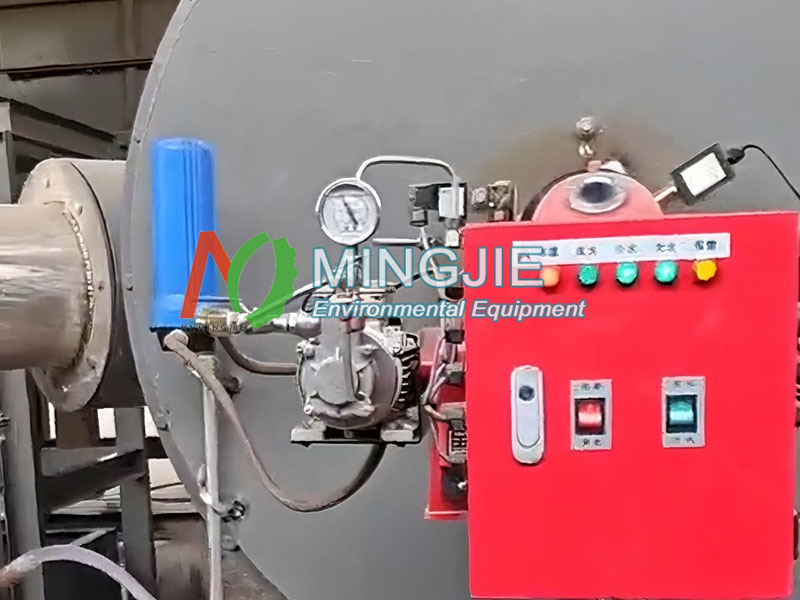

Only through comprehensive and meticulous commissioning can the biomass pyrolysis equipment reliably and efficiently produce sawdust biochar. The biochar production process requires precise control of key parameters, such as temperature and pressure.

Temperature Control of Wood Biochar Equipment

In the sawdust biochar production process, temperature is one of the core factors affecting product quality and production efficiency.

Excessively high pyrolysis temperatures can lead to excessive cracking of the biochar, reducing product quality. Conversely, excessively low temperatures will result in incomplete pyrolysis reactions, affecting production efficiency. Therefore, technicians use the temperature control system on the equipment to precisely control the pyrolysis temperature within the set range, with the error controlled within a very small range.

Pressure Control of Pyrolysis Equipment

At the same time, pressure control is also crucial. Excessively high pressure may pose safety hazards to the equipment, while excessively low pressure will affect material transport and the pyrolysis reaction. Technicians adjust the pressure parameters in real time based on the equipment’s operating conditions and process requirements.

Professional Biomass Pyrolysis Equipment Manufacturer

MJT-2000 sawdust biochar machine utilizes advanced continuous pyrolysis technology and an intelligent control system. In an oxygen-free or low-oxygen environment, it transforms waste sawdust into biochar of immense value.

The process involves heating the sawdust to a specific temperature using an external heat source under oxygen-free or low-oxygen conditions, causing thermochemical reactions in the organic matter. During this biomass pyrolysis process, the large organic molecules in sawdust gradually decompose, undergoing complex reactions (cracking and condensation). Ultimately, the sawdust is converted into combustible gas, liquid oil, and solid biochar.

Intelligent Control System

The sawdust biochar machine is equipped with an intelligent control system. This system provides comprehensive and precise control over the entire production process, ensuring high efficiency, stability, and safety. Sensors distributed throughout the sawdust biochar machine collect key parameters, such as temperature, pressure, and material flow rate in real time. This data is then quickly transmitted to the central processor for analysis and processing.

In terms of temperature control, the intelligent control system accurately adjusts the power of the heating device according to the preset pyrolysis temperature curve. This keeps the pyrolysis temperature within an extremely precise range with controllable error.

The intelligent control system also excels in pressure monitoring and control. It can monitor internal pressure changes in the equipment in real time. The system automatically adjusts the material conveying speed and flow rate based on pressure changes, so as to maintain stable internal pressure.