Recently, four sets of MJ-15 pyrolysis equipments were loaded onto a ship at a Chinese port and set sail for Argentina. After several days of road transport, the convoy successfully arrived at the port. Here, the four sets of pyrolysis equipments will be transferred from road transport to sea transport, embarking on a longer transoceanic journey.

The 4 sets pyrolysis equipments are expected to arrive at a designated port in Argentina in a few weeks. Following this, Mingjie engineers will provide guidance on installation, commissioning, and personnel training at the pyrolysis plant, ensuring the successful implementation of the waste-to-oil project.

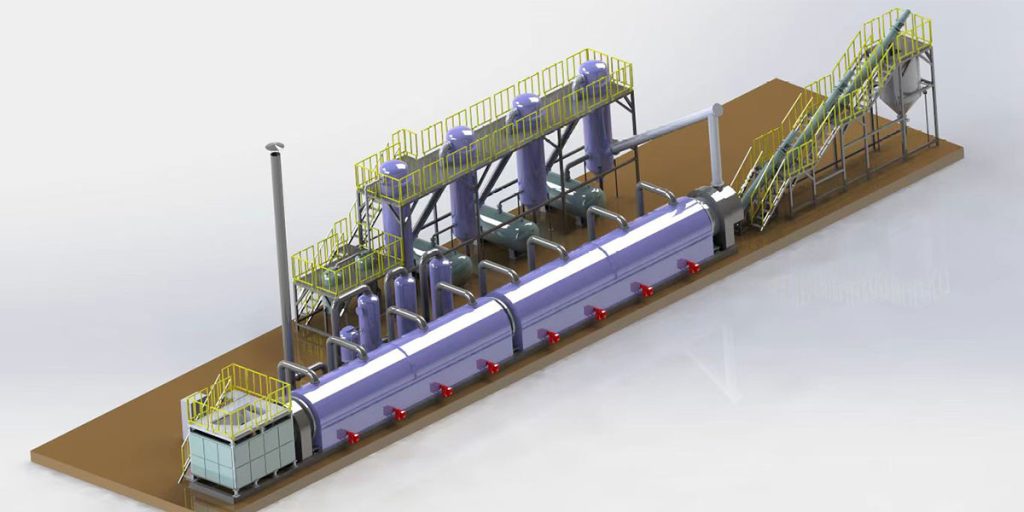

The client adopted a customized waste pyrolysis treatment solution. This pyrolysis solution efficiently and stably converts various organic solid wastes into high-value-added fuel oil, combustible gas, and carbon black products. The entire system integrates intelligent control, heat recovery, and exhaust gas purification modules. It ensures resource regeneration while meeting stringent environmental emission standards.

Pyrolysis Equipments for Environmental Protection

The commissioning of 4 sets pyrolysis equipments will have a positive and far-reaching impact on environmental protection in Argentina. They will effectively enhance Argentina’s waste treatment capacity. The pyrolysis equipments will convert large amounts of organic waste into usable energy and resources. This will reduce environmental pollution and alleviate the pressure on landfills and incinerators.

Furthermore, the operation of the pyrolysis equipments will stimulate the development of related industries and create more job opportunities. This is not merely a delivery of equipment, but a successful example of international environmental cooperation, contributing to the development of global environmental protection.

Pyrolysis Plant Manufacturer for Solution Customization

Mingjie Group is a professional pyrolysis equipment manufacturer, and we can provide customized pyrolysis solutions for our clients. This will maximize profits for waste treatment and resource recycling.

The core of customized pyrolysis solutions lies in their ability to deeply align with the unique needs of clients. In the waste treatment field, different clients face diverse waste types, ranging from industrial waste residue, waste plastics, and waste rubber to municipal solid waste, medical waste, agricultural and forestry waste, and livestock manure.

Furthermore, the scale of waste varies significantly. Large industrial enterprises may generate tens or even hundreds of tons of waste, while small commercial sites generate relatively smaller quantities.

Customized Solutions Based on Raw Materials

Faced with such complex and diverse situations, generic pyrolysis solutions often fail to achieve ideal results. Our customized pyrolysis solutions involve a comprehensive and detailed analysis of the client’s waste from the outset.

This includes a thorough understanding of the waste’s chemical composition, physical properties, moisture content, calorific value, and other key parameters. Simultaneously, we fully consider the client’s processing scale, site conditions, and expected goals.

For companies processing large quantities of waste plastics, customized solutions focus on maximizing the pyrolysis conversion rate. We select suitable pyrolysis equipments and process conditions for plastic pyrolysis to ensure efficient conversion of waste plastic into fuel oil.

High-Efficiency and Energy-Saving Design

High-efficiency and energy-saving design is undoubtedly a major highlight of customized pyrolysis solutions. We help our clients treat waste while minimizing energy consumption and operating costs.

From an energy utilization perspective, customized pyrolysis solutions employ a range of advanced technologies and strategies to achieve efficient energy conversion and recycling. Continuous pyrolysis equipment can effectively recover waste heat and syngas from the pyrolysis process to improve energy utilization.

Environmental Compliance Guarantee

In today’s increasingly stringent environmental regulations, environmental issues in waste treatment have become one of the most pressing concerns for our clients. Customized pyrolysis equipments help clients easily solve environmental challenges in waste treatment, ensuring that their production and operations comply with environmental regulations.

From the selection of the pyrolysis process to the configuration of equipment, every step fully considers the environmental impact and implements a series of effective environmental protection measures.

During the pyrolysis process, the generation of harmful gases is suppressed by precisely controlling reaction conditions, such as pyrolysis temperature and oxygen content. Simultaneously, advanced flue gas purification technologies are adopted, such as desulfurization, denitrification, and dust removal. This allows for deep treatment of the flue gas generated from pyrolysis, ensuring that emissions meet national and local environmental standards.