Globally, the market for waste tyre processing is vast and growing. Market research reports indicate that the global waste tire processing market is expected to grow from approximately $15 billion in 2020 to approximately $20 billion by 2025. Pyrolysis of waste tyre, as a promising thermochemical conversion method, demonstrates unique environmental advantages. Increasingly stringent environmental regulations, with many countries requiring tire manufacturers to take responsibility for recycling, are also contributing to this growth.

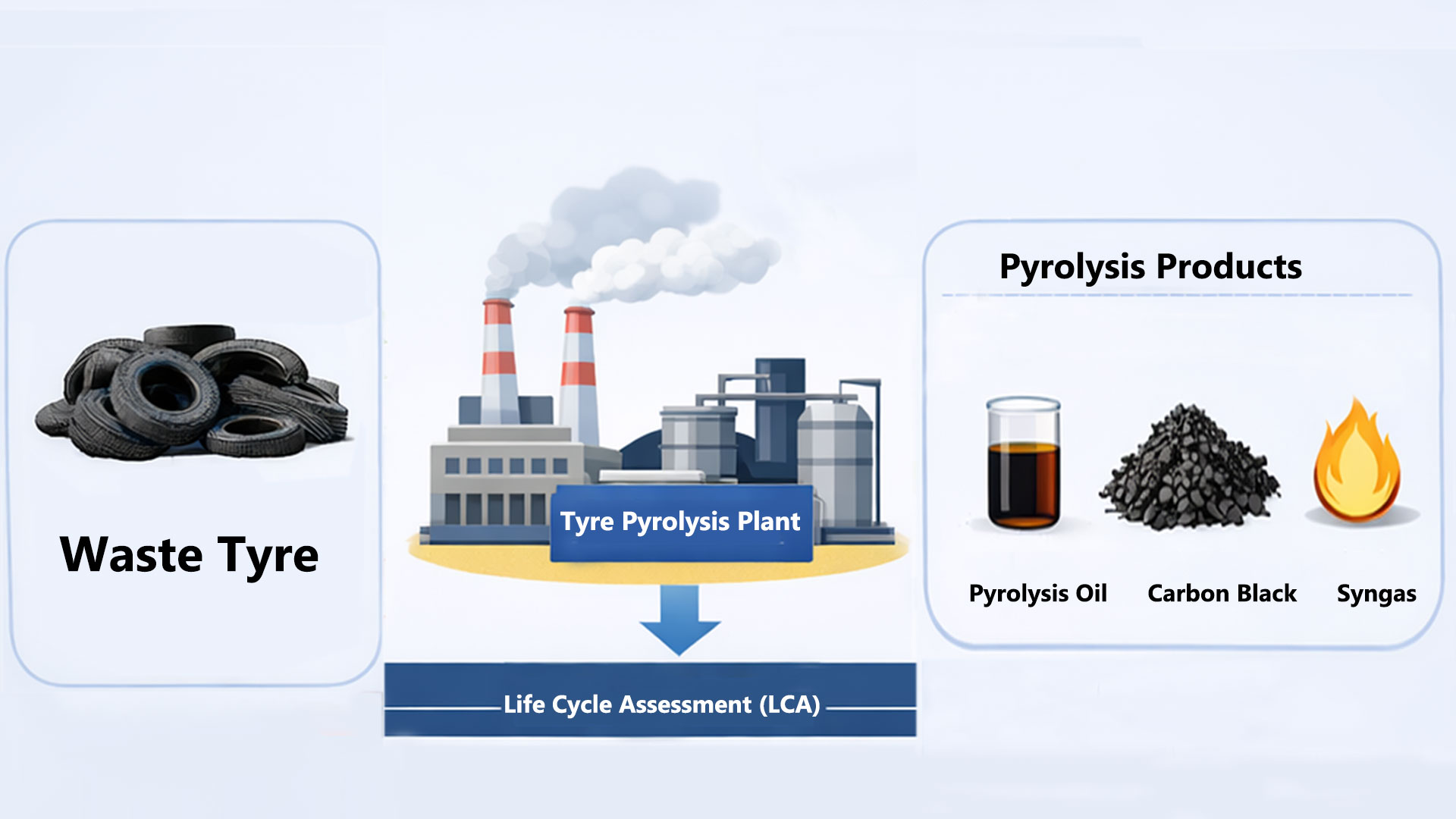

Pyrolysis technology, by heating and decomposing waste tires in an oxygen-deficient environment, can simultaneously obtain four main products: pyrolysis oil, carbon black, steel wire, and pyrolysis gas. The waste tyre pyrolysis plant can enable comprehensive resource recovery and utilization.

How Tyre Pyrolysis Achieves Carbon Emission Reduction

The carbon emission reduction potential of waste tyre pyrolysis is mainly realized through two pathways: material substitution and energy self-sufficiency.

- The pyrolysis oil has a calorific value comparable to diesel fuel, and each kilogram can replace traditional diesel fuel, reducing carbon dioxide emissions by 2.7-3.2 kg. It also has the potential to become a raw material for sustainable aviation fuel.

- After modification, the recovered carbon black can replace virgin carbon black, reducing carbon emissions by 1.8-2.2 tons per ton.

- The pyrolysis gas has a calorific value of 30-40 MJ/m³, which can meet more than 95% of the energy needs of the pyrolysis process. Continuous pyrolysis plants can form a closed-loop system for energy self-sufficiency.

Transforming emission reduction potential into market-recognized “carbon assets” requires scientific accounting.

Life Cycle Assessment (LCA): This is the cornerstone for quantifying emission reduction benefits. Only through scientific calculation using LCA can the true emission reductions of tyre pyrolysis products compared to traditional methods be proven, thus enabling the application for carbon credits.

Pyrolysis of Waste Tyre Projects in the World

Globally, countries are implementing policies and regulations to encourage the pyrolysis of waste tyre.

North America is driven by a dual approach of policy subsidies and technological advancement. The United States provides specific subsidies for pyrolysis of waste tyre projects through the Infrastructure Investment and Jobs Act. Canada focuses on differentiated technological development, encouraging the research and development of low-temperature pyrolysis technology through policy incentives.

The European region centers its policies on strict mandatory recycling systems and circular economy goals. The EU Circular Economy Action Plan (CEAP) explicitly requires a tire recycling rate of 95% by 2030. Simultaneously, the strict limitations on polycyclic aromatic hydrocarbons (PAHs) content under the REACH regulation have created a vast market for pyrolytic carbon black (PCB).

Germany’s Pyrum Innovations boasts a capacity utilization rate exceeding 80% for its continuous pyrolysis of waste tyre process. Spain Black Bear Carbon’s plant in the Netherlands processes 60,000 tons of waste tires annually, and its products have successfully obtained certification from giants like Michelin and Continental Tires. France, through its “Waste Tire Recycling and Environmental Protection Association,” coordinates industry resources and complements government mandatory recycling regulations. It clearly defines manufacturers’ recycling responsibilities based solely on tonnage, regardless of brand, providing a stable supply of raw materials for pyrolysis of waste tyre projects.

The Asian region exhibits a tiered approach to policy implementation. The Chinese government places great importance on waste tire recycling and comprehensively promotes the development of the waste tyre pyrolysis industry. India uses policy guidance to increase tyre recycling rates, driving rapid growth in the pyrolysis market, with an annual capacity reaching 150,000 tons. Southeast Asian countries such as Thailand and Malaysia are leveraging foreign investment cooperation policies to attract international capital for the construction of pyrolysis plants, primarily to meet the needs of their local rubber industry supply chains.

The implementation of these policies and regulations reflects the importance that countries place on environmental protection and resource recycling. It also provides strong policy support and guarantees for the development of the pyrolysis of waste tyre industry. This has increased the recycling rate of waste tires, reduced environmental pollution, and achieved a win-win situation for both economic and environmental benefits.