In the waste plastic into fuel machine market, continuous pyrolysis machines hold a significant market share. The high efficiency and scalability makes them the preferred choice for large-scale plastic pyrolysis projects. Batch pyrolysis machines, due to their flexibility and lower investment costs, are attractive for smaller operations and pilot projects.

As the waste plastic into fuel machine market grows, continuous pyrolysis machines maintain their dominance due to their ability to handle larger volumes of continuous feedstock processing. They are characterized by their ability to process a steady waste stream, thereby improving operational efficiency and reducing labor costs. Continuous pyrolysis plant is suitable for industrial applications, where consistent output is crucial for profitability.

Global Applications of Waste Plastic into Fuel Machines

North America

North America is the largest market for plastic waste pyrolysis oil, accounting for approximately 45% of the global market share. Growth in this region is driven by stringent environmental regulations and the increasing demand for sustainable waste management solutions. Plastic pyrolysis plants aim to reduce plastic waste and promote a circular economy.

The United States and Canada are leading countries in this market, with companies at the forefront of pyrolysis technology. Continuous pyrolysis plants are focused on improving the efficiency and reducing the costs of plastic pyrolysis projects.

Europe

Europe is the second largest market for plastic waste pyrolysis oil, accounting for approximately 30% of the global market share. Growth in this region is driven by EU regulations aimed at reducing plastic waste and promoting recycling. Waste plastic to fuel pyrolysis plant play a crucial role in driving sustainable technologies.

Asia Pacific

The Asia Pacific market for plastic waste pyrolysis oil is growing rapidly, accounting for approximately 20% of the global market share. Growth in this region is driven by accelerated urbanization, increased plastic consumption, and growing emphasis on waste management solutions. Diverse waste management needs create significant opportunities for the waste plastic into fuel machine market.

Middle East and Africa

The Middle East and Africa region is emerging as a potential market for plastic waste pyrolysis oil, currently accounting for approximately 5% of the global market share. Growth is driven by increasing awareness of environmental issues and the demand for sustainable waste management solutions. They are beginning to recognize the economic benefits of converting plastic waste into valuable resources, which is fueling interest in waste plastic into fuel machines.

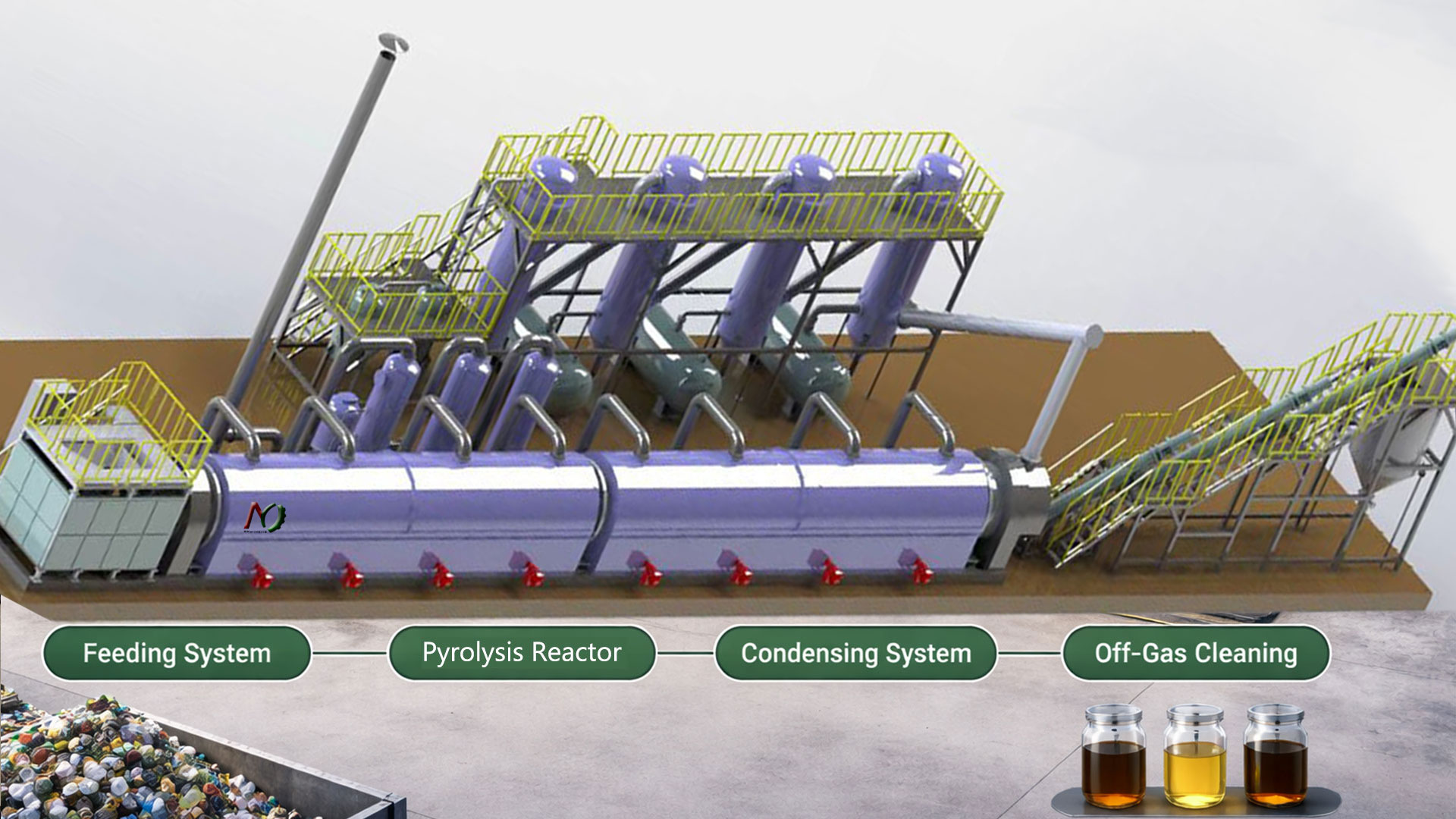

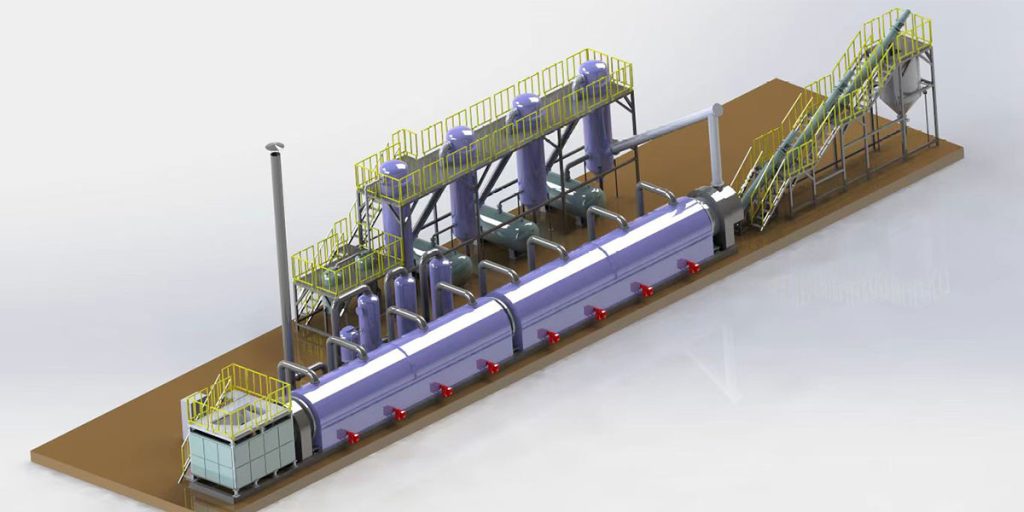

How Continuous Pyrolysis Plant Converts Plastics into Fuel?

The continuous plastic pyrolysis plant achieves the conversion of waste plastics into fuel through an integrated process design, precise automatic control, and internal energy recycling. The entire process can be divided into the following three stages.

Raw Material Pre-treatment and Sealed Feeding

The waste plastic first undergoes rigorous pre-treatment, which is crucial for ensuring continuous and stable operation. This typically includes crushing to smaller sizes and drying to remove moisture. Subsequently, the material is continuously and uniformly fed into the reactor through devices such as screw feeders. The complete sealing of the feeding system is essential. It ensures that external oxygen cannot enter, maintaining an oxygen-free environment within the pyrolysis reactor.

Continuous Pyrolysis Reaction and Product Separation

In the continuous pyrolysis reactor, the plastic is indirectly heated to approximately 400-450°C in an oxygen-free or oxygen-deficient environment. Under high temperature, the long-chain polymers of the plastic break down, producing a mixture of oil and gas.

Oil and Gas Treatment: The mixed oil and gas are extracted under slight negative pressure. They first pass through devices such as gas separators to remove dust, and then enter a condensation system for cooling. The liquefiable portion becomes pyrolysis oil and is collected in tanks. The non-condensable combustible gas (mainly methane and hydrogen) enters the purification system.

Solid Residue Treatment: The remaining solid residue after the reaction (mainly carbon black) is continuously discharged through a water-cooled screw conveyor and a sealed slag discharge system. The entire process takes place in fully enclosed pipelines to prevent dust leakage.

Energy Recovery and Environmental Treatment

Energy Self-sufficiency: The purified non-condensable combustible gas is returned to the combustion chamber of the reactor as heating fuel. This meets the thermal energy needs of the continuous pyrolysis reactor itself, significantly reducing external fuel consumption and operating costs.

Emission Control: The flue gas generated by plastic pyrolysis and the tail gas after the combustion of non-condensable gas are treated by a rigorous environmental protection system (such as spray towers, activated carbon adsorption). This ensures that particulate matter, acidic gases, and other pollutants meet emission standards before discharge.