In early February 2026, Mingjie Group dispatched engineers to install the MJZ-20 crude oil distillation plant for sale to Malaysia. The distillation equipment is suitable for the rectification and purification of tire and plastic pyrolysis crude oil, waste engine oil, and waste lubricating oil.

This distillation process uses a high-vacuum environment to perform vacuum distillation of crude oil, producing high-quality fuel oil. It can improve the market applications of pyrolysis oil.

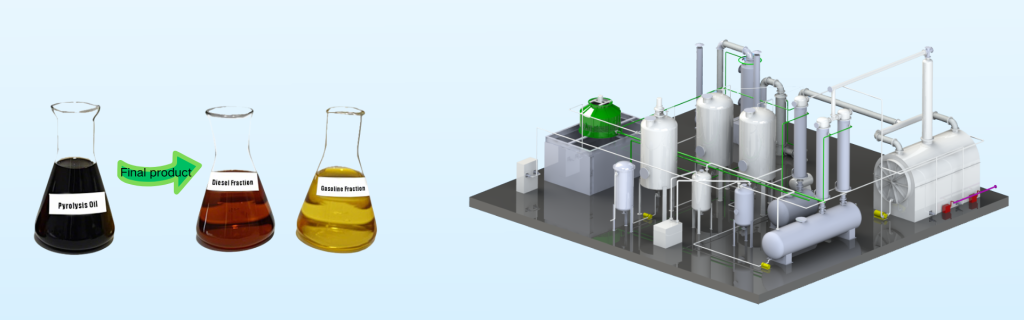

Why is Pyrolysis Oil Considered Crude Oil? Pyrolysis oil is a direct byproduct of pyrolysis plants. It typically refers to oil produced from waste tires and waste plastics through catalytic or high-temperature pyrolysis. Pyrolysis oil undergoes no further processing and is a black or dark brown viscous liquid. This is because it contains many impurities, has a complex composition, and poor stability.

Pyrolysis oil distillation plant is a core supporting equipment in the solid waste pyrolysis industry. It is mainly used for fractionation and purification of crude pyrolysis oil, separating light fuel oil, heavy fuel oil, and chemical raw materials. It directly determines the added value and market competitiveness of the pyrolysis oil.

Principle of Crude Oil Distillation Plant

The crude oil distillation plant adopts high-vacuum negative pressure distillation technology. It achieves liquid-liquid separation based on the difference in the mean free path of molecular motion between different substances. The mean free path of molecular motion refers to the distance a molecule travels between two adjacent collisions.

When the oil is heated, lighter and heavier molecules overflow the liquid surface and enter the gas phase. Due to the different mean free paths of the lighter and heavier molecules, they travel different distances after overflowing. This achieves the purpose of substance separation.

Negative pressure distillation technology accelerates the molecule overflow time, and also increases the oil yield. It ultimately produces non-standard diesel fuel, which can be used as industrial fuel or diesel engine fuel.

Installation Process of Crude Oil Distillation Plant

The installation process of crude oil distillation plant must strictly follow standardized procedures and control every critical step. This is essential to ensure the long-term stable, safe, and efficient operation of the distillation equipment.

Pre-installation Preparations

Preliminary preparations for installing the crude oil distillation plant include ensuring the site is suitable and the equipment is in good working order. This directly affects subsequent installation efficiency and equipment operational stability.

Select a flat, firm, and well-ventilated site, away from flammable and explosive materials. The site surface must be waterproofed to prevent pyrolysis oil leaks from contaminating the soil. Lay power lines and pipelines, etc.

Core Installation Steps

The core principle of installing pyrolysis oil distillation equipment is to proceed with heavy-duty equipment before light-duty equipment, and to install the main structure before auxiliary equipment. Key control points include the installation of the distillation tower, piping connections, and sealing performance.

Pipeline connections are a critical step in the installation of pyrolysis oil distillation plant, directly affecting the equipment’s sealing performance and operational safety.

Electrical and Control System Installation

The electrical and control system is the brain of the used oil distillation plant. It is responsible for controlling and monitoring parameters such as equipment start-up and shutdown, temperature, pressure, and flow. Installation must ensure standardized wiring and stable signals to prevent electrical faults from affecting equipment operation.

Auxiliary System Assembly

Heating System: If gas heating is used, connect the gas pipeline, ensuring a tight seal and stable gas supply. If electric heating is used, install the heating element and connect the heating circuit. Test the heating effect of the heating element to ensure temperature controllability.

Cooling System: Connect the cooling water pipeline to the condenser, ensuring a smooth cooling water supply.

Safety Protection System: Install safety valves, pressure gauges, thermometers, etc. Ensure adequate safety protection during equipment operation.

After the crude oil distillation plant is installed, it needs to undergo phased commissioning, from no-load to load testing. Only after successful commissioning can it be put into formal production.