Aluminum plastic composites are typically made by tightly bonding polyethylene (PE) or polypropylene (PP) plastic film with aluminum foil using adhesives. This strong bond is a nightmare for traditional recycling processes. Aluminum plastic pyrolysis, as a more efficient and environmentally friendly resource recovery technology, is gradually becoming a solution for solid waste.

Pyrolysis technology, as an efficient method for treating aluminum plastic waste, is based on a thermochemical conversion process. The pyrolysis equipment heats the aluminum plastic materials in a specific environment with no or limited oxygen supply. During heating, the high molecular weight polymers in the aluminum plastic materials undergo chemical bond breakage, degrading into low-molecular-weight or small-molecule compounds.

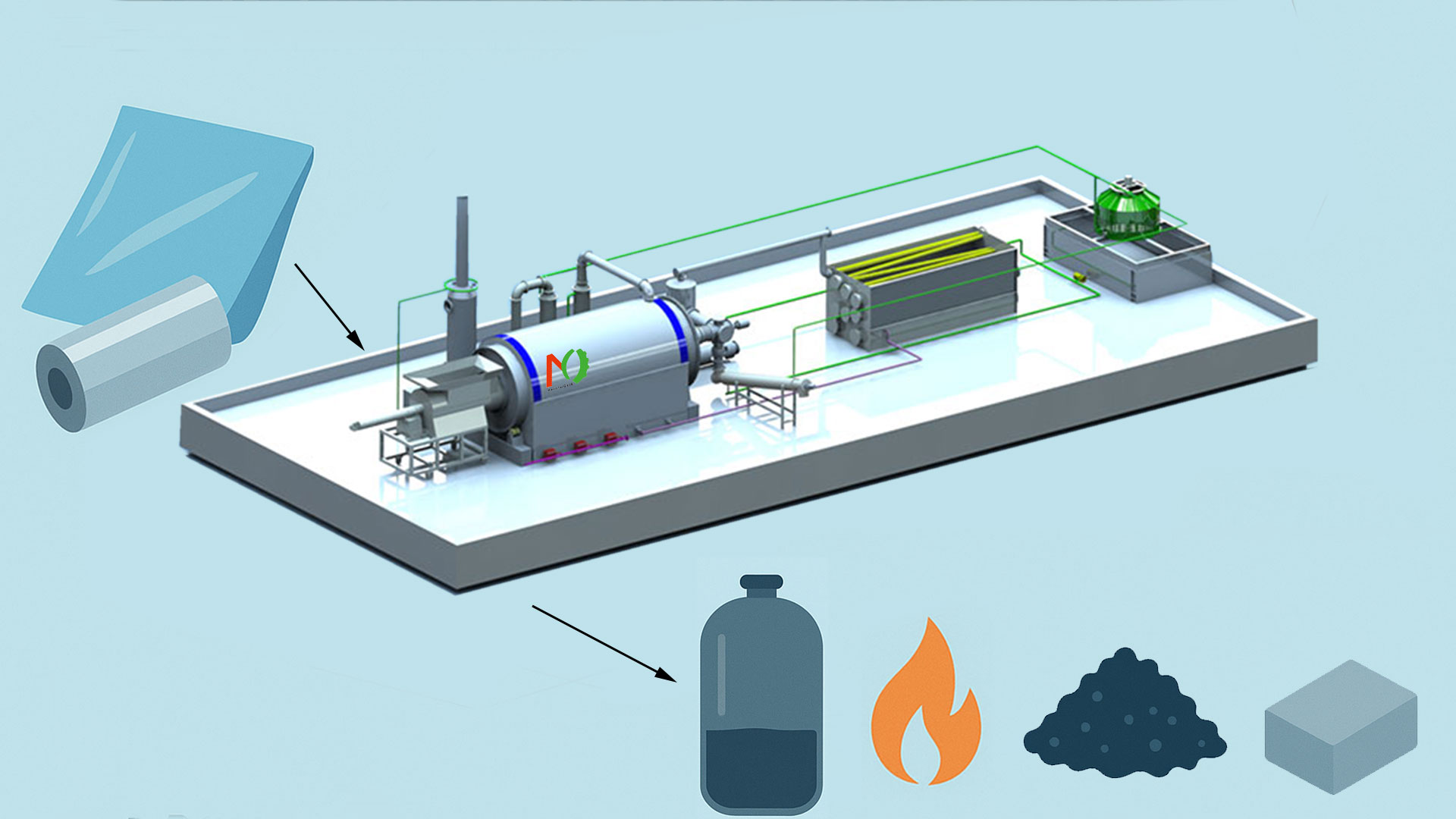

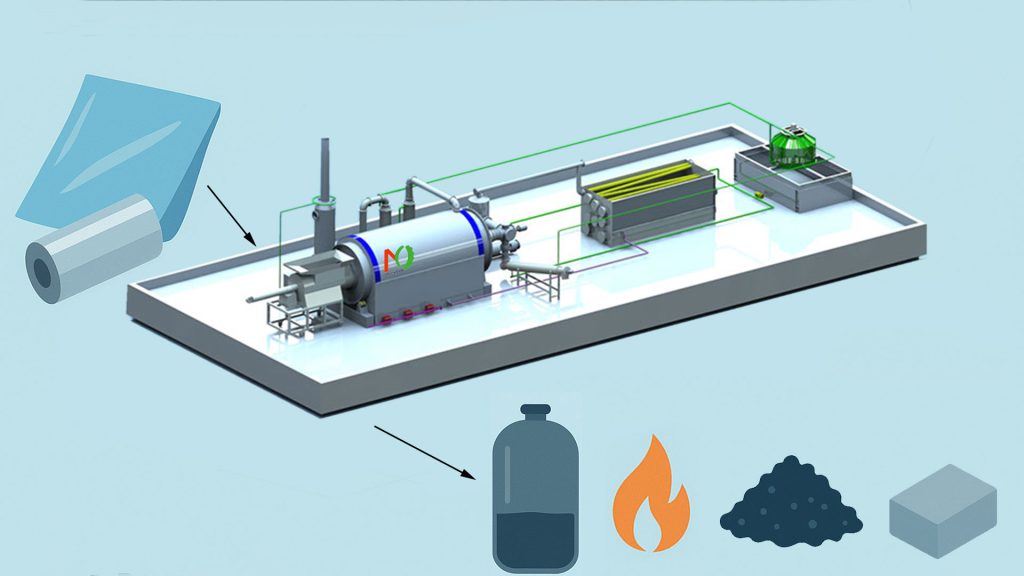

The aluminum plastic pyrolysis machine converts the plastic portion into combustible gas, pyrolysis oil, and carbon black. Simultaneously, it completely preserves the previously difficult-to-separate aluminum layer. Ultimately, it achieves complete separation of aluminum and plastic and resource recycling.

Aluminum Plastic Pyrolysis Application

The waste sources of aluminum plastic pyrolysis are wide-ranging, including Alu-PVC blister packs, aluminum-plastic films (lithium battery packaging), flexible packaging materials (food and daily chemical packaging), aluminum-plastic composite panels, and aluminum-plastic layers for wires and cables.

During the pyrolysis of aluminum plastic composites, the polymer chains of the plastic gradually break down under the influence of heat, generating small-molecule compounds. These small-molecule compounds exist in either gaseous or liquid states during the pyrolysis environment. Aluminum, due to its high melting point, does not undergo chemical decomposition during pyrolysis and remains solid. This difference allows for the effective separation of aluminum and plastic.

The small-molecule compounds generated during pyrolysis undergo further processing steps such as condensation and separation. They can be converted into economically valuable products, such as fuel oil and carbon black. This principle forms the basis of the entire aluminum-plastic pyrolysis process, determining the feasibility and advantages of pyrolysis technology in the field of aluminum plastic waste treatment.

The product composition of aluminum plastic pyrolysis is approximately 45% pyrolysis oil, 25% carbon black, 18% aluminum blocks, and 12% syngas.

Plastic Aluminum Pyrolysis Recycling Process

Aluminum plastic waste is fed into the plastic pyrolysis machine using a feeder. It is first heated to 120°C and maintained for 30 minutes to remove adsorbed moisture from the waste aluminum plastic raw materials. Then, the temperature is increased at a rate of 10°C/min, and pyrolysis gas begins to be generated at 150°C. The pyrolysis furnace is maintained under a slight negative pressure to begin low-temperature pyrolysis.

The oil-gas mixture produced by the aluminum plastic pyrolysis reaction enters the condenser. Most of the oil-gas is condensed, and the condensed pyrolysis oil is cooled, separated, and sent to the tank area for storage. Non-condensable syngas is recovered and used as fuel gas for the pyrolysis furnace heating reaction.

The collected non-condensable gas is mainly used for combustion in the pyrolysis reactor burner. Excess gas can be introduced into a dedicated combustion chamber for combustion. Combustion exhaust gas is introduced into an exhaust gas treatment system, treated by an alkaline spray tower + SCR denitrification + UV photolysis + activated carbon adsorption, before being discharged through a chimney.

After plastic pyrolysis to fuel oil, the heating device stops heating. The aluminum plastic pyrolysis equipment is equipped with a closed water-cooled spiral slag discharge system. The residue mainly consists of carbon black and aluminum blocks, which can be directly bagged and sold after screening.

Pyrolysis Equipment Manufacturer in China

Mingjie Group is a professional pyrolysis equipment manufacturer in China, providing integrated solutions for solid waste pyrolysis. Our pyrolysis equipments are highly adaptable, can handle plastics, tires, sludge, medical waste, municipal solid waste, industrial solid waste, and biomass waste. They fully meet the market demands for the resource recovery, reduction, and harmless treatment of organic waste.

Currently, Mingjie’s pyrolysis equipment has been applied in over 30 countries and regions worldwide. Numerous demonstration projects have fully validated the reliability and practicality of Mingjie’s pyrolysis equipment.