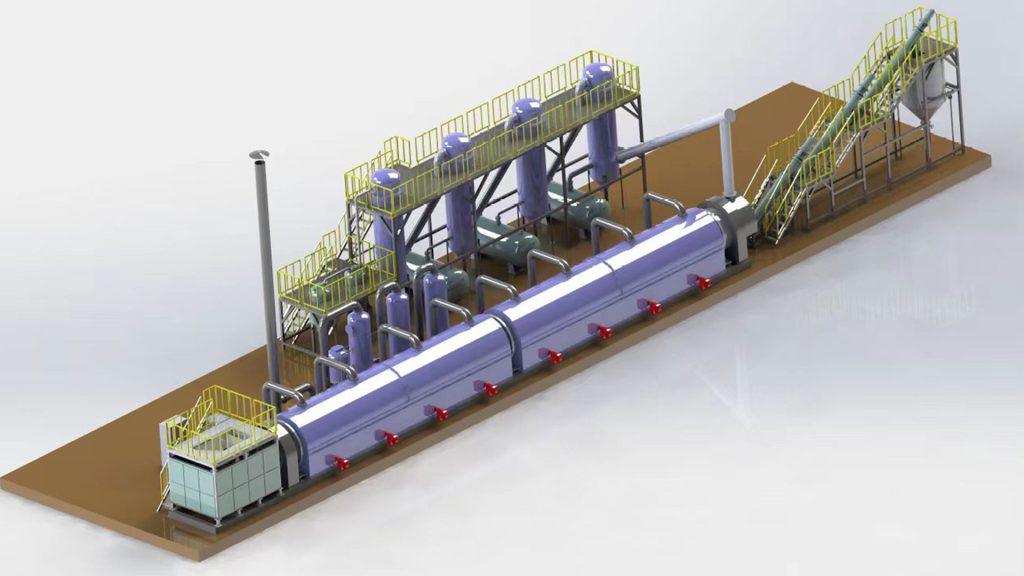

According to different working methods, tyre pyrolysis plant for sale can be divided into batch and continuous tire pyrolysis plant. Tire pyrolysis plant uses pyrolysis technology to convert waste tires into fuel oil, carbon black, syngas and steel wire. The principle of pyrolysis technology is to heat solid waste under oxygen-free or low-oxygen conditions. Its molecular structure is cracked to produce combustible gas, liquid oil and solid residue.

Application of Batch Tyre Pyrolysis Equipment

Small Enterprises: Batch tyre pyrolysis equipment has a daily processing capacity of about 1-15 tons. Batch pyrolysis equipment has relatively low investment and relatively simple operation, which can meet the needs of small-scale production.

Experiment or R&D: Mini batch pyrolysis equipment is suitable for some scientific research institutions or enterprises to conduct experimental research on new technologies and processes for tire pyrolysis. The small pyrolysis equipment adopts a skid-mounted design, which is convenient for transportation and operation. It can facilitate experiments under different conditions, flexibly adjust pyrolysis parameters, and facilitate observation and analysis of experimental results.

Unstable Raw Material Supply: When the supply source of waste tires is unstable, batch tire pyrolysis equipment can be processed in batches according to the arrival of raw materials. The entire production process will not be affected by the interruption of raw material supply.

Limited Funds: Due to the low initial investment cost of batch pyrolysis equipment, it is a more suitable choice for some investors with less funds. Investors can enter the waste tire pyrolysis treatment industry with less funds and gradually accumulate experience and funds.

Application of Continuous Tire Pyrolysis Plant

Large-scale enterprises: Suitable for enterprises with large waste tire processing capacity, with a daily processing capacity of 15-50 tons or even more. Fully automatic pyrolysis plant can meet the needs of large-scale industrial production. It can improve production efficiency, reduce unit costs, and achieve economies of scale.

High product quality requirements: Fully continuous pyrolysis plant can provide a more stable pyrolysis environment, making product quality more stable and uniform. For those enterprises with high quality requirements for pyrolysis products such as fuel oil and carbon black, fully continuous tire pyrolysis plants are a better choice.

Pursue high efficiency and environmental protection: The fully continuous tire pyrolysis equipment has a high degree of automation and is continuous and stable during operation. It reduces energy consumption and pollutant emissions caused by frequent start-up and shutdown of equipment. At the same time, its advanced environmental protection facilities such as exhaust gas treatment can better meet environmental protection requirements.

Long-term stable operation: The initial investment of a fully automatic tyre pyrolysis plant is large. But in the long run, its operating cost is relatively low and the equipment has a long service life. This can bring long-term and stable benefits to the enterprise and is suitable for enterprises with long-term development plans.

Differences Between Batch and Continuous Tire Pyrolysis Plant

The differences between batch and continuous pyrolysis plants lie in the operating mechanism, feeding and slagging method, degree of automation, processing capacity, equipment complexity, product quality, cost and energy efficiency. The choice of which method to use mainly depends on the investor’s budget.

Different Operating Mechanisms

Batch pyrolysis equipment processes tires in a cycle, “loading → pyrolysis → cooling → unloading”.

Fully continuous tire pyrolysis plant operates uninterruptedly, with continuous feeding, pyrolysis and slag discharge. It can achieve simultaneous feeding and slag discharge, so that the tires are continuously in a pyrolysis state.

Different Feeding Methods

Batch pyrolysis plant uses manual or simple hydraulic feeders. Feeding takes a long time, and it takes 2-3 hours to load a furnace. Batch tire pyrolysis equipment adopts a large furnace door design, which does not require high material dimensions. It can directly process whole tires and small-sized materials, such as rubber powder and rubber blocks. In the actual production process, batch pyrolysis equipment generally does not need to be equipped with a pretreatment device.

Fully continuous tire pyrolysis plant uses a fully automatic closed feeding system. Its feeding time is short, such as about 30 minutes. Continuous tire pyrolysis equipment uses a closed spiral feeding method and can only process small-sized materials such as rubber powder and rubber blocks. If the raw material is a whole tire, it is necessary to use a waste tire pretreatment device to break the whole tire into 5-8mm rubber blocks.

Different Slag Discharge Methods

Batch pyrolysis plant needs to cool down before slag discharge, and the cooling time for a single furnace is 4-5 hours. And most of them are open-type slag discharge, and the safety and environmental protection coefficient is low.

The slag discharge system of the fully continuous tire pyrolysis plant adopts a closed slag discharge design. The carbon black is directly packaged after water circulation cooling, which is safe and environmentally friendly.

Different Levels of Automation

Batch tire pyrolysis plant is semi-automatic and require 3-4 people to operate. It has high labor intensity and low automation. If secondary feeding, slag discharge or steel wire drawing is required, the pyrolysis reactor temperature needs to be cooled to below 60 degrees.

Fully continuous tire pyrolysis plant adopts PLC automated intelligent control systems and only require 1-2 people to operate. It has a high degree of automation and low labor intensity. Fully automatic pyrolysis plant can continuously feed and discharge slag and operate 24 hours a day.

Different Tire Processing Capacity

The daily processing capacity of a batch pyrolysis plant is 1 – 15 T/D. It has low operating efficiency and limited processing capacity, suitable for small-scale production.

The processing capacity of a fully continuous pyrolysis plant is 15 – 50 T/D. It has high operating efficiency and is suitable for large-scale industrial production.

Equipped with Different Systems

Batch pyrolysis equipment has a simple design and low requirements for automation and material pretreatment. It has flexible feeding methods, simple operation, few wearing parts, and low maintenance costs.

Fully automatic pyrolysis plant requires more complex equipment design and advanced automatic control capabilities. It has strict requirements for material pretreatment, complex equipment, and more wearing parts.

Different Final Product Quality

Batch pyrolysis equipment uses cyclic heating and cooling, which makes it difficult to ensure consistent product quality. Repeated thermal cycles reduce overall efficiency and poor product quality stability.

Fully continuous tire pyrolysis plant uses a continuous and stable environment to ensure stable final product quality.

Different Tire Recycling Pyrolysis Plant Cost

Batch type pyrolysis equipment is simple and is the most mature technology so far. It is also the most used by pyrolysis plant manufacturers and customers. A batch pyrolysis plant cost is between 300,000 and 500,000 US dollars.

Fully continuous tire pyrolysis plant has complex equipment, high degree of automation and strict raw material pretreatment. Its investment and operating costs are high, and the market quotation is mostly over one million US dollars.

Different Energy Utilization Efficiency

Each operation of the batch tyre pyrolysis equipment requires reheating and cooling. The energy utilization efficiency is relatively low and the energy consumption is high.

Fully continuous tire pyrolysis plants have higher heat transfer efficiency, which makes fuller use of heat and syngas. The continuous feeding and discharging system makes fuel consumption relatively low and saves 20% of operating costs.

Why Choose Us – Mingjie Group

Mingjie Group has 20 years of rich experience and focuses on the research and development of pyrolysis technology and equipment. Their excellent performance ensures stable operation of the equipment. We provide one-stop service, including raw material analysis, equipment customization, installation, training and maintenance. Our tyre pyrolysis plant price is affordable and sold directly from the Mingjie factory.

Batch pyrolysis plant and continuous tire pyrolysis plant have their own advantages and disadvantages. Find the best one that suits your company. When purchasing pyrolysis equipment, you must be clear about production capacity, material properties, input and output requirements, site conditions, investment budget and other information.