As one of the few solutions that can actively remove carbon from the atmosphere, biochar technology is playing an increasingly important role in global carbon neutrality strategies. Choosing the right biochar machine manufacturer is not only an economic decision, but also an investment in a sustainable future.

With the improvement of carbon pricing mechanisms and the development of carbon markets, the economics and attractiveness of biomass carbonization project will further increase. The biomass pyrolysis technology and charcoal production equipment provided by Biochar Machine Manufacturers will be a key driver of this transition.

How to Choose a Biochar Machine Manufacturer

Choosing a biochar machine manufacturer is a comprehensive decision-making process that requires balancing multiple factors, including technical performance, cost, after-sales service, and long-term reliability. Based on industry practices, the following are key factors to consider when selecting a manufacturer:

Technology and Equipment Performance

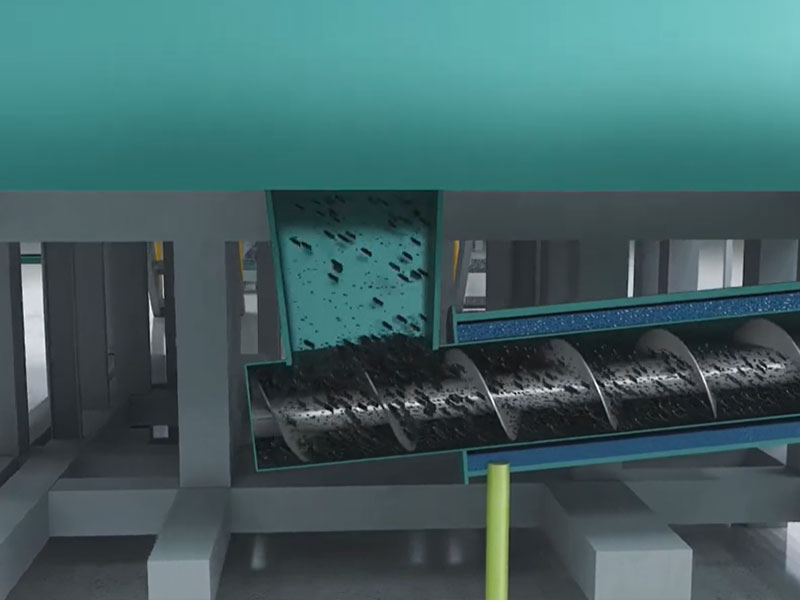

Pyrolysis Technology Type: Evaluate whether the biochar machine manufacturer uses a continuous or batch pyrolysis system. Continuous systems are generally more efficient and energy-efficient, making them suitable for large-scale biochar production. Batch systems, on the other hand, may require a lower investment and are suitable for small-scale biochar production.

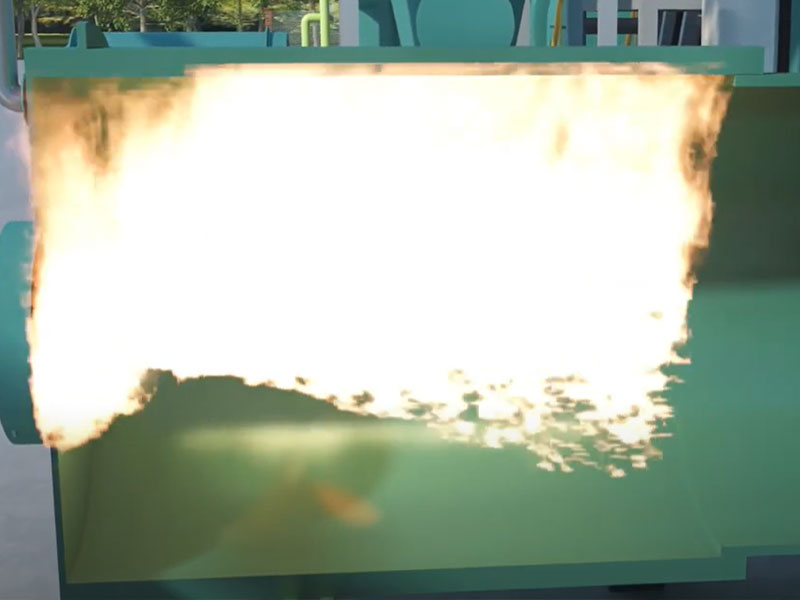

Energy Efficiency: Examine the equipment’s energy consumption. High-quality biochar equipment should be energy self-sufficient. It means that it operates using own syngas, requiring little or no external energy input.

Feedstock Flexibility: High-quality equipment should be able to process a variety of biomass feedstocks. Some advanced biomass carbonization equipment can even process municipal and industrial sludge.

Level of Automation: Modern biomass carbonization plant should utilize a PLC control system, enabling real-time monitoring and automated control of key parameters (temperature, pressure, and feed rate).

Equipment Certification

The compliance of biochar equipment directly impacts the market acceptance of the product:

Safety Certification: Check whether the biochar equipment meets international standards such as CE and ISO certification.

Emission Compliance: The biomass pyrolysis equipment must meet emission standards, ensuring that limits are met for greenhouse gases (methane, nitrogen oxides, CO2) and air pollutants (flue gas, dust, ash).

Production Capacity and After-Sales Service

Manufacturer Strength: Evaluate the biochar machine manufacturer factory scale, employee technical qualifications, and quality control system.

After-Sales Service: Verify whether the manufacturer offers 24/7 online support and one-stop design services. Design, manufacturing, installation, and commissioning services are hallmarks of a high-quality biochar machine manufacturer.

Reference Cases: Provide customer references for similar feedstock applications. Ideally, conduct an on-site visit to verify the authenticity of the manufacturing process.

Return on Investment Analysis

The profitability of a biomass pyrolysis project depends on the efficiency of the biochar equipment, operating costs, and product value.

Biomass Pyrolysis Plant Manufacturer in China

Mingjie Group is a professional Chinese biomass pyrolysis plant manufacturer with cost advantages and innovative breakthroughs. Mingjie Pyrolysis Plant Manufacturer has a research and development team composed of senior engineers and environmental experts, constantly promoting technological innovation.

Our factory has a CNC equipment workshop with an area of 12,000 square meters, and the master has more than 20 years of experience in equipment manufacturing.

We offer continuous carbonization systems from small to large scale. Input capacities range from 100kg/h to 5000kg/h, and we accept a wide range of feedstocks, including bamboo, wood charcoal, rice husk, straw, coconut shell, palm shell, sawdust, bagasse charcoal, and sewage sludge.

Our Pyrolysis Plants are CE and ISO certified. We have provided customized environmental solutions to more than 200 customers around the world. And have successfully implemented a number of large-scale tire, plastic recycling, and biomass carbonization projects in more than 30 countries, winning wide recognition.

We also provide one-stop service, including Solution Design, Sample Testing, Equipment Installation and Commissioning, 24h Online Service, and EIA Guidance.