Mingjie biochar manufacturing equipment utilizes a continuous pyrolysis system. The slow pyrolysis process is designed to maximize fixed carbon yield. The biomass carbonization plant integrates multiple stages, including drying, pyrolysis, gas combustion, and product cooling. It achieves continuous biomass feeding and stable biochar production.

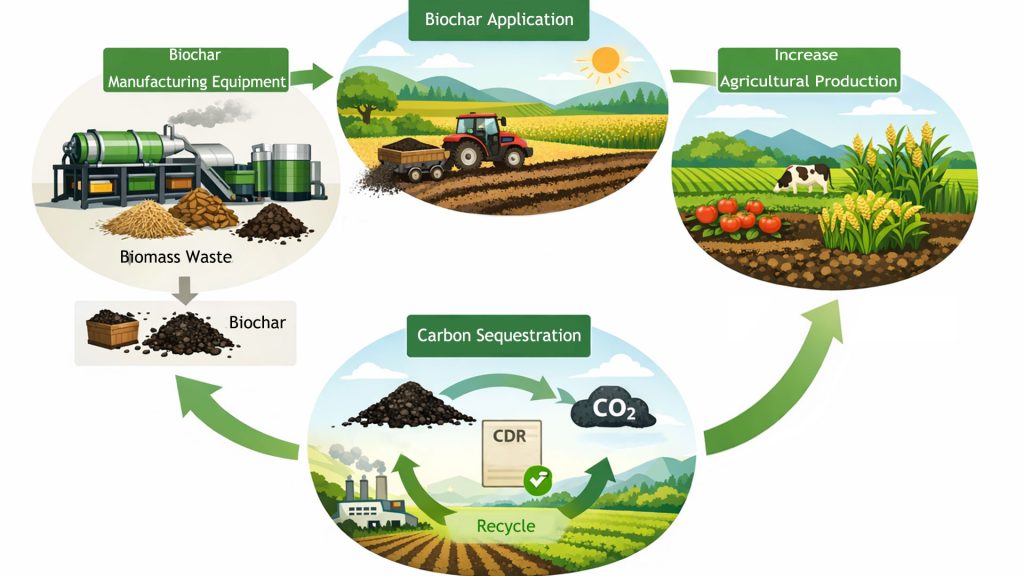

Unlike biomass energy, biochar is produced through biomass pyrolysis plant, and the resulting biochar is applied to the soil. Because biochar loses almost all its chemical and biological activity after pyrolysis, it is extremely difficult for it to react with other substances. This prevents the carbon elements in the biochar from returning to the atmosphere for over 100 years.

Biochar essentially fixes carbon dioxide from the air into the soil, indirectly removing carbon dioxide from the atmosphere. Therefore, biomass to biochar projects are classified as carbon removal projects.

Carbon removal projects typically have high costs, and therefore their corresponding carbon credits are also relatively expensive. Currently, the average transaction price for biochar-based carbon credits is as high as $160 per ton. This is significantly higher than the price of carbon assets from carbon reduction and forestry carbon sink projects. Other carbon removal projects, such as Direct Air Carbon Capture and Storage (DACCS), can cost up to $1000 per ton!

Carbon Sequestration Potential of Biochar

The high chemical stability and carbon sequestration potential of biochar were confirmed through analysis of the biochar product, demonstrating its excellent stability. The H/Corg ratio was 0.41 and the O/Corg ratio was 0.31, both below the thresholds specified by the European Biochar Certificate (EBC) (0.7 and 0.4). This indicates a highly aromatic structure and chemical inertness, making it resistant to microbial decomposition. A thermal stability index of 83% further confirms its resistance to thermal and biological degradation.

Based on these stability parameters, the study estimated the carbon sequestration potential of this biochar to be 1.67 tons of CO2 equivalent per ton of biochar. It is predicted that its stability in soil can exceed 100 years, demonstrating its direct value in addressing climate change.

In addition to enabling carbon sequestration, biochar manufacturing equipment offers multiple benefits. These include improving soil porosity, reducing soil compaction, slowing nutrient release, increasing the efficiency of nitrogen, phosphorus, and potassium, and improving the soil microbial environment.

Biochar Manufacturing Equipment Application

Biochar manufacturing equipment demonstrates exceptional performance in various aspects. Including waste resource utilization, soil improvement, crop growth promotion, and carbon emission reduction. It has become a crucial force in achieving sustainable development in the agricultural sector.

The application scope of biochar manufacturing equipment will continue to expand. Besides its traditional applications in agriculture, it will also play a significant role in horticulture, forestry, and ecological restoration.

- In horticulture, biochar can be used as a growing medium, improving soil structure and enhancing the growth quality of flowers, vegetables, and other crops.

- In forestry, biochar contributes to the improvement of forest soil and tree growth, strengthening the stability of forest ecosystems.

- In ecological restoration, biochar can be used to repair damaged soil and aquatic ecosystems, promoting the recovery and improvement of the ecological environment.

Technological Optimization of Biochar Production Equipment

Mingjie biochar production equipment will develop towards a more efficient, intelligent, and environmentally friendly direction.

On the one hand, technical personnel will focus on optimizing production processes to improve the efficiency and quality of biochar production and reduce production costs. By improving pyrolysis technology, biomass can be converted into biochar in a shorter time, while improving the stability and activity of the biochar.

On the other hand, intelligent technology will be widely applied in biochar manufacturing equipment to achieve automated control and remote monitoring. This will improve the precision and reliability of the production process, reduce manual intervention, and lower labor intensity.

In terms of environmental protection, biochar manufacturing equipment will focus more on energy saving and emission reduction, reducing pollutant emissions during the production process. More environmentally friendly materials and processes will be adopted to achieve green production.