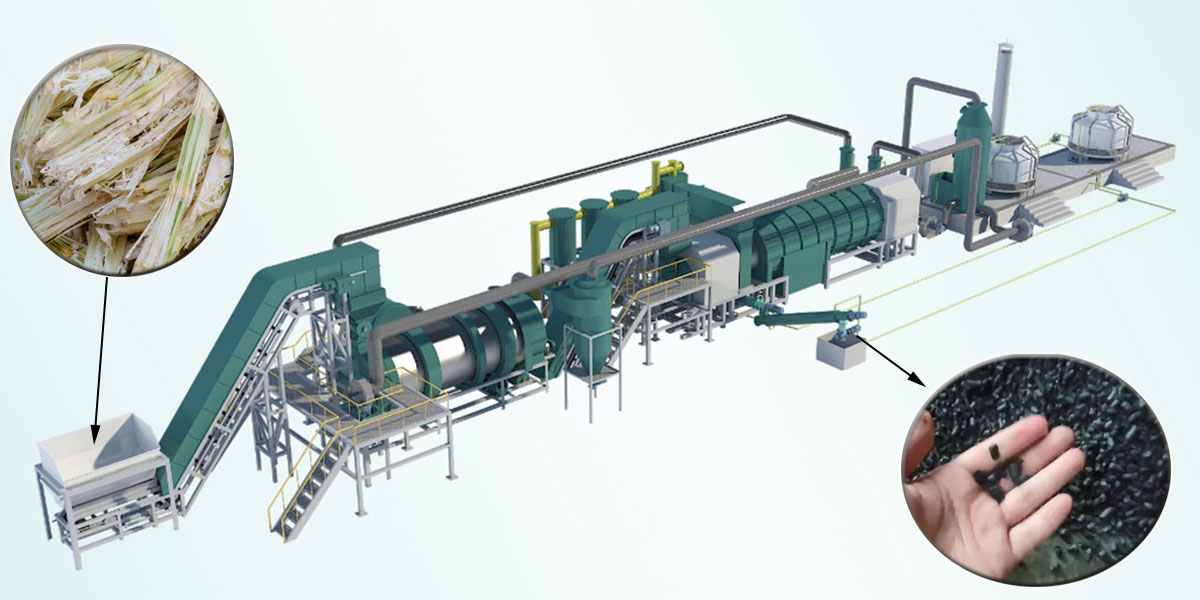

Biochar production machine can convert bagasse into charcoal, opening up a new path for the resource utilization of bagasse. It realizes the gorgeous transformation of bagasse from waste to high-value biochar products.

Bagasse is a kind of biomass. Bagasse is the solid waste left after sugarcane is squeezed to extract juice. Its main components are cellulose (about 40%~50%), hemicellulose (about 20%~30%) and lignin (about 15%~25%), all of which are typical organic compounds. From the source point of view, sugarcane is a crop, and its processed waste bagasse belongs to plant biomass.

Recycling of Waste Biomass Bagasse

For a long time, the fate of most bagasse has not been optimistic.

About 80% of bagasse is used as boiler fuel. Waste biomass bagasse is burned directly in the boiler of the sugar factory to provide heat for sugar production.

This utilization method is simple and direct, but the disadvantages are obvious. The steam and electricity generated by the combustion of bagasse can only meet the needs of the sugar factory itself, and the energy utilization efficiency is low. In addition, a large amount of smoke and carbon dioxide will be generated during the combustion process, which will put great pressure on the environment.

Some bagasse has been tried as feed. However, due to its high cellulose and lignin content, its nutritional value is relatively low. Bagasse is difficult to become the main source of animal feed, and its application range is very limited.

A small part of bagasse is also used to make paper. However, there are many impurities in bagasse, and the preparation of paper requires complex pretreatment and purification processes. This leads to high costs for making paper from bagasse and difficulty in improving production efficiency.

With the increasing awareness of environmental protection and the popularization of the concept of sustainable development, it is urgent to find a more efficient and environmentally friendly method for the treatment of sugarcane bagasse. Until the emergence of biomass pyrolysis plant, it can convert these waste biomass into high-value biochar products.

Principle of Bagasse Pyrolysis Carbonization

The bagasse pyrolysis carbonization is a magical transformation in the microscopic world. In a low-oxygen and high-temperature environment, the organic matter (cellulose, hemicellulose and lignin) in the bagasse begins to undergo a series of complex changes in the biochar production equipment.

Before pyrolysis of bagasse, it needs to be dried to keep the moisture content below 15%, which is conducive to the subsequent biomass pyrolysis. The biomass to biochar production machine uses external heating to continuously increase the temperature in the reactor.

Bagasse Pyrolysis Process

When the temperature reaches 150-250℃, hemicellulose undergoes pyrolysis reaction first. The structure of hemicellulose is relatively loose, and its molecular chain begins to break in this temperature range. It decomposes to produce some low-molecular-weight volatile compounds, such as furfural, acetic acid, methanol, etc. These small molecules escape in the form of gas.

When the temperature further rises to 250-400℃, cellulose (a relatively regular macromolecular structure) undergoes depolymerization and decomposition reactions. The glycosidic bonds in the cellulose molecules break to generate a series of pyrolysis products. These include left-handed glucose, oligosaccharides, and some gaseous products, such as carbon monoxide, carbon dioxide, and hydrogen. Left-handed glucose is an important intermediate product in the pyrolysis of cellulose. It can also be further decomposed or undergo secondary reactions to be converted into other more complex compounds.

The pyrolysis process of lignin is more complicated. Due to its highly cross-linked three-dimensional network structure, the pyrolysis reaction is relatively slow and has a wider continuous temperature range. It is roughly carried out in the temperature range of 250-500℃ or even higher. When lignin is pyrolyzed, various chemical bonds in its molecules, such as ether bonds, carbon-carbon bonds, etc., gradually break. Finally, a variety of aromatic compounds, phenolic substances and some gas products are generated.

Bagasse Pyrolysis Products

As the temperature rises and the pyrolysis reaction proceeds, the biochar production machine converts waste biomass bagasse into charcoal, syngas and tar products.

Charcoal is the main solid product of biomass pyrolysis carbonization. It retains most of the carbon elements in the bagasse, has a high fixed carbon content and rich pore structure. These pore structures give charcoal many special properties, such as a large specific surface area, which enables it to play an important role in adsorption, catalysis and other fields.

The syngas products mainly include carbon monoxide, carbon dioxide, hydrogen, methane, etc. These synthetic gases have a certain calorific value and can be used as fuel to provide energy for industrial production or daily life.

Tar is a black, viscous liquid. Tar is a complex mixture containing a variety of organic compounds, such as phenols, aromatics, heterocyclic compounds, etc. After further separation and purification, many valuable chemical raw materials can be extracted from it.

How Biochar Production Machine Works

For the continuous pyrolysis and carbonization of the biochar production machine, the bagasse needs to be crushed and dried before entering the pyrolysis reactor. Mingjie Biochar Pyrolysis Plant is equipped with crushers and dryers. They can process the bagasse material size to less than 20mm and the moisture content is less than 15%.

The continuous biomass carbonization machine adopts a rotary double-cylinder structure. The inner cylinder is mainly responsible for pre-drying. When the preliminarily dried bagasse enters the inner cylinder, the residual moisture will be further removed here to prepare for the subsequent carbonization reaction. The outer cylinder is the main place for the carbonization reaction. When the bagasse enters the outer cylinder from the inner cylinder, the material stays in the reactor for 15-25 minutes to complete the carbonization process.

During the entire pyrolysis process, the organic matter in the bagasse is continuously decomposed and transformed, and finally three main products are formed: biochar, gas and tar.

Carbonized biochar needs to be cooled to stabilize its state. The biomass carbonization plant uses a water-cooled carbon discharging screw to remove the carbon. It uses the good heat dissipation performance of water to quickly cool the biochar.

The cooled biochar can be further processed as needed. The Charcoal Briquette Making Machine can process biochar into various shapes, such as common blocks, columns, etc.

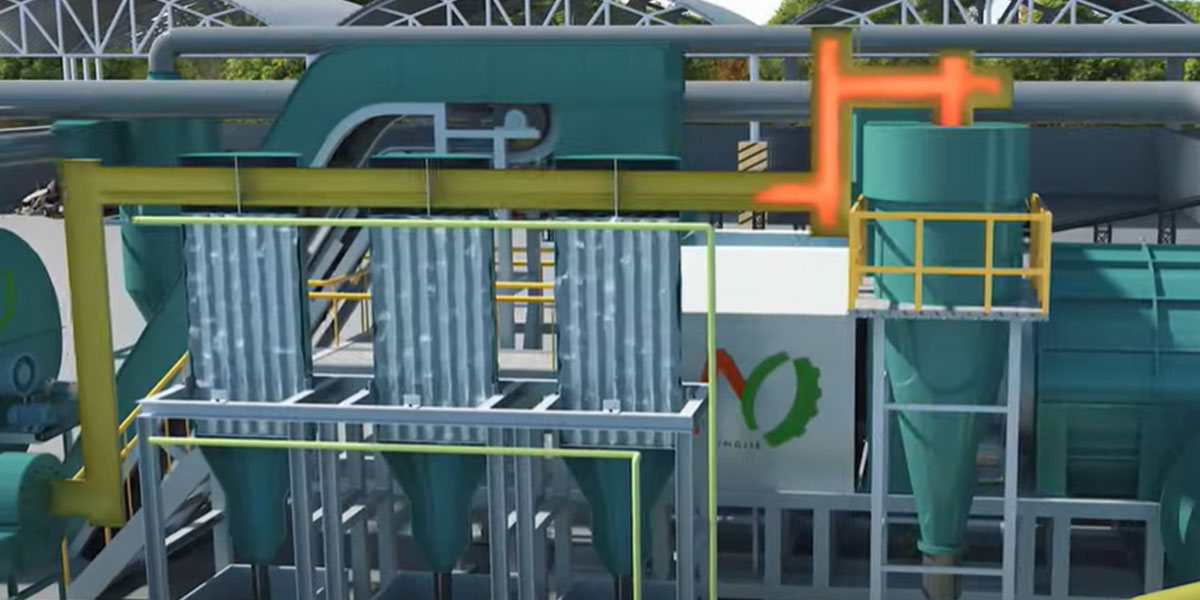

In the process of sugarcane bagasse pyrolysis and carbonization, in addition to the main product of biochar, by-products such as gas and tar are also produced. Tar and synthesis gas are separated by condensation and purification. The purified synthesis gas can be recycled as a heating source for the pyrolysis reactor, or transported to gas boilers, internal combustion engines and other equipment. The high-temperature flue gas generated during the pyrolysis process is further purified to enable it to meet emission standards.

Summary

The biochar production machine has a wide range of application prospects. It can process agricultural and forestry waste and animal manure. Bagasse biochar production machine can make waste resources sustainable and reduce carbon emissions to achieve environmental protection.