In the biochar production process, carbonization equipment plays a key role. Appropriate equipment can ensure the efficient carbonization reaction of waste biomass. It improves the yield and quality of biochar while reducing production costs. Choosing the right carbonization equipment is crucial to achieving the economic and environmental benefits of biochar production.

Biomass pyrolysis machine is the core device for pyrolysis of biomass into biochar. It plays a key role in the process of efficiently converting biomass resources into high value-added products. At the same time, continuous pyrolysis technology can bring many benefits to enterprises, such as reducing carbon emissions, using renewable resources and reducing energy costs.

Biomass pyrolysis technology is a green and environmentally friendly way of energy conversion. It converts waste biomass into biochar, bio-oil and syngas. Biomass pyrolysis machine promotes the decomposition reaction of biomass at high temperature by creating an oxygen-free or low-oxygen environment.

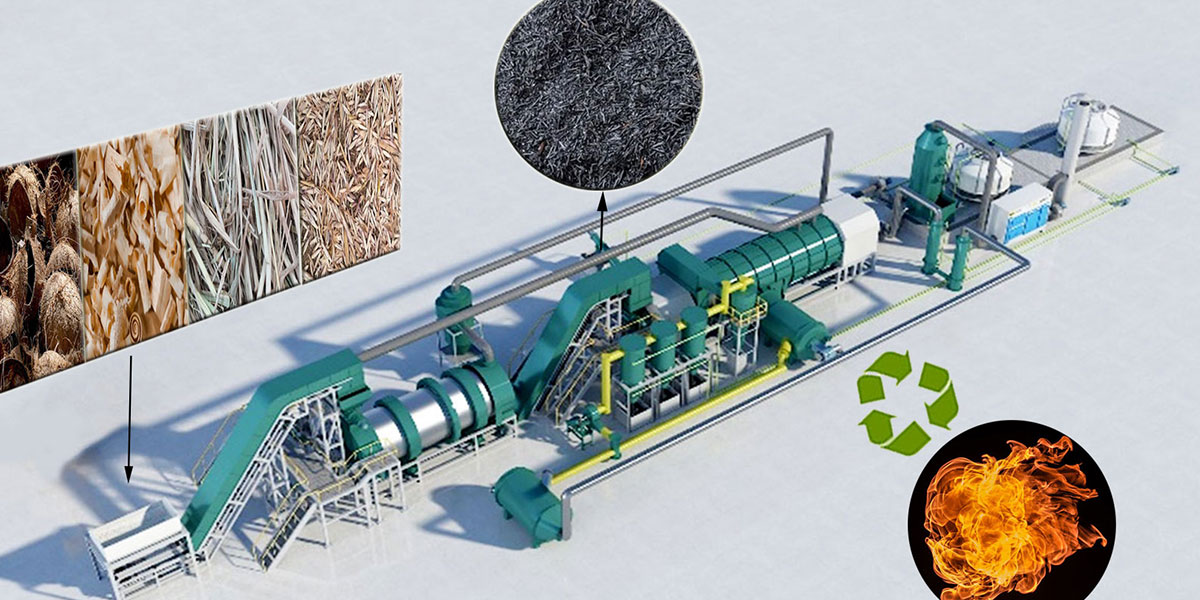

Biomass Pyrolysis Plant for Biochar Production

Biomass pyrolysis plants can process a variety of waste biomass, including wood, straw, rice husks, coconut shells, animal manure and other organic materials. The reuse of these waste biomass not only reduces costs, but also solves the problem of waste disposal.

The pyrolysis carbonization process can not only convert waste biomass into high-value energy and products. It can also achieve the recycling of resources and reduce the pressure on the environment. During the carbonization process of the continuous biomass carbonization plant, the combustible gas produced is used as fuel for the carbonization furnace. In addition, the flue gas from the carbonization process can also provide energy for the drying equipment.

Equipment Required for Biomass Pyrolysis to Biochar

Raw Material Pretreatment Equipment

Before entering the biochar production machine, the biomass must meet certain feed requirements. Its moisture content should be less than 15% and the particle size should be less than 20 mm. Biomass raw materials usually come from a wide range of sources and have different shapes and sizes. It is difficult to ensure efficient and stable reaction when directly pyrolyzing large-sized biomass. We can provide pretreatment equipment: crusher and dryer.

Auxiliary Equipment

Conveying Equipment

Conveying equipment plays a vital connecting role in the production process of biomass pyrolysis biochar. It is responsible for conveying raw materials from the storage area to the pretreatment equipment, conveying the pretreated raw materials to the pyrolysis core equipment, and conveying the pyrolysis products to the subsequent processing equipment.

Common conveying equipment includes belt conveyors, screw conveyors and bucket elevators.

In large-scale biomass pyrolysis biochar production plants, belt conveyors can continuously convey a large amount of biomass raw materials such as straw and sawdust collected from the yard to the crusher for pretreatment to ensure the continuity of production.

The screw conveyor pushes the material forward through the rotation of the spiral blade. It has a compact structure and good sealing performance, and is suitable for conveying some materials that need to be conveyed in a sealed environment.

Bucket elevators are mainly used to lift materials vertically and can lift materials to a certain height. In the production of biomass pyrolysis biochar, it is often used to lift pretreated raw materials to the feed port of the pyrolysis furnace, or to lift cooled biochar to the packaging equipment.

Control System

The PLC control system is the “brain” of the entire biochar production process. It can monitor and precisely control the operating parameters of each system in real time. This ensures the stable and efficient operation of the entire biochar production process. The control system not only improves the efficiency of automated production, but also improves the stability of product quality.

The control system obtains the key parameters of the pyrolysis furnace (temperature, pressure, gas flow) through sensors and transmits these data to the controller. The controller analyzes and processes the data according to the preset program and parameter range. Then it issues instructions to adjust the power of the heating system, the feed rate of the pyrolysis furnace, the operating status of the gas treatment equipment, etc.

In addition, the control system also has fault diagnosis and alarm functions. When the equipment fails or the operating parameters are abnormal, it can issue an alarm in time and take corresponding protective measures to avoid accidents.

Carbonization Equipment

Carbonization equipment is the key to converting biomass pyrolysis into biochar. Its performance directly affects the yield, quality, energy efficiency and cost of biochar. Carbonization equipment mainly includes carbonization furnace and heating system.

Carbonization Furnace

The carbonization furnace is the core reaction device of the biochar production process. Its working principle is to provide an oxygen-free or low-oxygen high-temperature environment for biomass to cause pyrolysis reaction. In the carbonization furnace, as the temperature rises, the chemical bonds in the biomass gradually break, and complex organic macromolecules are decomposed into simple small molecules, such as biochar, bio-oil and syngas.

The main structure of the rotary pyrolysis reactor is a rotatable cylindrical furnace body. It is usually installed slightly tilted. The biomass raw material enters from one end of the furnace body, and during the rotation of the furnace body, the material moves along the axial direction of the furnace body. At the same time, it exchanges heat with the furnace wall to achieve pyrolysis reaction.

This rotary carbonization furnace has strong adaptability to materials and can handle biomass raw materials of different shapes and properties. And the carbonization equipment operates stably, the operation is relatively simple, and it is suitable for large-scale production. When processing wood waste, the rotary pyrolysis furnace can operate continuously to achieve efficient pyrolysis conversion.

Heating System

The function of the heating system is to provide the required heat for the pyrolysis process and ensure that the pyrolysis reaction is carried out within a suitable temperature range. Biomass pyrolysis is generally heated by gas. It heats the carbonization furnace by burning natural gas to release heat energy. This heating method has high thermal efficiency and relatively low fuel cost, and is suitable for large-scale biochar production.

Biochar Collection Equipment

Biochar is continuously discharged from the outer cylinder of the pyrolysis reactor. It is sent to the storage tank or packaging bag through the water-cooled carbon outlet spiral device.

Water cooling uses water as a cooling medium, and the high-temperature biochar exchanges heat with water through a heat exchanger. After the water absorbs heat, the temperature rises, and the biochar is cooled. Water cooling has the advantages of fast cooling speed and good cooling effect. It can quickly reduce the temperature of biochar to a safe storage range.

Flue Gas Treatment System

Cyclone Dust Removal System

During the biochar production process, gas products containing solid particles are produced. As an efficient and economical gas-solid separation equipment, the cyclone dust removal system can effectively remove solid particles in the gas.

The cyclone dust removal system realizes gas-solid separation based on the principle of centrifugal force. The dust-containing gas enters the cylinder of the cyclone dust collector at a high speed along the tangential direction from the air inlet pipe. It begins to rotate in a spiral shape, forming an outer vortex.

Under the action of centrifugal force, the solid particles with larger mass are thrown to the inner wall of the cylinder. And under the combined action of gravity and airflow, they slide down along the inner wall of the cylinder and are finally discharged from the ash discharge port. The purified gas forms an upward inner vortex near the central axis and is discharged from the exhaust pipe at the top.

Condenser

The condenser is an important heat exchange equipment, which is used to cool the mixed gas produced by pyrolysis. The gaseous bio-oil and water vapor therein are condensed into liquid, thereby achieving separation from the pyrolysis gas. The condenser can not only recover tar products, but also reduce the load of subsequent gas processing. It improves the purity of combustible gas and creates conditions for its further utilization.

The working principle of the condenser is based on heat exchange. When the high-temperature mixed gas enters the condenser, it exchanges heat with the cooling medium (usually water or air). The heat in the mixed gas is transferred to the cooling medium, and its own temperature is reduced. As the temperature decreases, the gaseous bio-oil and water vapor reach saturation, undergo phase change, and change from gas to liquid. Collected by the condensate collection device.

The water-cooled condenser uses water as the cooling medium, has a high heat transfer efficiency, can quickly cool down the mixed gas, and is suitable for large-scale biochar production. The air-cooled condenser uses air for cooling, has a relatively simple structure, does not require a complex water circulation system, and is suitable for some small or water-restricted production occasions.

Spray Tower

The main function of the spray tower is to remove impurities and harmful gases remaining in the flue gas. After the flue gas mixed with water vapor passes through the cyclone dust collector, it enters the spray tower for water washing, porcelain ring adsorption and water spraying. Finally, it is discharged after being filtered by photo-oxidation and activated carbon adsorption.

When the flue gas enters from the bottom of the scrubber, it flows upward and contacts the absorption liquid sprayed from the top of the tower in countercurrent. The absorption liquid is usually selected according to the properties of the impurities and harmful gases to be removed. For example, water can absorb gases that are easily soluble in water, such as ammonia. During the contact process, impurities and harmful gases in the synthesis gas are captured by the absorption liquid and dissolved in the absorption liquid, thereby achieving purification.