The biomass to biochar production line is a set of equipment used to convert biomass materials (wood, straw) into biochar. It is suitable for large-scale biochar production projects. The expansion of biochar production scale can bring a series of synergistic effects and economies of scale to enterprises. Production scale is an important factor affecting the biochar production cost.

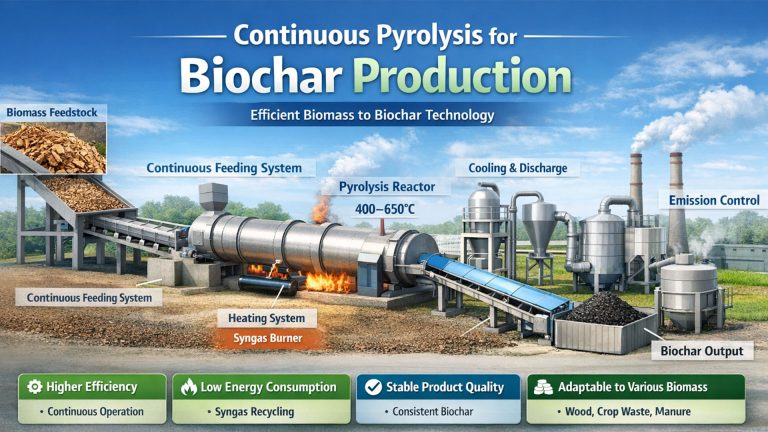

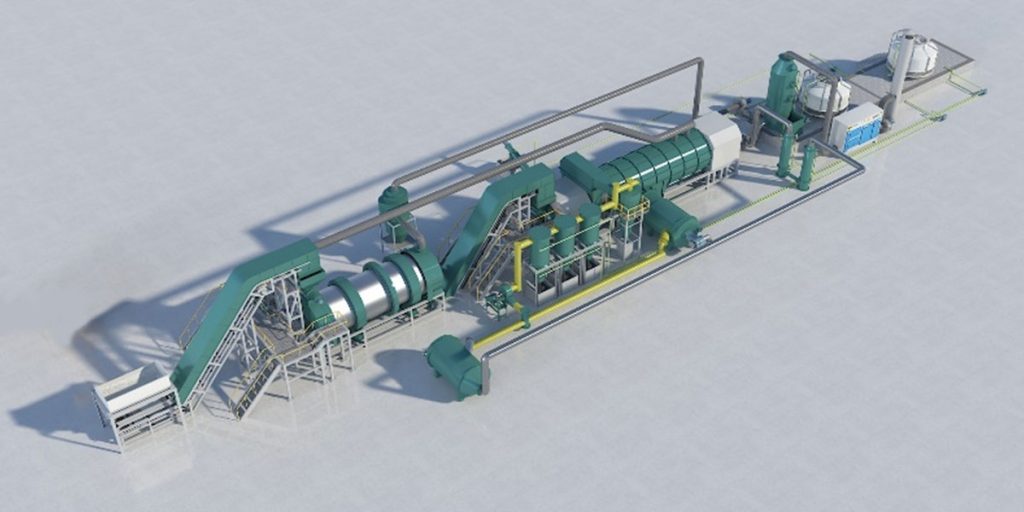

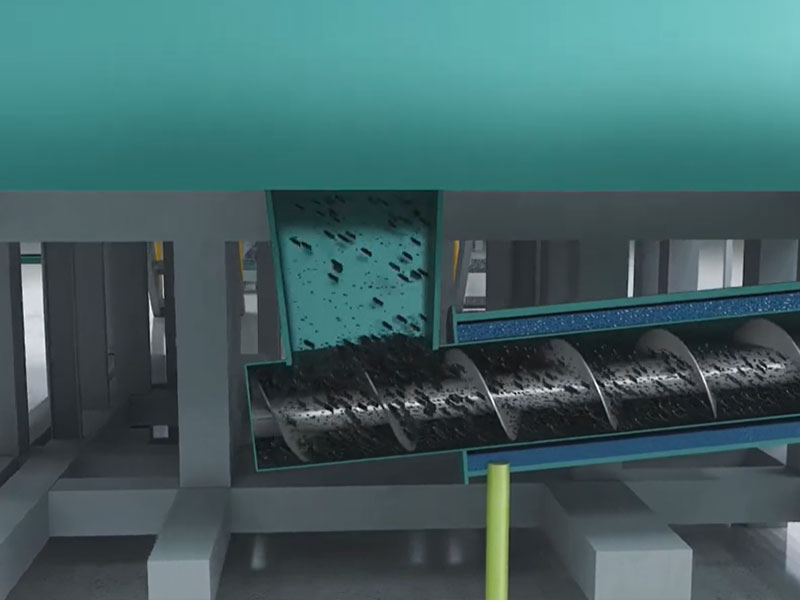

The biomass to biochar production line is a complex and sophisticated system that integrates a variety of advanced technologies. It can ensure that biomass can be efficiently and stably converted into high-quality biochar. Its main process flow includes biomass raw material preparation, pyrolysis carbonization process, biochar colloction, pyrolysis oil and gas separation, combustible gas recovery, and flue gas purification.

Large Scale Biochar Production Equipment Cost

As for large-scale continuous biochar production line, the biomass carbonization plant price may be as high as millions of US dollars. These large-scale biochar production equipment usually have a higher degree of automation and can achieve large-scale industrial production. It can process several tons or even tens of tons of biomass raw materials per day.

The processing capacity of the biomass pyrolysis plant is undoubtedly one of the key factors affecting the price. The larger the processing capacity of the biochar production equipment, the more complex its internal structure and production process are. It needs to be equipped with high-power motors, durable materials and more sophisticated control systems to ensure the stability of the biochar pyrolysis machine. This increases the cost of the biochar production line, which in turn leads to price increases.

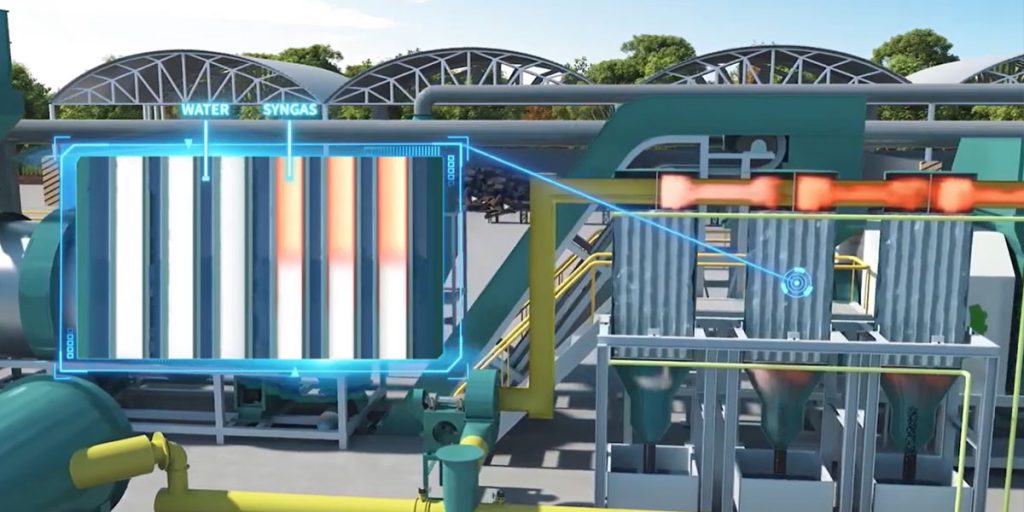

The technical level of the biomass carbonization machine is also an important factor in determining the price. Such as efficient continuous pyrolysis process, precise temperature control system, waste heat recovery technology, flue gas purification system and automatic control system. These systems can improve pyrolysis efficiency, reduce energy consumption, reduce manual intervention, and thus improve product quality and production efficiency.

The combustible gas generated during the carbonization process can be reintroduced into the carbonization furnace as fuel after purification. Syngas provides part of the heat for the carbonization process, thereby reducing the consumption of external energy.

The hot flue gas recycling system recycles the high-temperature flue gas discharged from the carbonization furnace. The heat is used to dry the biomass raw materials through the heat exchanger to achieve the recovery of waste heat.

Benefits of Biochar Production Line

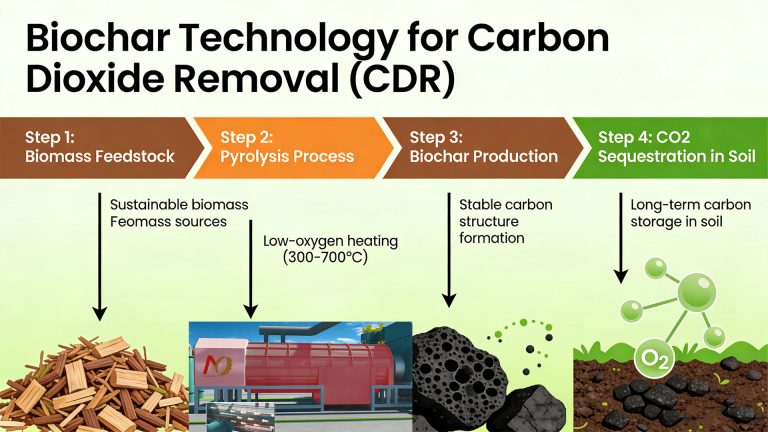

Outstanding environmental benefits: biomass to biochar production line realizes the resource utilization of waste through continuous pyrolysis technology. It reduces the pollution caused to the environment by direct incineration or natural degradation of biomass waste.

At the same time, the application of biochar in soil can fix carbon elements, reduce the emission of greenhouse gases such as carbon dioxide, and help alleviate global climate change.

In addition, the biochar production line is equipped with an advanced purification system that can effectively remove harmful substances (dust, sulfur dioxide, nitrogen oxides) from combustion exhaust gas. It can ensure that emissions meet standards and protect the atmospheric environment.

Considerable economic benefits: On the one hand, biochar has a wide application market and high economic value. It can be sold as a soil conditioner, adsorbent, energy fuel, bringing considerable sales revenue to the company. On the other hand, during the operation of the biochar production line, the recycling of combustible gas and hot flue gas reduces energy consumption and production costs.

In addition, the source of biomass raw materials is wide and the price is relatively low, which further reduces the production cost. At the same time, with the expansion of the scale of biomass pyrolysis, the production cost of biochar is expected to be further reduced.

Circular economic development: The biomass to biochar production line builds a complete circular economic industry chain. From the collection of biomass raw materials, to the production of biochar, to the recycling of combustible gas generated during the production process. Each link is closely linked to achieve efficient recycling of resources. This circular economic model not only conforms to the concept of sustainable development, but also provides new opportunities for the development of related industries.