Faced with the dire situation of plastic pollution, pyrolysis technology is gradually gaining attention as a highly promising solution. Pyrolysis solution for plastic pollution is a thermochemical process that decomposes organic matter at high temperatures oxygen-free environment. Pyrolysis equipment can break down complex, large-molecule plastics into smaller molecules. The final products are pyrolysis oil, carbon black, and synthesis gas.

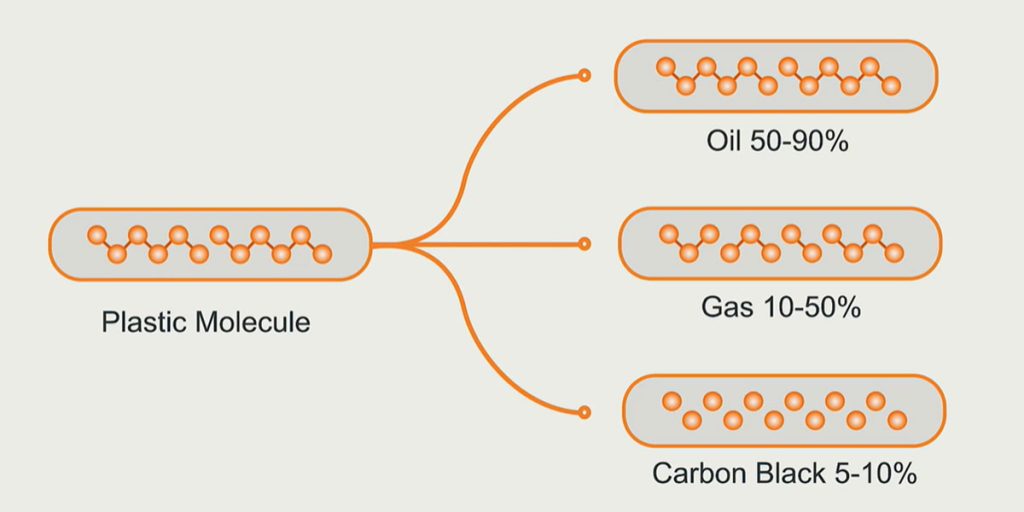

Plastics are primarily composed of high-molecular-weight polymers composed of elements such as carbon and hydrogen. Common polyethylene (PE) plastic, for example, is composed of a long chain structure consisting of numerous repeating ethylene monomers (-CH₂-CH₂-).

When polyethylene plastic enters a pyrolysis reactor, the covalent bonds between its molecules begin to break under high temperatures of 400-600°C. These small molecular fragments recombine to form various low-molecular-weight compounds, such as gaseous hydrocarbons like methane (CH₄), ethane (C₂H₆), and propane (C₃H₈), as well as liquid hydrocarbons such as C₁₂-C₂₂. These are the main components of crude oil.

In addition, the plastic pyrolysis process produces a small amount of solid residue, primarily carbon black. This carbon black can be further processed and used as a reinforcing agent for rubber products and a pigment for inks.

Pyrolysis Project Solution for Plastic Pollution

Pyrolysis solutions for plastic pollution have already found application in the industrial sector. Several large plastic recycling plants have purchased pyrolysis equipment and are operating efficiently. Waste plastics are continuously fed into pyrolysis reactors. After a series of processes, including high-temperature decomposition and condensation separation, they are ultimately converted into valuable fuel oil and reusable chemical raw materials.

Mingjie pyrolysis plant has been used in plastic pyrolysis projects in many countries, including Thailand, Pakistan, the Philippines, Poland, the Czech Republic, Romania, etc.

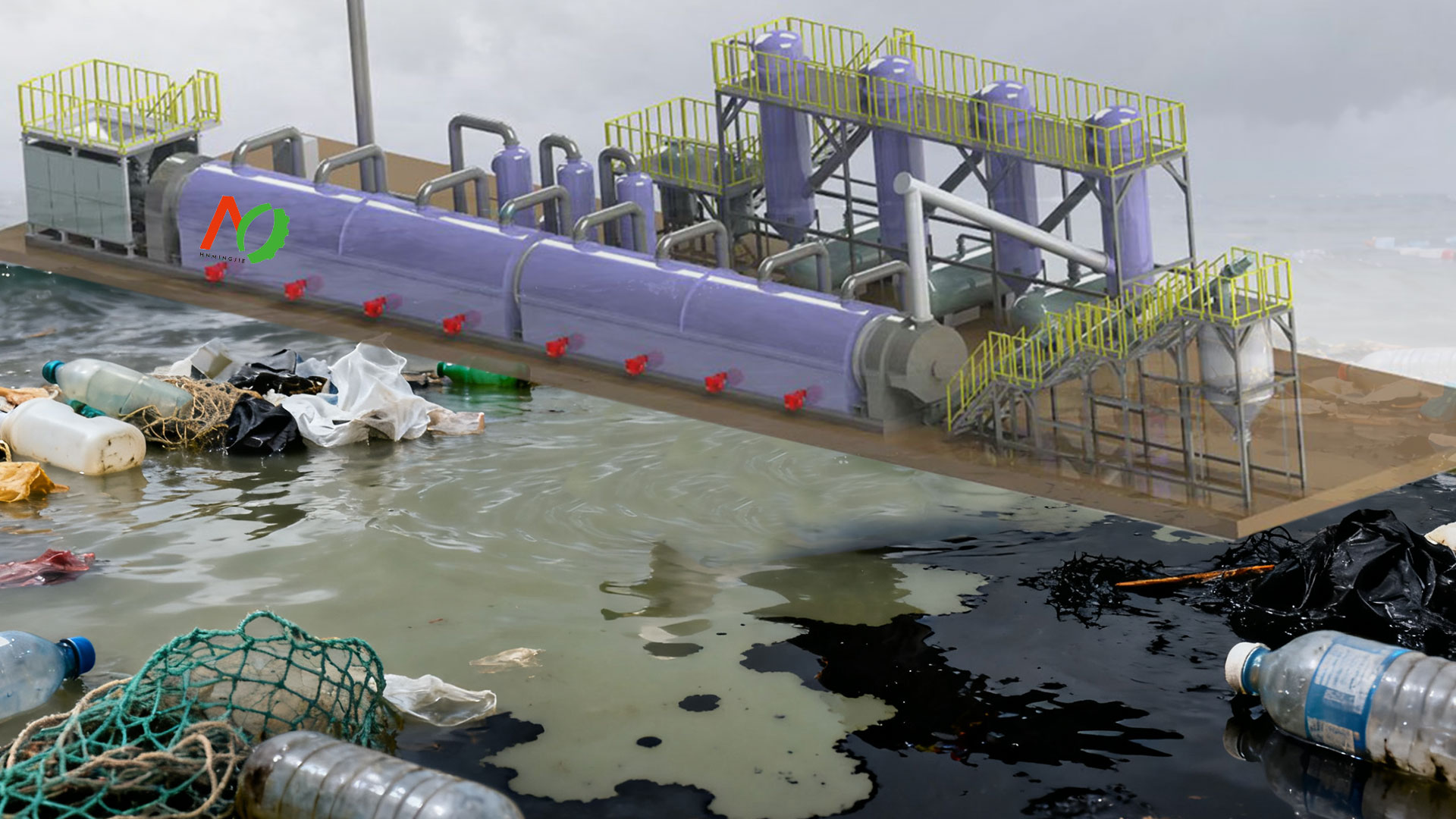

Mingjie provides batch, semi-continuous, and fully continuous pyrolysis equipment for Pyrolysis Solution for Plastic Pollution. Our pyrolysis plants enable the deep resource utilization of household plastic waste, marine plastic waste, and mixed plastic waste. The fully continuous pyrolysis equipment utilizes intelligent control systems, enabling large processing capacity, continuous operation, and high-value conversion.

According to relevant data, a medium-sized plastic pyrolysis plant can process tens of thousands of tons of waste plastic annually, producing thousands of tons of fuel oil and chemical raw materials. This not only effectively reduces the amount of plastic waste going to landfill but also provides a new source of raw materials for the energy and chemical industries.

As global awareness of plastic pollution continues to grow, pyrolysis technology, as an effective means of plastic pollution control, has been widely adopted and promoted worldwide. Pyrolysis technology plays a vital role in the treatment of marine plastic pollution, medical plastics, and household plastic waste, making a greater contribution to improving the global ecological environment.

Solutions for Plastic Pollution

Plastic pollution is everywhere. It’s more than just a visual issue, it’s a profound ecological and health crisis. Through a comprehensive approach that combines reduction, renewal, recycling, and cleanup, we have the power to reverse this crisis.

Plastic pyrolysis is an important development in the recycling sector. It complements mechanical recycling, and forms a key link in the treatment of mixed and contaminated plastic waste.

The core advantage of pyrolysis technology is its ability to process plastic waste that cannot be effectively processed by mechanical recycling, such as mixed plastics, contaminated plastics, and low-value plastics.

Advantages of Waste Plastic Pyrolysis Solution

Environmental Protection: The pyrolysis process for waste plastics occurs in the absence or anoxic conditions, eliminating the production of significant quantities of hazardous gases such as dioxins. Furthermore, it reduces the need for landfill and incineration of waste plastics, reducing pollution to soil, air, and water.

Resource Recovery: Pyrolysis equipment converts waste plastics into usable energy and chemical raw materials. This achieves resource recycling and improves resource utilization.

Economic Benefits: The fuel oil, syngas, and carbon black produced by plastic pyrolysis have significant market value and can generate significant economic benefits. Furthermore, it can reduce the cost of waste plastics disposal.