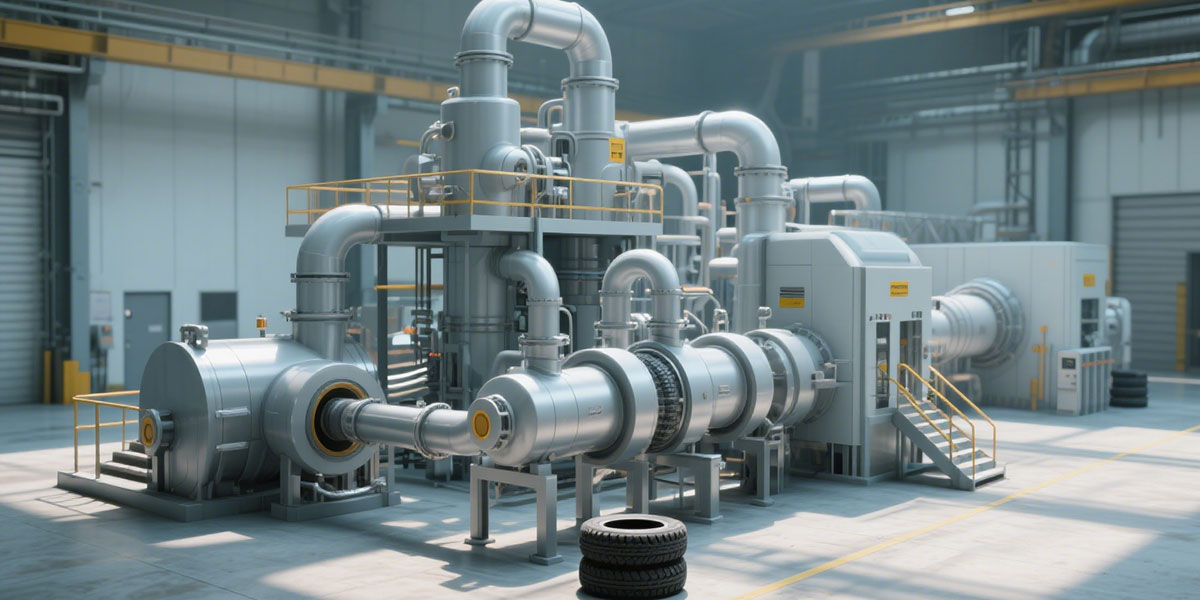

The fully continuous tire pyrolysis process refers to a waste tire processing technology with continuous feeding, continuous reaction and continuous discharging. In an oxygen-free or oxygen-deficient environment, the continuous pyrolysis plant decomposes the high molecular polymer (rubber) in the tire into more valuable products (pyrolysis oil, pyrolysis gas and solid carbon black) through high temperature, and recycles the steel wire in the tire.

The continuous pyrolysis plant adopts external heating, slight negative pressure, oxygen-deficient and continuous pyrolysis process. The fully continuous tire pyrolysis process has significant advantages such as high efficiency, low energy consumption, large processing volume, high degree of automation, stable product quality, and good environmental protection.

The fully continuous tire pyrolysis process uses real-time monitoring and automatic control. The tire pyrolysis oil yield is 40-45%, the carbon black yield is 30-35%, the combustible gas yield is 10%, the steel wire yield is 15%, the pyrolysis rate is >99%, and the waste heat utilization rate is >90%.

How to Achieve Fully Continuous Tire Pyrolysis Process

The fully continuous tire pyrolysis plant is the main equipment for realizing large-scale, industrialized, and resourceful utilization of waste tires. It is mainly composed of feeding system, pyrolysis system, oil-gas separation system, non-condensable combustible gas purification system, discharging system, PLC control system and circulating water cooling system.

Before entering the continuous pyrolysis reactor, waste tires need to be pre-processed by wire separation and crushing. The feed size of the fully continuous pyrolysis equipment is required to be less than 5-8mm, and the raw materials need to be crushed into rubber powder without stainless steel wire.

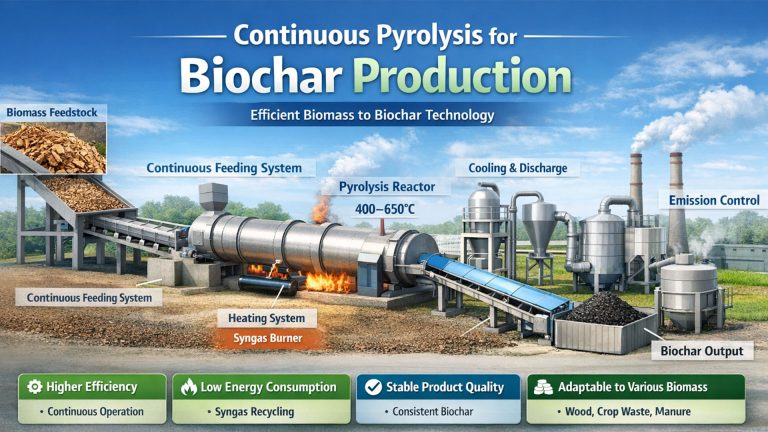

Continuous Feeding

The pre-treated tire fragments (rubber powder) are continuously and stably fed into the pyrolysis reactor through a sealed feeding device. This is one of the core technical difficulties of the full continuous tire pyrolysis process. It is necessary to ensure that the feeding process does not leak air (oxygen) into the reactor to prevent combustion or even explosion.

Continuous Tire Pyrolysis Process

The continuous pyrolysis reactor is the core equipment of the entire tire pyrolysis process. The burner starts to heat the reactor, and the reactor keeps rotating to ensure that the waste tires can be heated evenly. The tire rubber powder is heated to a specific temperature range in the reactor (the optimal temperature is between 450°C – 550°C), and a complex cracking reaction occurs in an oxygen-free or oxygen-deficient environment.

In the early stage of the pyrolysis reaction, the rubber molecules first decompose into low molecular weight polymer fragments. As the temperature rises, these fragments are further cracked into small molecular hydrocarbons to form fuel oil and combustible gas. The remaining solid residue is carbon black.

Separation of Tire Pyrolysis Products

After the pyrolysis reaction is completed, the tire pyrolysis products need to be collected and separated.

The oil and gas generated by tyre pyrolysis process are transported to the condensation system through the gas channel. It adopts a multi-stage cooling method. After cooling, the condensable components are condensed into liquid pyrolysis oil. The non-condensable gas (pyrolysis gas) continues to exist in gaseous form. The crude pyrolysis oil can be improved by waste oil distillation equipment.

The gaseous mixture produced by high-temperature pyrolysis is discharged from the top of the reactor. The separated non-condensable pyrolysis gas (mainly H₂, CH₄, CO) has a high calorific value and is a high-quality fuel gas. It provides heat for the pyrolysis reactor itself to achieve energy self-sufficiency. Excess syngas can be used to drive internal combustion engines or gas turbines to generate electricity.

The solid residue (mainly carbon black) remaining after tire pyrolysis process is discharged from the bottom or end of the reactor. The high-temperature carbon black residue needs to be cooled (water-cooled spiral or air-cooled) to a safe temperature.

Tail Gas Purification

The flue gas after combustion or a small amount of waste gas that is not fully utilized must undergo strict environmental protection treatment: such as cyclone dust removal, bag dust removal, spray tower, desulfurization and denitrification device, activated carbon adsorption, etc. The flue gas can only be discharged into the atmosphere after ensuring that it meets the emission standards.

Fully Automatic Tyre Pyrolysis Plant Manufacturer

Henan Mingjie Pyrolysis Plant Manufacturer provides technically and commercially proven machinery in the pyrolysis field, providing our customers with the main solutions in the pyrolysis field.

The fully automatic tire pyrolysis plant represents the advanced level and development direction of waste tire resource utilization technology. Through precise engineering design, strict process control and efficient energy utilization, it realizes the efficient, environmentally friendly and economical transformation of waste tires into fuel oil, fuel gas, carbon black and steel wire.

Our fully continuous pyrolysis plant adopts a fully automated control system, and the entire tire pyrolysis process is optimally configured under the control of an intelligent system. At the same time, it is equipped with proprietary waste heat utilization technology and multi-stage exhaust gas purification technology to greatly reduce energy consumption.