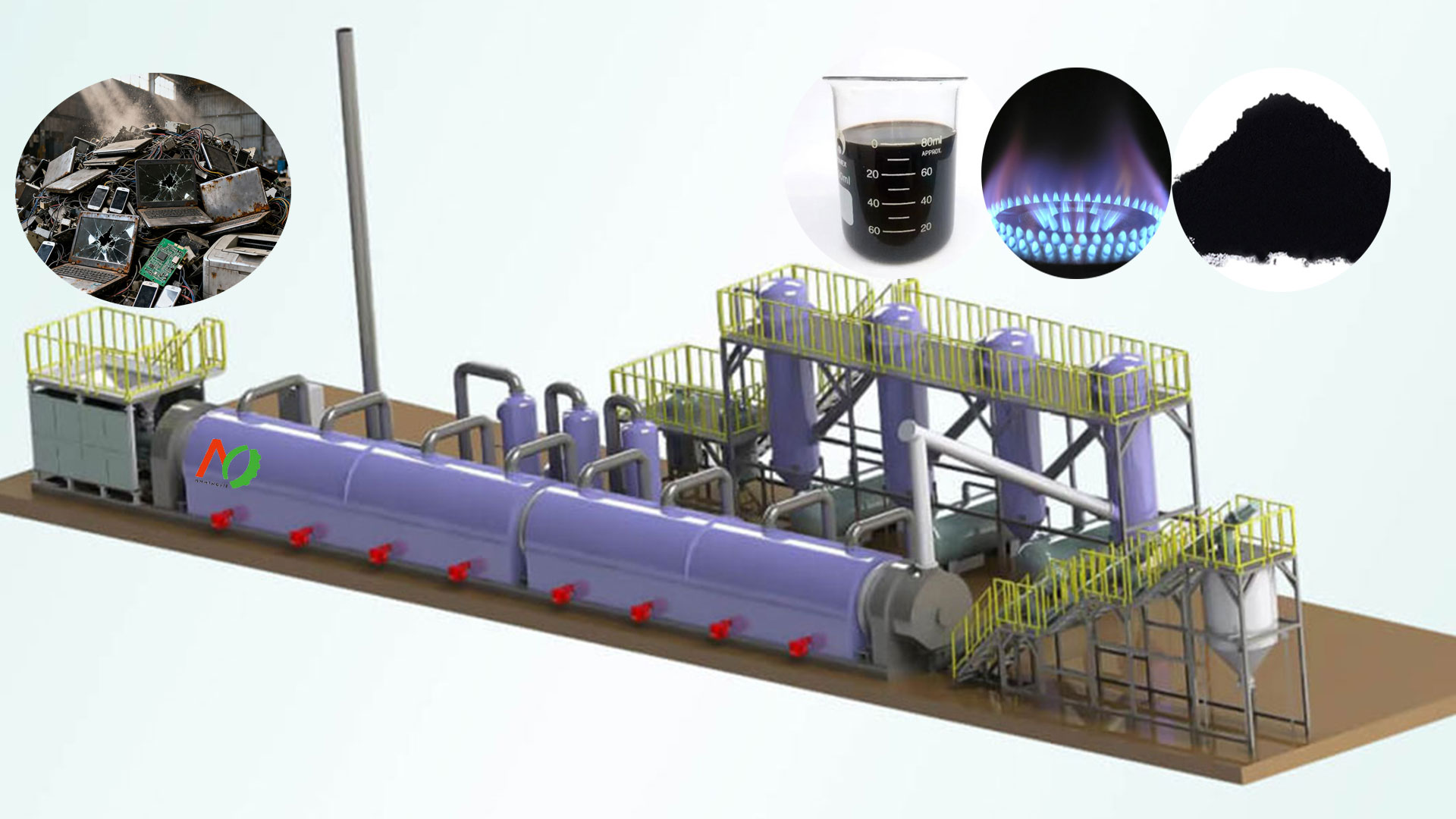

Electrical Waste Pyrolysis is a thermal decomposition process conducted under anaerobic conditions. This pyrolysis process of E-waste breaks down e-waste into pyrolysis oil, syngas, and solid residues. Pyrolysis plant can process various types of e-waste, including discarded computers, televisions, and smartphones. Its main advantage lies in its ability to recover valuable materials.

When electronic waste is fed into pyrolysis equipment, the temperature gradually rises, typically reaching 300-800℃ or even higher. During this process, the organic components in the electronic waste, such as plastics and rubber, first soften and melt.

As the temperature rises further, the chemical bonds of these organic substances begin to break, resulting in thermal decomposition. These decomposition products exhibit different forms in the pyrolysis environment based on their physical properties.

The main Electrical Waste pyrolysis products include combustible gases, liquid oil, and solid char. Combustible gases are rich in hydrogen (H₂), methane (CH₄), carbon monoxide (CO), etc.

Liquid oil contains various organic compounds, such as phenols and aromatics. After further distillation refining, pyrolysis oil can be used as fuel oil. It can also be used as a chemical raw material in the production of plastics, rubber, and other products.

Solid char has a rich porous structure and a large specific surface area, making it suitable as a raw material for activated carbon.

Advantages of Pyrolysis Electrical Waste

Among the many methods for treating electronic waste, Electrical Waste Pyrolysis pyrolysis stands out as a highly promising solution. Compared to traditional landfill and incineration methods, pyrolysis demonstrates significant advantages in both environmental protection and economics.

Environmental Advantages of Electrical Waste Pyrolysis

From an environmental perspective, Electrical Waste Pyrolysis pyrolysis excels in reducing pollution emissions. Traditional incineration, during high-temperature combustion, causes the organic matter in electronic waste to react fully with oxygen, producing large amounts of harmful gases. Pyrolysis is conducted in an oxygen-free or oxygen-deficient environment, inhibiting dioxin formation at its source.

A German study showed that using pyrolysis to treat electronic waste can reduce dioxin emissions by more than 90% compared to incineration. Emissions of other harmful gases, such as nitrogen oxides, generated during pyrolysis are also significantly reduced, effectively mitigating atmospheric pollution.

When processing waste circuit boards, incineration causes brominated flame retardants and other substances in the boards to decompose at high temperatures, producing harmful bromine-containing gases. Pyrolysis avoids this problem. The exhaust gas from pyrolysis, after simple purification, can meet stringent emission standards, significantly reducing air pollution.

Landfilling electronic waste also has many drawbacks. Heavy metals and organic pollutants in electronic waste gradually seep into the soil and groundwater over time. Pyrolysis technology can decompose and fix harmful substances in electronic waste, greatly reducing the risk of soil and water pollution. In the solid carbon produced by pyrolysis, heavy metals are fixed in the carbon’s crystal structure, greatly improving stability and reducing their migration and bioavailability in the environment.

Electrical Waste Pyrolysis can also significantly reduce land occupation. Traditional landfilling requires a large amount of land resources to store electronic waste. Solid waste pyrolysis machine can drastically reduce the volume of electronic waste. The Electrical Waste Pyrolysis solid products are only a fraction of the original electronic waste volume, or even smaller, greatly reducing the need for land. This not only saves valuable land resources but also avoids a series of environmental and social problems caused by land occupation.

Pyrolysis Of E-Waste Economic Advantages

Economically, Electrical Waste Pyrolysis pyrolysis technology has extremely high resource recycling value. Electronic waste is rich in various valuable metals and organic substances. Pyrolysis technology allows for the effective recycling and utilization of these resources.

Approximately 200 grams of gold, 2200 grams of silver, 100 kilograms of copper, and other rare metals can be extracted from each ton of discarded mobile phones. During pyrolysis, these metals are concentrated in the solid products or pyrolysis oil, which can be recycled and reused through subsequent separation and purification processes.

The Electrical Waste Pyrolysis products can be used directly as energy or further processed into high-value-added products. The combustible gas can be used for power generation and heating, providing energy support for the enterprise itself or the surrounding area. After distillation refining, the pyrolysis oil can be used as fuel oil in industrial boilers, engines, etc. Pyrolysis technology can also drive the development of related industries, creating more employment opportunities and economic benefits.